PDLC membrane module, manufacturing method and display device thereof

A manufacturing method and technology of membrane components, applied in optics, instruments, nonlinear optics, etc., can solve problems such as PDLC damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

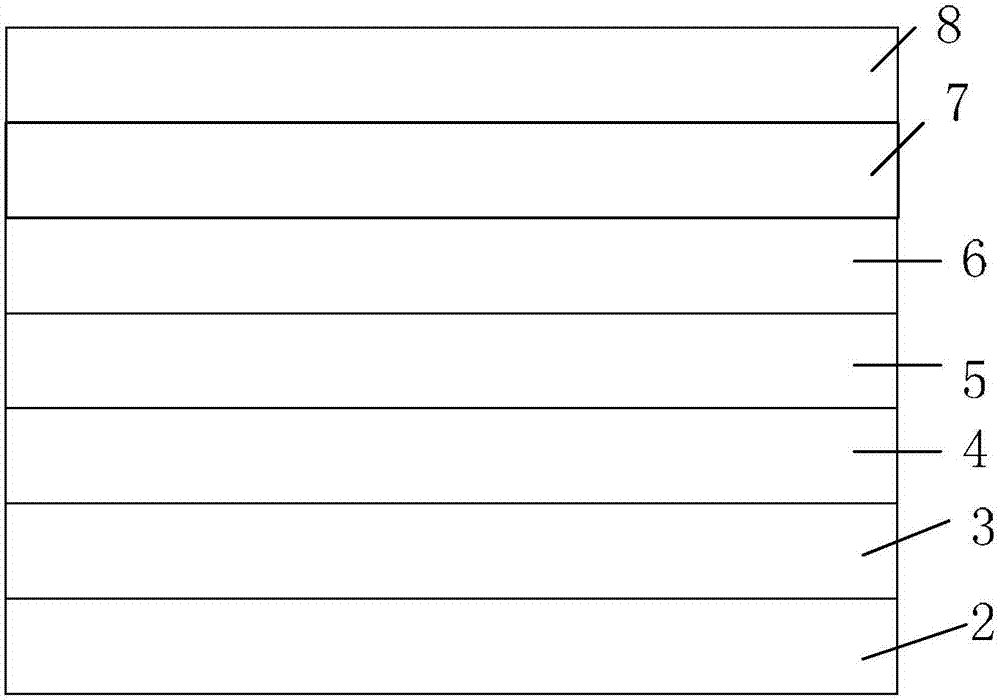

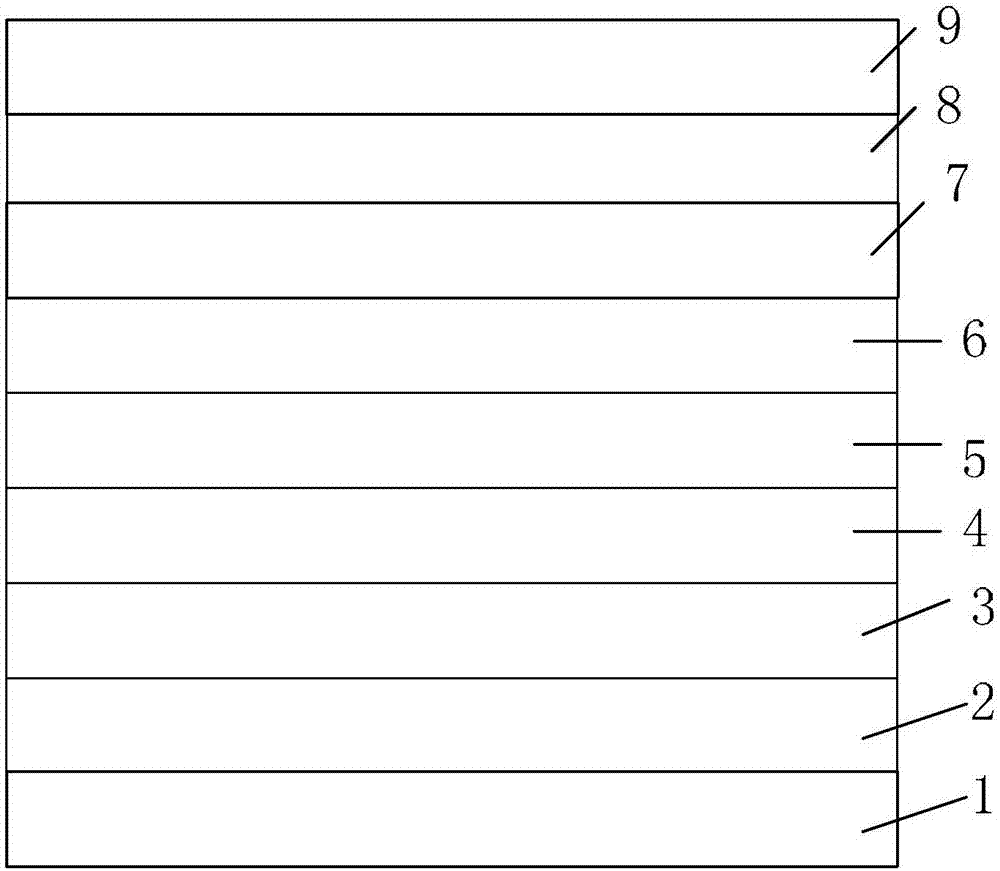

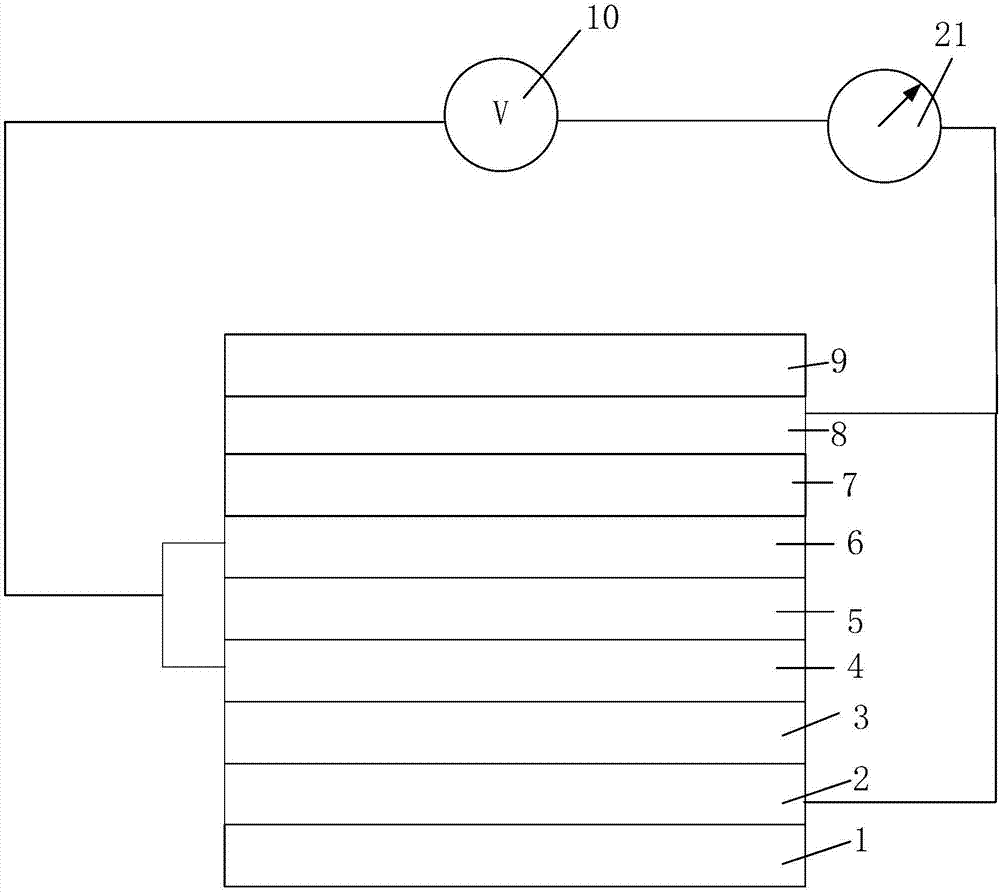

[0083] The specific structure is as Figure 4 As shown, the PDLC film assembly includes two above-mentioned PDLC films, the above-mentioned common transparent substrate layer 5 arranged between the two above-mentioned PDLC films, a power supply 10 and a first voltage regulator 21, and the two above-mentioned PDLC films are respectively the first A PDLC film and a second PDLC film, wherein the first PDLC film includes a first substrate layer 1, a first electrode layer 2, a first PDLC layer 3, and a second electrode layer 4 that are stacked in sequence, and the first PDLC layer 3 has a thickness of 10 μm, and the above-mentioned common transparent substrate layer 5 is arranged on the surface of the above-mentioned second electrode layer 4 away from the above-mentioned first PDLC layer 3; the second PDLC film is arranged on the above-mentioned common transparent substrate layer 5 far away from the above-mentioned first PDLC layer On the surface of a PDLC film, and the second PDLC...

Embodiment 2

[0089] The difference from Example 1 is that the public transparent substrate layer is a modified PS layer with a refractive index of 1.56; the thickness of the first PDLC layer is 15 μm, and the thickness of the second PDLC layer is 8 μm.

Embodiment 3

[0091] The difference from Example 2 is that the public transparent substrate layer is a modified PET layer with a refractive index of 1.50; the thickness of the first PDLC layer is 12 μm, the thickness of the second PDLC layer is 12 μm, and the polymer dispersed liquid crystal composition ( The specific formation process of PDLC is as follows:

[0092] Acrylic resin composition (48.25 g), liquid crystal BHR4030-RQ 002 (47.5 g), and spacer particles (0.25 g) having a particle diameter of 15 µm. After weighing in sequence according to the above proportions, place it in a yellow light place, then start stirring at room temperature, set the speed at 400-1000r / min, and wait for 0.5-1.5 hours after stirring. Weigh the wetting and dispersing agent TEGO670 (3g) and WO with a particle size of 30nm 3 (1g) and added in sequence, and continued to stir at room temperature for 0.5-2h to form an acrylic resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com