Flame-retardant composition and flame-retardant synthetic resin composition

A synthetic resin and composition technology, applied in the direction of fireproof coatings, etc., can solve the problems of insufficient handling, storage stability, and dust generation, and achieve excellent handling, storage stability, and excellent resistance. flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~7

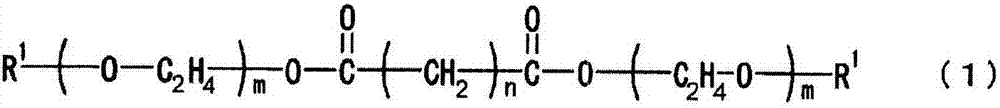

[0173] According to the compounding ratio described in Table 1, each component was mixed for 20 minutes at the rotation speed of 1500 rpm / min using the Henschel mixer, and the flame retardant composition powder of Examples 1-9 was prepared. (D) As an aliphatic dicarboxylic acid ether ester compound represented by the said general formula (1) of a component, compound No. 1 of the following structure was used.

[0174]

[0175] Similarly, flame retardant composition powders of Comparative Examples 1 to 7 were prepared according to the proportions described in Table 2. In the comparative example, in order to compare with the silane coupling agent of the component (C) of the example, the comparative example using silicone oil was implemented, and in order to compare with the compound No. 1 of the component (D) of the example, the use of glycerin was implemented. Comparative example of monostearic acid ester.

[0176] In order to evaluate the handling properties of the flame re...

Embodiment 10~20 and comparative example 8~17

[0185]0.1 parts by mass of calcium stearate (lubricant), tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propane, Acid methyl ester] methane (phenolic antioxidant) 0.1 mass part, tris (2,4-di-tert-butylphenyl) phosphite (phosphorus antioxidant) 0.1 mass part, glycerin monostearate (lubricant ) 0.3 parts by mass to obtain a polypropylene resin composition, to which the polypropylene resin composition was added the flame retardant composition obtained in Examples 1 to 9 according to the compounding ratio (mass %) recorded in Table 3 to obtain Example 10 ~20 flame retardant synthetic resin composition. Incidentally, regarding the flame retardant composition, the flame retardant composition obtained in Example 1 was used as the flame retardant composition-1, and the flame retardant composition obtained in Example 2 was used as the flame retardant composition Substance-2 was carried out in the same manner below, using the flame retardant composition-9 obtained up to Example 9.

[0...

Embodiment 21~29 and comparative example 18~26

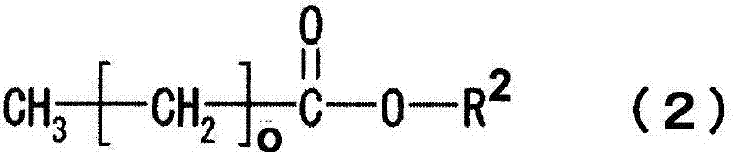

[0208] According to the compounding ratio described in Table 5, each component was mixed for 20 minutes using the Henschel mixer at the rotation speed of 1500 rpm, and the flame retardant composition powder of Examples 21-29 was prepared. (E) As an aliphatic carboxylic acid ester compound represented by the said general formula (2) of a component, compound No. 23 of the following structure was used.

[0209]

[0210] Similarly, flame retardant composition powders of Comparative Examples 18 to 26 were prepared according to the compounding ratio described in Table 6. In the said comparative example, in order to compare with the aliphatic carboxylic acid ester compound of (E) component of an Example, the comparative example which used glycerol monostearate was also implemented.

[0211] In order to evaluate the handling properties of the flame retardant composition powder obtained above due to the influence of dust, dust was evaluated by the following dust test method. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com