Edge grinding machine and arc deformation grinding method

An edger and grinding technology, applied in the direction of grinding feed motion, grinding drive device, grinding machine parts, etc., can solve the problem of shortened service life of grinding head, dirty processing environment, and increased product failure rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to achieve the above-mentioned purpose and effect, the technical means adopted in the present invention, its structure, and the method of implementation, etc., are hereby described in detail with respect to the preferred embodiments of the present invention. Its features and functions are as follows, so that it can be fully understood.

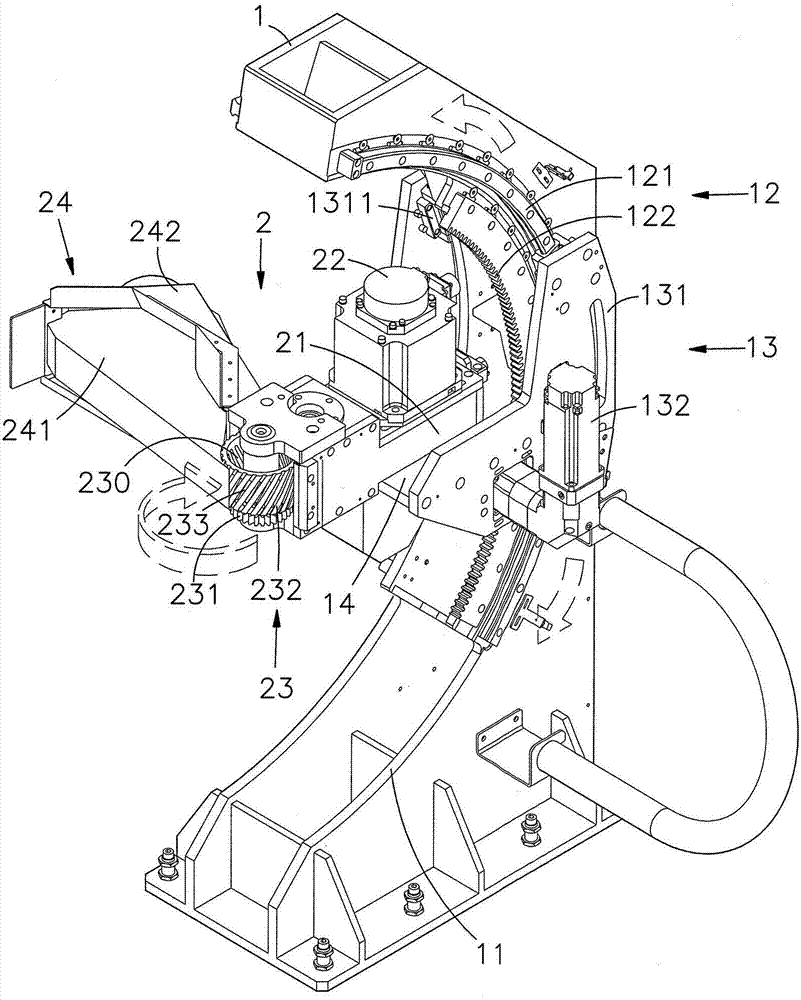

