Multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method

A technology of SCR catalyst and multi-source information fusion, which is applied in chemical analysis by catalysis, chemical process analysis/design, special data processing application, etc. It can solve uneven distribution, difficult catalyst life degradation, and denitrification that cannot represent the reactor Performance and other issues to achieve the effect of improving accuracy and stability

Active Publication Date: 2017-08-29

SOUTHEAST UNIV +1

View PDF2 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, due to the generally uneven distribution of the flow field, fly ash field, and flue gas composition field in the furnace, the degradation rates of catalysts at different positions in the same layer are also different. Therefore, the activity of the catalyst test sample cannot represent the entire layer of catalysts. and even the denitrification performance of the whole reactor

Second, the problem of the number of sample detection

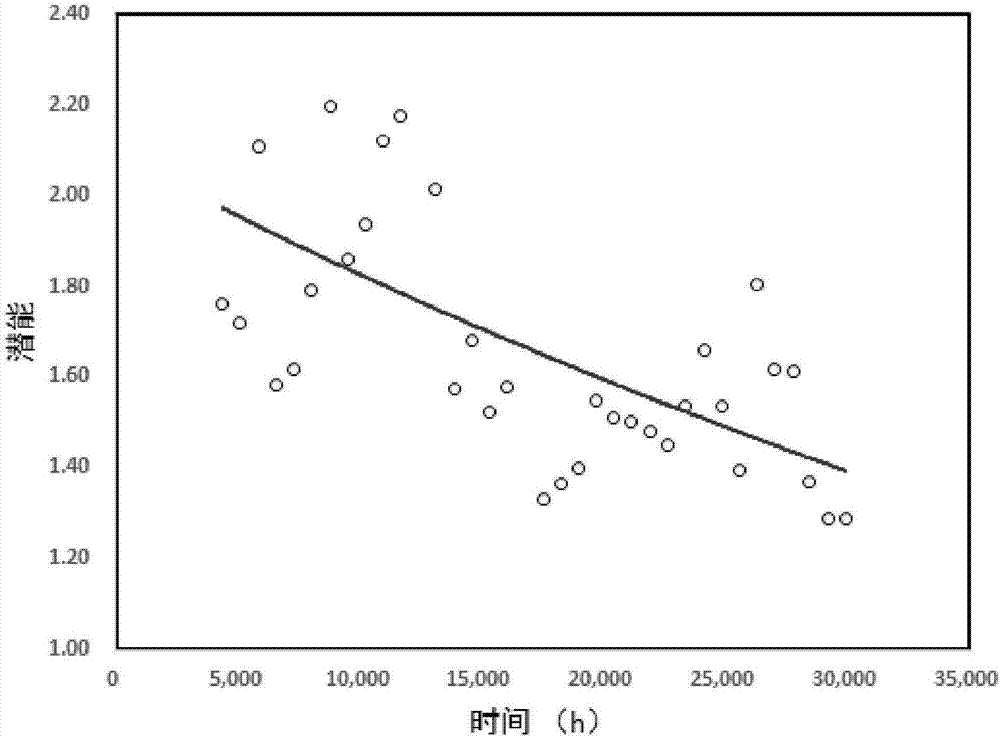

However, the operating conditions of the power plant fluctuate frequently, and the data is unstable and mixed, making it difficult to capture a stable catalyst life degradation trend

To sum up, the current catalyst life prediction methods can capture catalyst degradation information from their own perspectives, but they also have their own limitations. Therefore, it is urgent to propose a method to fuse these dispersed catalyst degradation information.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

