Novel method for preparing nano roughened PDMS (Polydimethylsiloxane) substrate

A new method, nanotechnology, applied in biochemical equipment and methods, bone/connective tissue cells, coatings, etc., can solve problems such as roughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

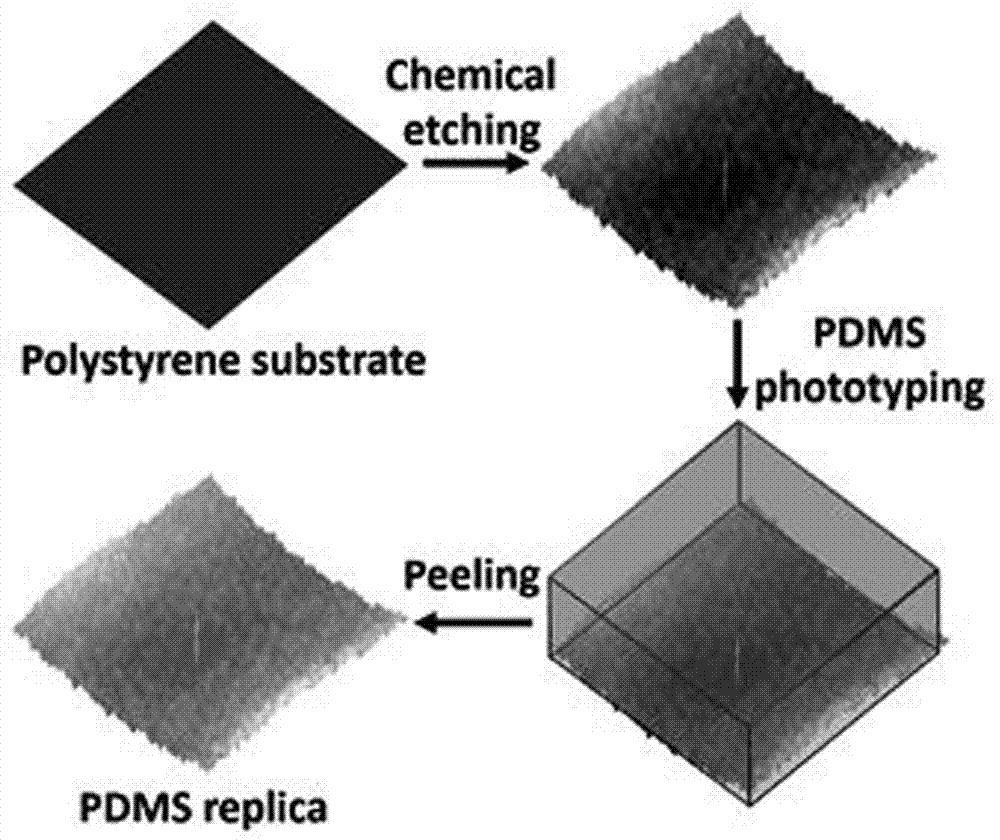

[0022] Example 1 Preparation of PDMS substrates with different nano-roughness

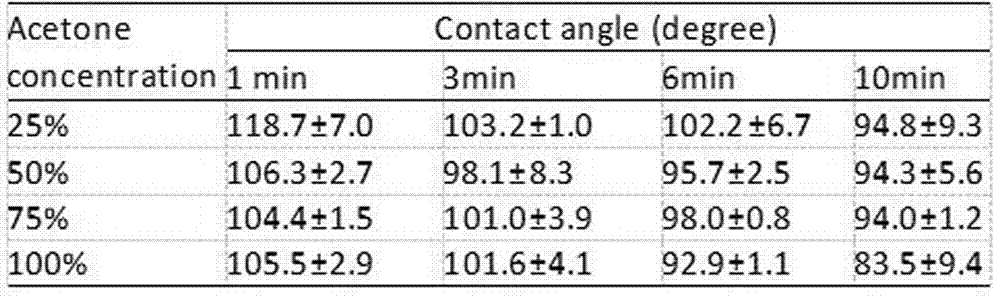

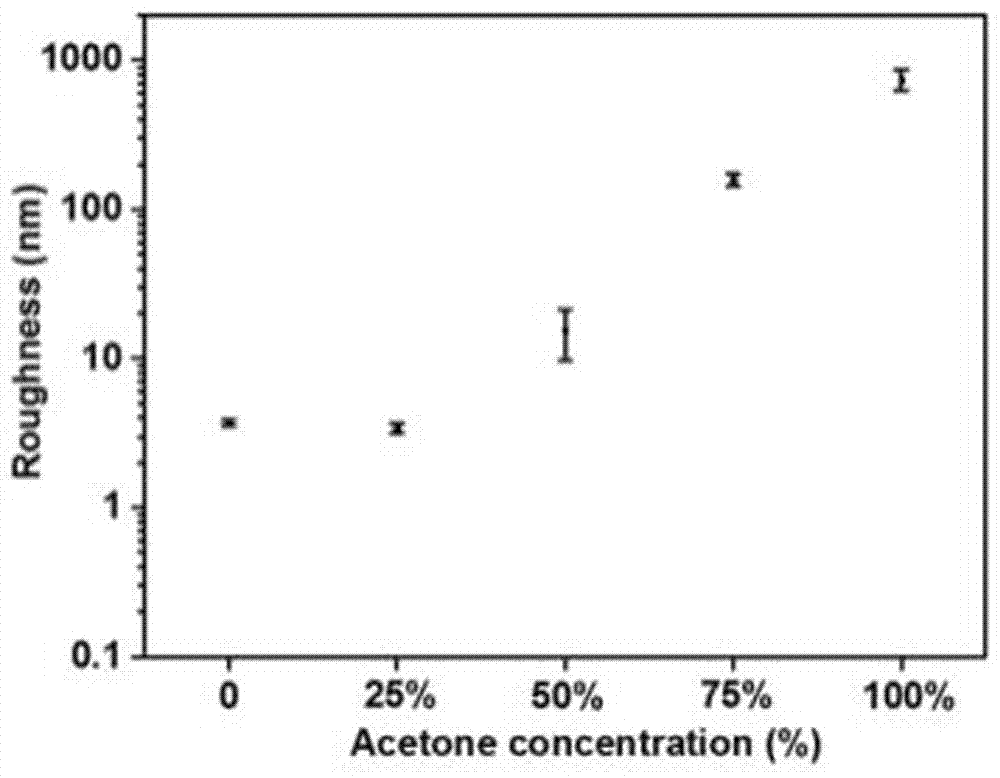

[0023] (1) Prepare the mold: use ethanol as the solvent, prepare acetone solutions with volume fractions of 25%, 50%, 75%, and 100%, respectively, pour these different concentrations of acetone into 24-well plates, and add 1mL to each well , and the action time was 1 min, 3 min, 6 min, and 10 min, respectively, thus producing 16 culture plate bases with different concentrations and action times.

[0024] (2) Preparation of PDMS with different nano-roughness: Mix the elastic agent and curing agent at a ratio of 10:1, stir evenly, then pour them into 16 different molds, remove air bubbles in vacuum for 1 hour, and then heat at 70 degrees for 2 hours , and then tear off the PDMS from the 24-well plate, and then use the elastic agent and the curing agent to configure the PDMS with a mass ratio of 10:1 to reversely adhere the 16 PDMS with different nanometer roughness to the new 24-well plate ,stand-by...

Embodiment 2

[0026] Example 2 Culture of mesenchymal stem cells on PDMS with different nano-roughness

[0027] (1) The mesenchymal stem cells were inoculated on two groups of PDMS substrates with different nano-roughness, respectively: 50% (1 min, 3 min, 6 min, 10 min) and 3 min (25 min). %, 50%, 75%, 100%) to test the cell adhesion after 4 hours, the results are as follows Figure 4 . The results showed that the greater the roughness, the greater the amount of cell adhesion. In addition, the activity of the cells was tested on the third day, the sixth day and the tenth day, and the results were as follows: Figure 5 , the results showed that with the increase of roughness, the cell growth was promoted gradually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com