Plastic molded body

A plastic molding, concave and convex technology, applied in the direction of covering/exterior paint, other household appliances, transportation and packaging, which can solve the problem of reduced, reduced leakage and liquid rolling, unavoidable leakage and liquid rolling. problems such as falling properties, to achieve the effect of ensuring liquid rolling, ensuring liquid leakage, and stabilizing liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] The following examples are provided to illustrate the excellent properties of the present invention.

[0129] (1) Substrate;

[0130] *Material: Low Density Polyethylene

[0131] Grade: LJ8041 (Japan Polyethylene Corporation)

[0132] *Dimensions: 58mm(length)×58mm(width)×3mm(thickness)

[0133] (2) impression;

[0134] ·Production method:

[0135] ·One-time concave-convex impression

[0136] A master was fabricated by photolithography to obtain a stamp with primary concavities and convexities etched by Ni electroforming.

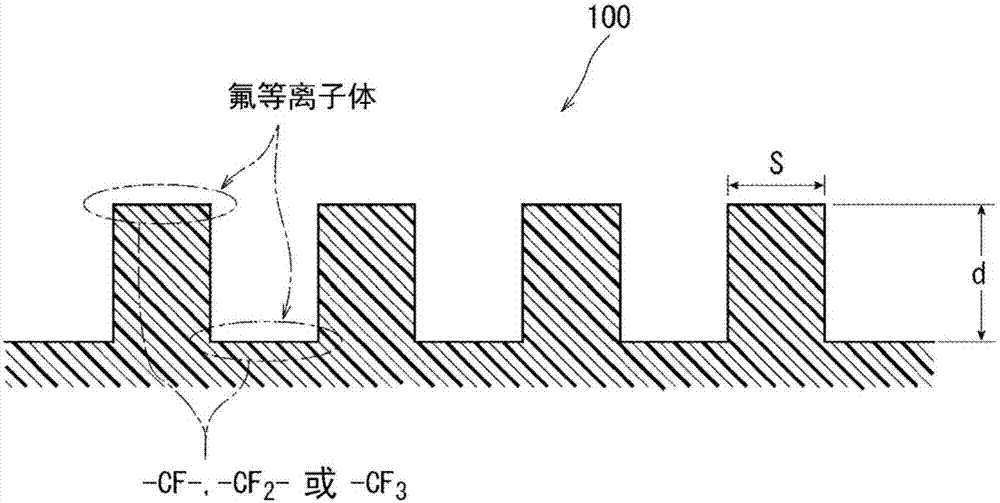

[0137] ·A bump

[0138] φ s =0.2 (s=20μm, d=30μm, pitch=100μm)

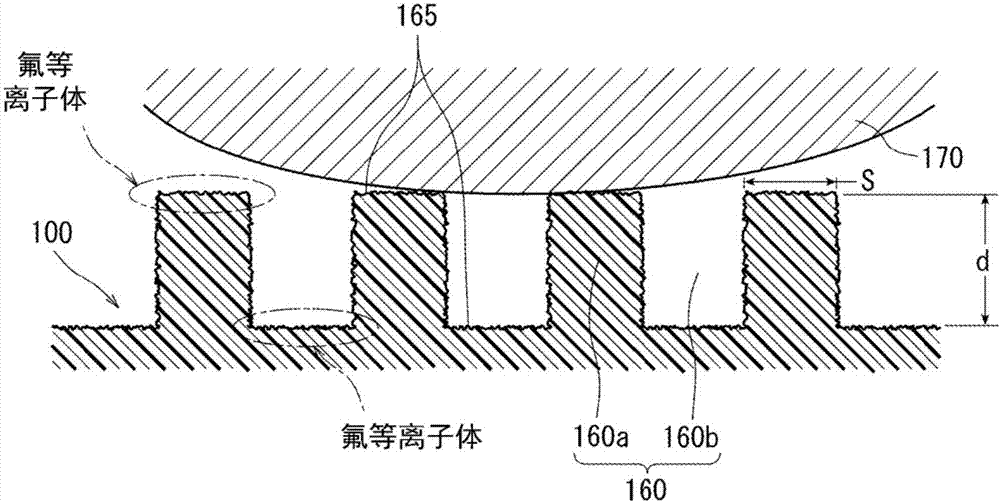

[0139] ·Secondary concave-convex impression

[0140] A master mold produced by Cu electroforming was wet-etched to form a rough surface, so that a stamp having secondary unevenness engraved by Ni electroforming was obtained.

[0141] ·Secondary bump

[0142] Ra / RSm=264×10 -3

[0143] (Ra=933nm, RSm=3.5μm)

[0144] · Fractal impression with primary bump + secondary bump

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com