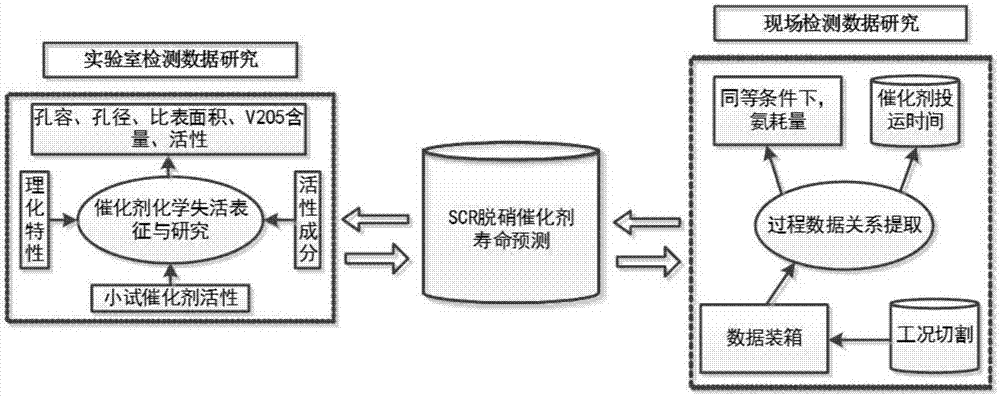

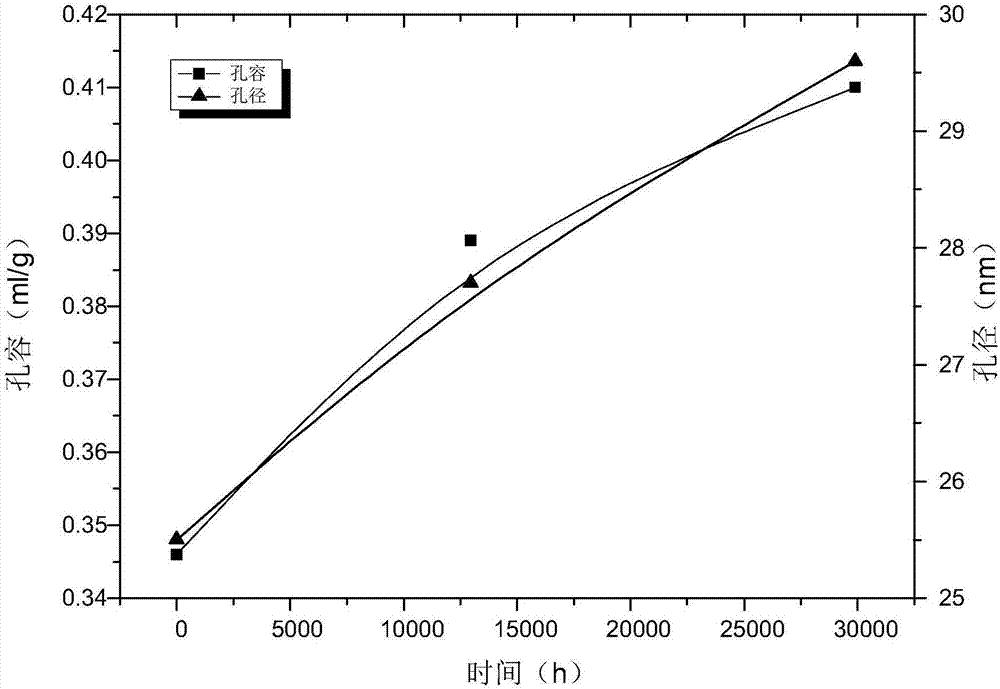

The invention provides a multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method. The multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method includes the following steps: performing multiple sampling on a catalyst used in a power station boiler, performing laboratory detection on a sample, and acquiring a microscopic feature index capable of representing the activity of the catalyst; acquiring a macro-performance index of the catalyst sample through a micro reactor test; counting and mining power station historical operation data to acquire a macro index capable of reflecting the power station SCR reactor performance; and fusing the indexes associated with the catalyst life, and completing comprehensive evaluation of the catalyst life. The evaluation method can acquire a catalyst life prediction model according to historical laboratory detection data and an actual operation parameter of the catalyst through a fuzzy mathematical method, and can improve the accuracy and stability of catalyst performance evaluation.

Description

Life evaluation method of coal-fired boiler SCR catalyst based on multi-source information fusion technology technical field The invention relates to the technical field of life management of SCR denitrification catalysts in coal-fired power plants, in particular to a method for evaluating the life of SCR catalysts in coal-fired boilers based on multi-source information fusion technology. Background technique In the coal-fired boiler SCR system, the activity of the catalyst is continuously reduced. At present, the German VGB and American EPRI standards are based on the traditional laboratory testing method for catalyst life prediction, that is, the catalyst manufacturer will arrange a test block in the catalyst, and when it is necessary to test the activity of the catalyst, the test block or the field collected Catalyst samples were taken out and sent to specialized laboratories for testing. However, this method has two disadvantages: first, the problem of sample represen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F19/00G01N31/10

CPCG01N31/10G16C20/10

Inventor 李树洲司风琪张贝范伟喻聪江晓明

Owner SOUTHEAST UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com