Oil supply device and lopper saw

A technology of oil supply device and high branch saw, which is applied in the directions of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of bulky oil supply device, affecting the operation of implementing tools, etc., achieves small size, avoids the influence of angle, structure Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides an oil supply device, such as Figure 6-Figure 9As shown, it includes an oil pump casing 1 and an oil pump plunger 2. The oil pump casing 1 is provided with a housing chamber for accommodating the oil pump plunger 2. The oil pump plunger 2 includes a driving part 21, a stroke limiting part 22 and an oil delivery part in sequence along its axial direction. Part 23, the oil delivery part 23 and the stroke limiting part 22 are all movably inserted in the accommodation chamber, and the side wall of the oil pump plunger 2 is sealed with the inner wall of the oil pump casing 1; the driving part 21 is connected with a driving device, and the driving device is used for The driving part 21 is driven to rotate in the circumferential direction; the oil pump casing 1 is provided with a stroke limiting device, which is used to limit the movement stroke of the stroke limiting part 22 along the axial direction of the oil pump plunger 2; the side wall of the oil...

Embodiment 2

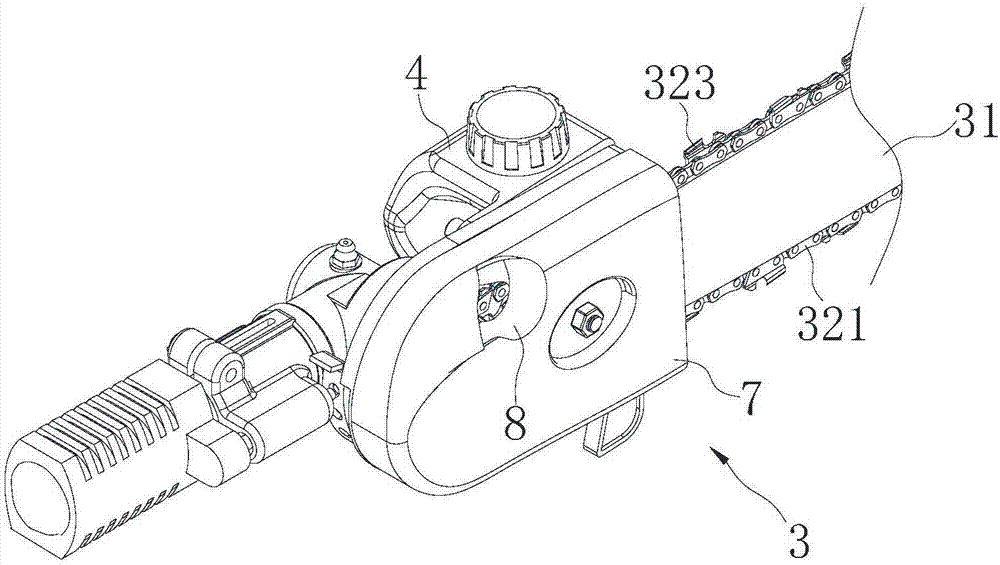

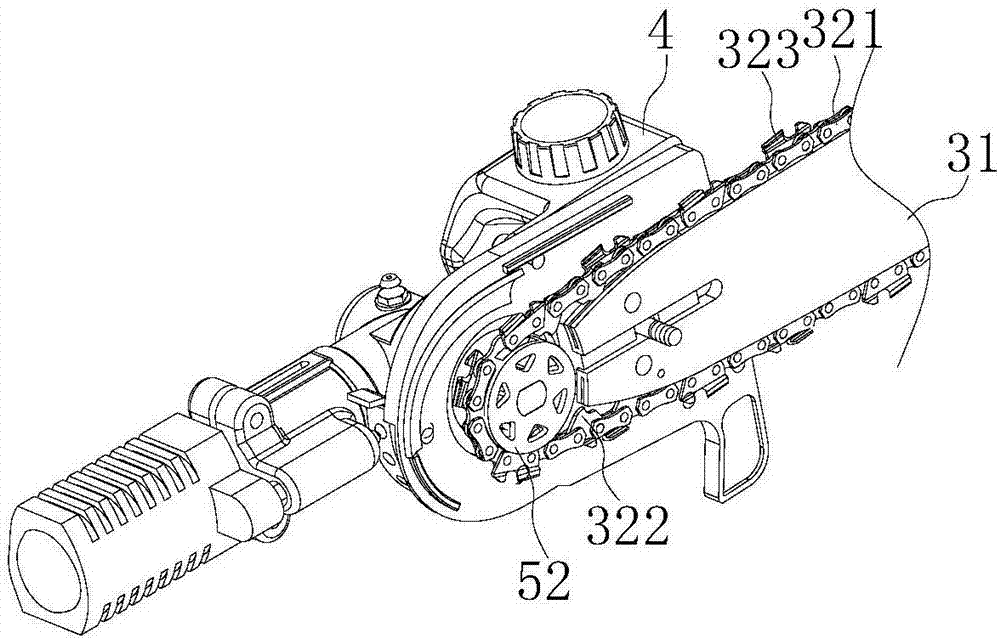

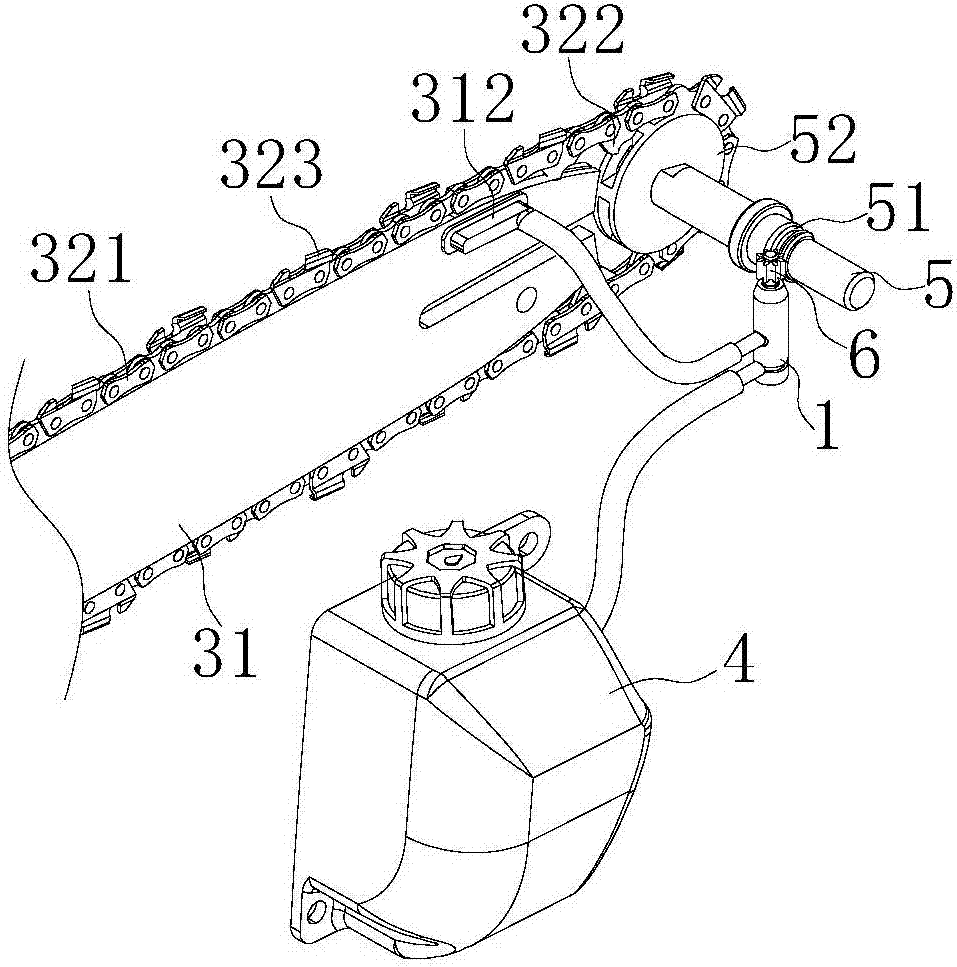

[0041] This embodiment also provides a high branch saw, such as Figure 1-Figure 3 , Figure 5 As shown, the saw head 3 and the oil supply device described in Embodiment 1 are included. The saw head 3 includes a guide plate 31, and the outer circumference of the guide plate 31 is provided with a guide groove 311 inwardly, and a chain 32 for cutting branches is clamped in the guide groove 311. , the guide groove 311 communicates with the oil outlet 12 of the oil supply device; the oil inlet 11 of the oil supply device communicates with the oil pot 4 through a pipeline.

[0042] The high-branch saw provided in this embodiment includes a saw head 3 for implementing tools. The saw head 3 includes a chain 32 for cutting branches, and the chain 32 is clamped on the outer periphery of the guide plate 31 . When the saw head 3 works, the chain 32 rotates around the guide plate 31 at high speed to cut the branches. The lubricating oil in the oil pot 4 enters the oil supply device from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com