Equipment system applicable to continuous capture of CO2 in flue gas of cement kiln

A technology of CO2 and cement kiln, which is applied in the capture of perfluorocarbons/hydrofluorocarbons, cement production, climate sustainability, etc., and can solve the problems of complex structure, insufficient cleanliness, and high cost of the capture device. , to achieve the effect of simple equipment structure, no secondary pollution, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

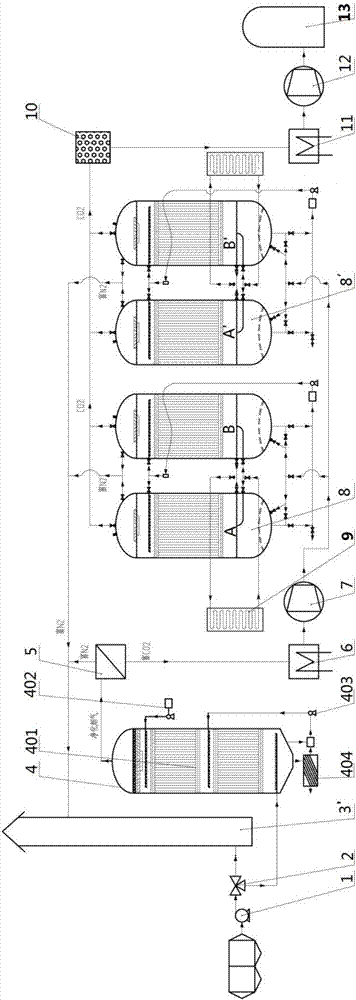

[0042] figure 1 It is applicable to the CO in the cement kiln flue gas proposed for the first embodiment of the present invention 2 Schematic diagram of the equipment system for continuous capture. figure 2 for figure 1 The proposed method is suitable for CO in cement kiln flue gas 2 CO in continuous capture systems 2 Schematic diagram of the structure of the circulation capture tower. image 3 for figure 1 The proposed method is suitable for CO in cement kiln flue gas 2 Schematic diagram of the structure of the atomizing spray device in the continuous capture equipment system. Figure 4 for figure 1 The proposed method is suitable for CO in cement kiln flue gas 2 Schematic diagram of the cooling / heating device in the continuous capture equipment system.

[0043] see Figure 1 to Figure 4 , suitable for CO in cement kiln flue gas 2 Continuous capture equipment system, including kiln exhaust fan 1, chimney 3, flue gas oxidation purifier 4, N 2 / CO 2 Membrane separ...

Embodiment 2

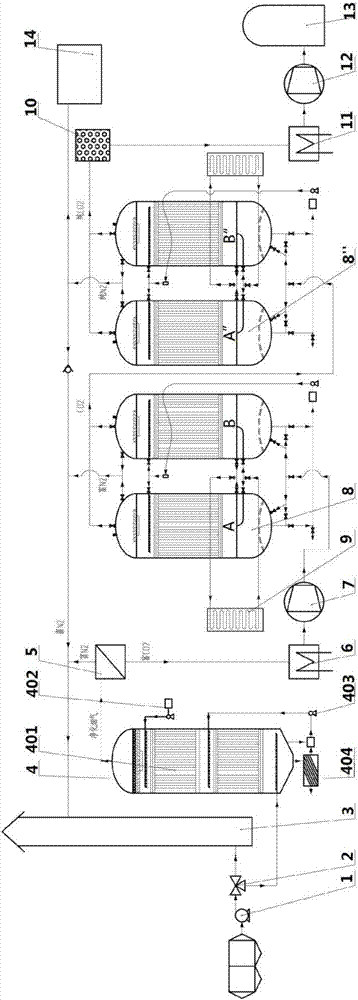

[0064] Figure 5 It is applicable to CO in cement kiln flue gas proposed for the second embodiment of the present invention 2 Schematic diagram of the equipment system for continuous capture.

[0065] see Figure 5 , the difference between the second embodiment and the first embodiment is that the CO 2 The circulation capture tower includes the same structure and is arranged in parallel by the CO 2 Circulation trap A and CO 2 There are two sets of circulating catchers B, the first set of CO 2 Circulation capture tower 8 includes CO 2 Circulation trap A and CO 2 Circulation trap B, second set of CO 2 Circulation capture tower 8' including CO 2 Circulation trap A' and CO 2 Circulating trap B', each of the CO 2 N-enriched in circulating traps (A, B, A', B') 2 The gas exhaust pipe is connected to the chimney or N 2 storage tank, each of the CO 2 CO in recirculating traps (A, B, A', B') 2 The discharge pipeline communicates with the dehydration dryer in sequence.

[...

Embodiment 3

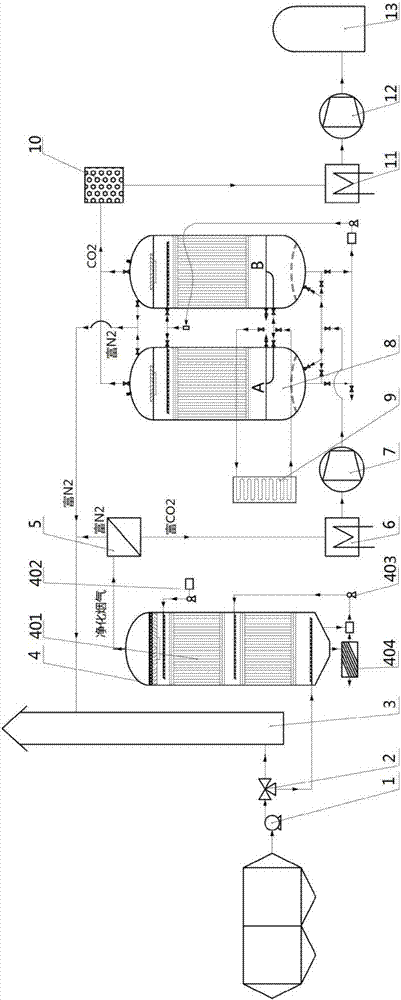

[0069] Image 6 It is applicable to CO in cement kiln flue gas proposed for the third embodiment of the present invention 2 Schematic diagram of the equipment system for continuous capture.

[0070] see Image 6 , the difference between the third embodiment and the first embodiment is that the CO 2 The circulation capture tower includes the same structure and is arranged in series by the CO 2 Circulation trap A and CO 2 There are two sets of circulating catchers B, the first set of CO 2 Circulation capture tower including CO 2 Circulation trap A and CO 2 Circulation trap B, second set of CO 2 Circulation capture tower including CO 2 Circulation trap A" and CO 2Circulation trap B", the flue gas compressor is first connected to the first set of CO 2 Circulation capture tower, the first set of the CO 2 N-rich in circulating trap tower 2 The gas exhaust pipe is connected to the chimney or N 2 Storage tank, first set of CO 2 CO from the cycle capture tower 2 The disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com