Translational vulcanizer

A vulcanizing machine and vulcanizing chamber technology, used in tires, other household appliances, household appliances, etc., can solve the problems of shortening the life of the piston rod, affecting the operation stability and service life of the whole machine, and large stress deformation of the bracket.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

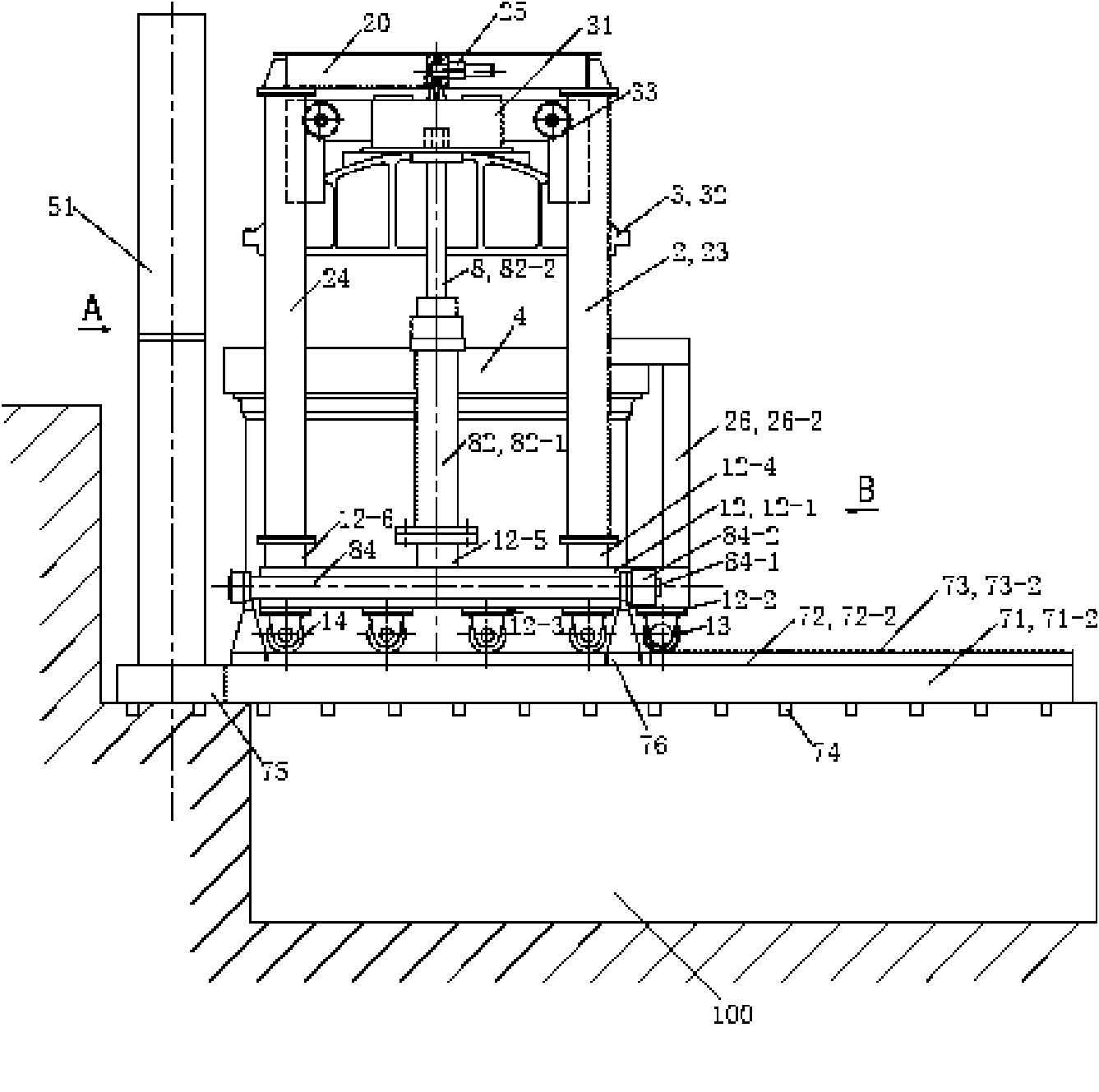

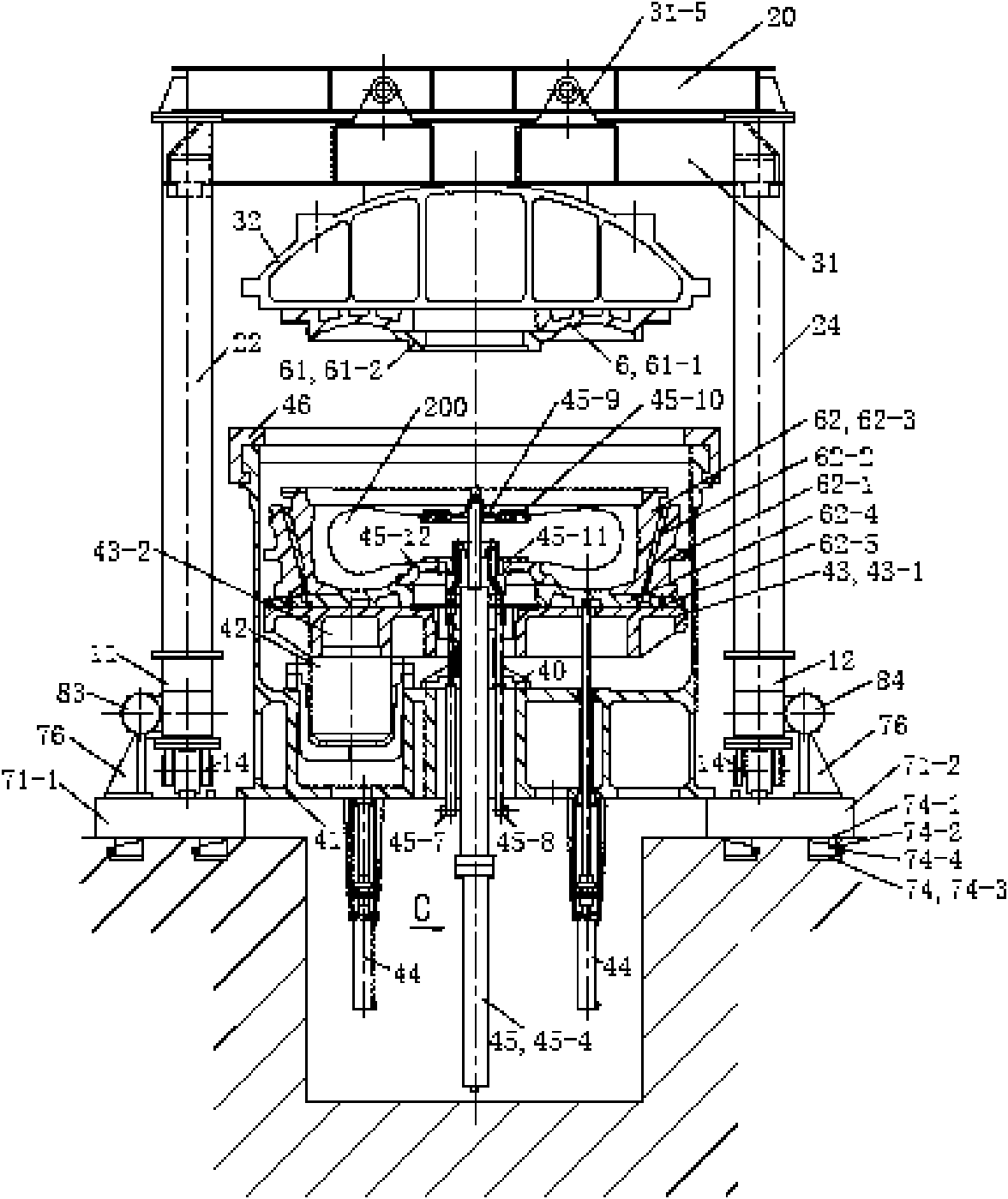

[0118] See Figure 1 to Figure 3 , the translation vulcanizing machine of this embodiment includes a translation mechanism 1, a translation frame 2, an upper vulcanization chamber 3, a lower vulcanization chamber 4, a tire loading and unloading device 5, a flexible mold 6, a base assembly 7, a mold opening and closing cylinder, a translation cylinder and a capsule 200. Movable mold 6 comprises upper mold 61 and lower mold 62; Translation oil cylinder comprises left translation oil cylinder 83 and right translation oil cylinder 84. The capsule 200 is purchased or manufactured directly by the tire manufacturer.

[0119] The machine base assembly 7 includes a machine base body 71 , a wheeled guide rail 72 , a rack 73 and an adjustment pad iron assembly 74 , a second machine base 75 and a translation cylinder support 76 . The base body 71 includes a left support frame 71-1, a right support frame 71-2, a front connecting frame 71-3 and a rear connecting frame 71-4. The left sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com