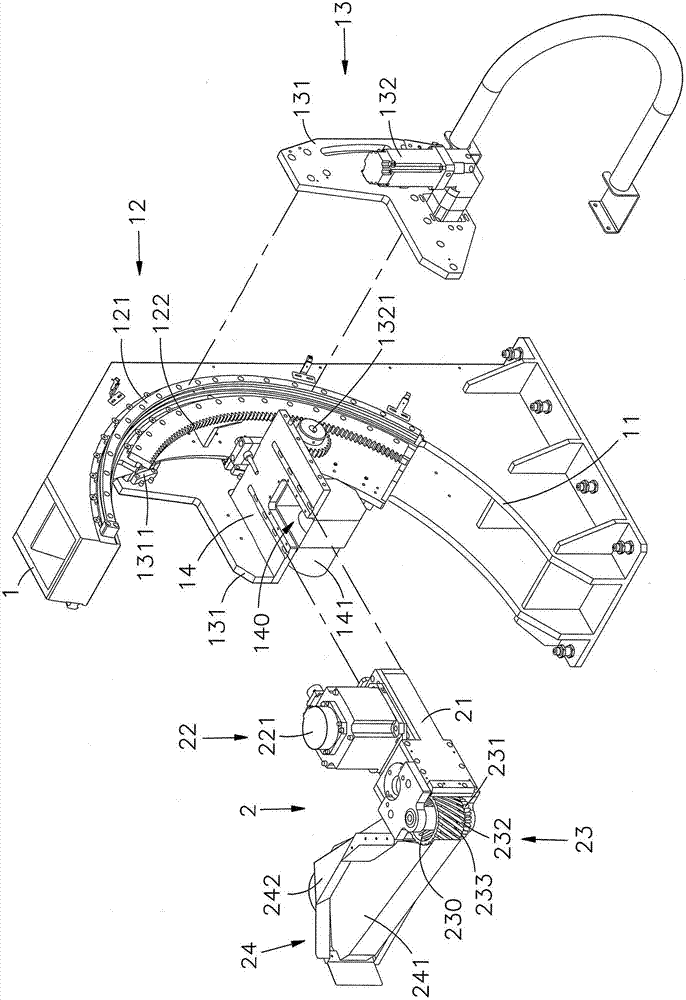

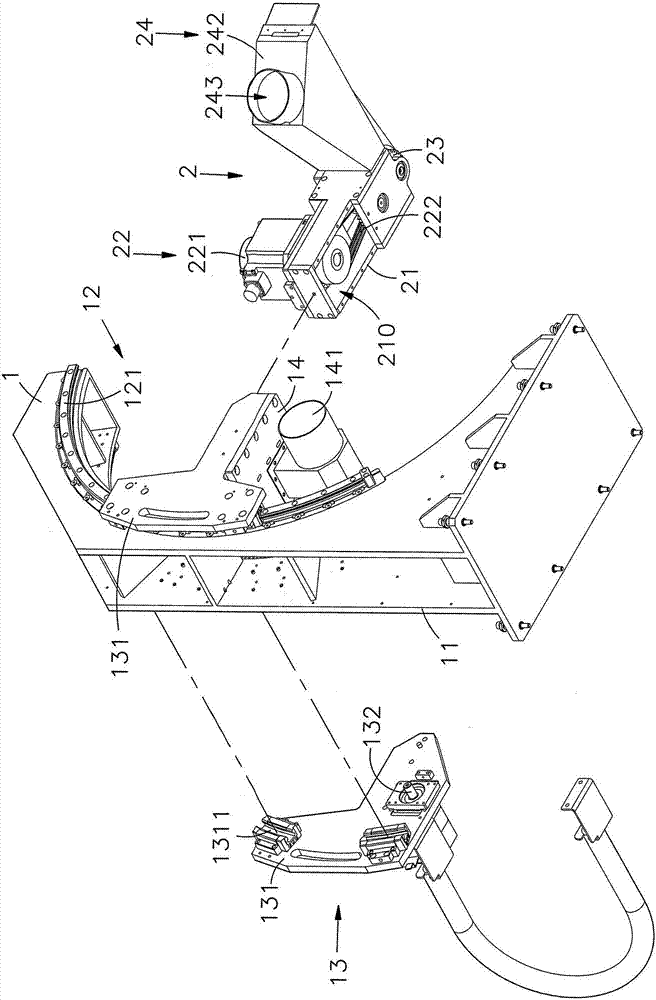

[0039] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown are the three-dimensional appearance diagram, the three-dimensional exploded view, the three-dimensional exploded view of another viewing angle, the three-dimensional appearance view of the grinding part, the three-dimensional exploded view of the grinding part, and the three-dimensional exploded view of the grinding part of another viewing angle of the present invention. It can be seen clearly that the edging machine of the present invention includes a base 1 and a grinding part 2, wherein:

[0040] The base 1 has an arc-shaped frame body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com