Method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester

A technology of lubricating oil base oil and fatty acid ester, applied in lubricating composition, base material, petroleum industry and other directions, can solve the problems of unsuitability for large-scale industrial production, expensive catalyst, high production cost, and achieve good anti-wear performance , high viscosity index, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

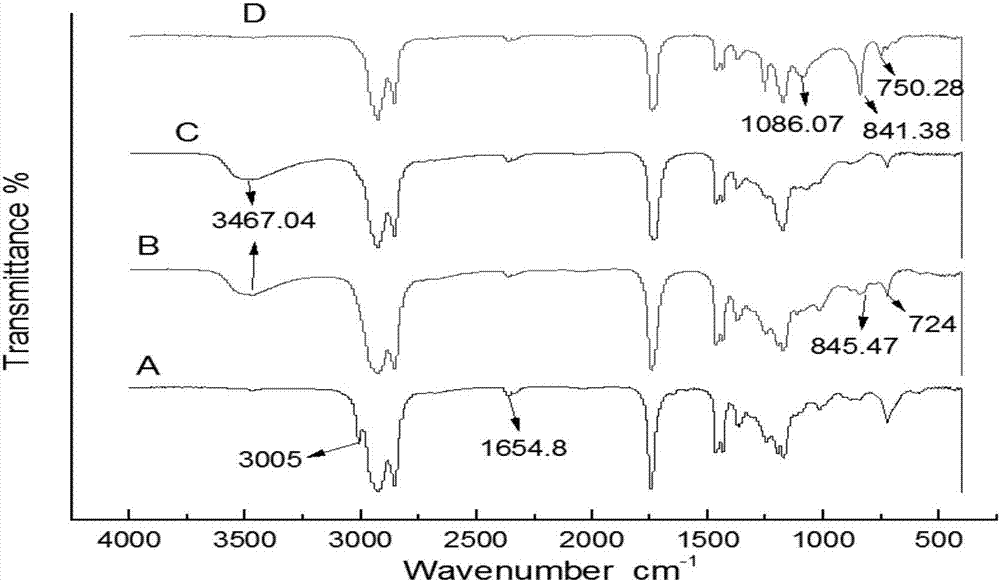

Method used

Image

Examples

Embodiment 1

[0030] Step 1 Mix 100g of methyl oleate with 23g of formic acid and 14g of NKC-9 cation exchange resin into the epoxy reaction kettle, slowly add 65g of hydrogen peroxide dropwise, react at 75°C for 2h, and let stand to separate after the reaction , Get the upper layer liquid and distill to obtain epoxy methyl oleate.

[0031] Step 2 Mix the epoxy fatty acid ester obtained in step 1 with 17.74 g of formic acid and add it to the ring-opening reaction device for reaction, stir and heat to 60 ° C for 2 hours, and wash with water to neutral vacuum distillation after the reaction to obtain the ring-opening product.

[0032] Step 3: Put 30 g of the ring-opened product obtained in step 2 into a three-necked flask with a thermometer, stir and heat to 40° C., and add 8.424 g of trimethylchlorosilane dropwise to the reaction system for 0.5 h; 10.02g of N,N-diisopropylethylamine was added dropwise to ensure that the system was alkaline. The reaction time was 2 hours. After the reaction w...

Embodiment 2

[0035] Step 1 mix 100g methyl linoleate with 13g formic acid, 4g solid acid Nb 2 o 5 Mix and add to the epoxy reaction kettle, slowly drop 95g of hydrogen peroxide, react at 55°C for 6h, after the reaction, stand and separate, take the upper liquid and distill to obtain epoxy linoleic acid methyl ester.

[0036] Step 2 Mix the epoxy fatty acid ester obtained in step 1 with 35 g of formic acid and add it to the ring-opening reaction device for reaction, stir and heat to 70° C. for 2 hours, and after the reaction, wash with water until neutral vacuum distillation to obtain the ring-opening product.

[0037] Step 3 Take 30g of the ring-opened product of methyl linoleate and put it into a three-necked flask with a thermometer, stir and heat to 45°C, and add 11.88g of bromotrimethylsilane dropwise to the reaction system, and the dropping time is 0.5 h; 6.12 g of pyridine was added dropwise to ensure that the system was alkaline, and the reaction time was 1.5 h. After the reaction ...

Embodiment 3

[0039] Step 1 Mix 100g of soybean oil, 25g of formic acid and 5g of titanium dioxide into the epoxy reactor, slowly add 85g of hydrogen peroxide dropwise, and react at 55°C for 6 hours. Oxygenated soybean oil.

[0040] Step 2 Mix the epoxidized soybean oil obtained in step 1 with 15 g of formic acid and add it to a ring-opening reaction device for reaction, stir and heat to 60° C. for 4 hours, and after the reaction, wash with water until neutral vacuum distillation to obtain a ring-opening product.

[0041]Take 30g of the ring-opened product of soybean oil and put it into a three-necked flask with a thermometer, stir and heat to 50°C, 10.53g of trimethylsilyl imidazole is added dropwise to the reaction system, and the dropping time is 0.5h; 7.84g Triethylamine was added dropwise to ensure that the system was alkaline, and the reaction time was 2.5 hours. After the reaction was completed, it was directly distilled under reduced pressure, and the solid was separated while it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com