Nonionic epoxy active emulsifier, preparation method of nonionic epoxy active emulsifier and waterborne epoxy resin emulsion

A water-based epoxy resin, active emulsifier technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as environmental pollution and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

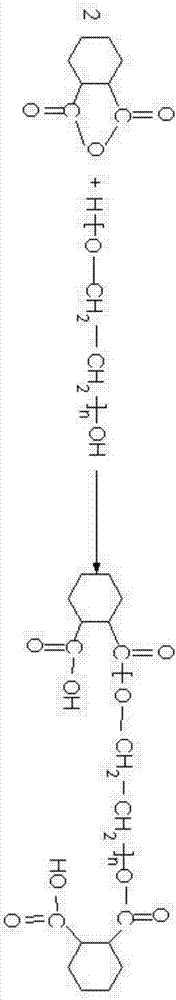

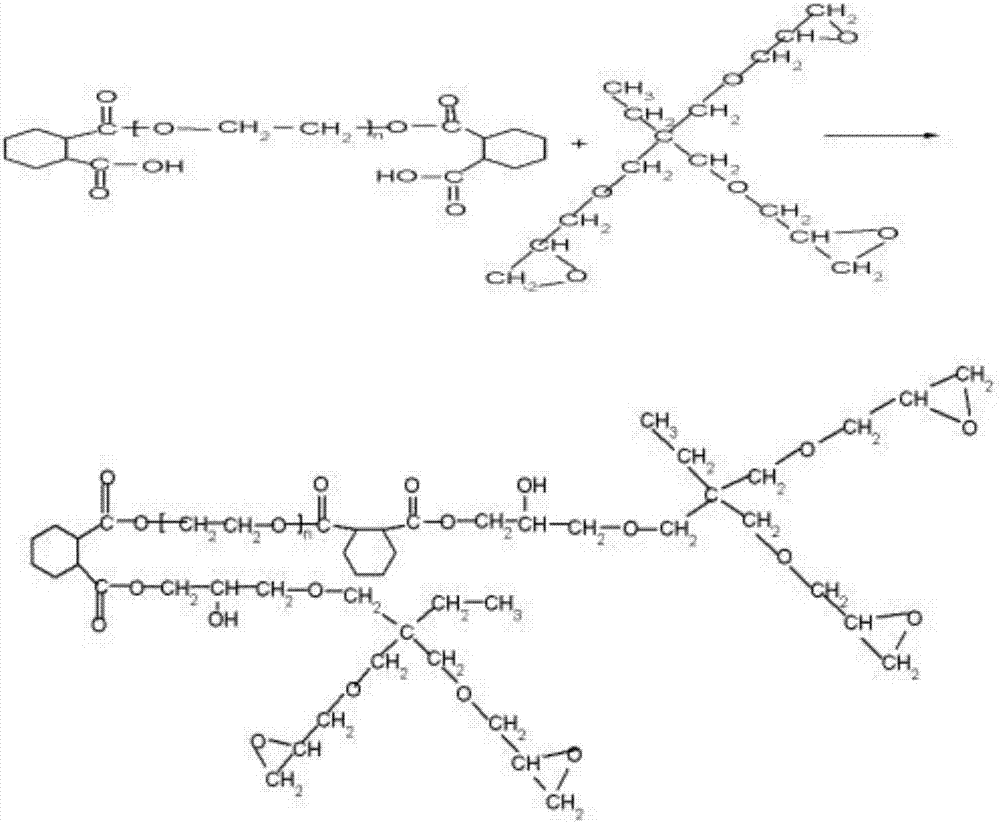

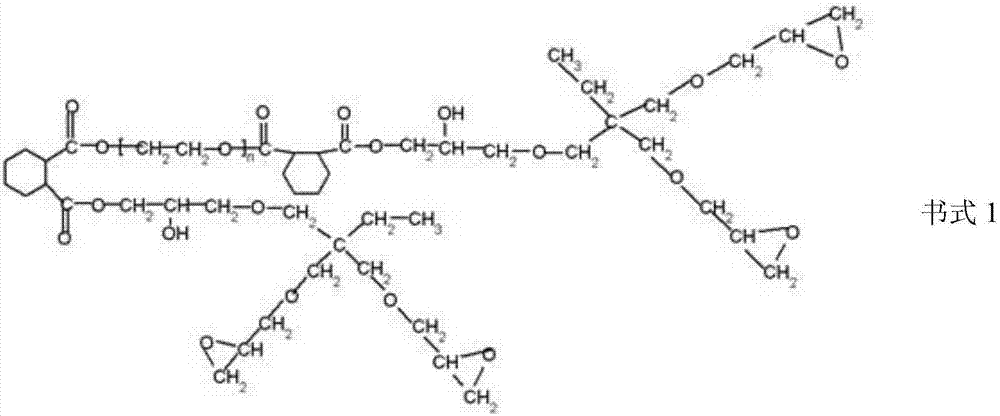

[0028] Embodiment 1 This embodiment relates to the synthesis of HHPA-P-TMPGE

[0029] Add 180.00g (30mmol) PGE6000 and 9.24g (60mmol) HHPA to a 500ml four-neck flask, put it under reflux and under a nitrogen atmosphere, heat and stir to mix the raw materials evenly, add 0.5g (0.3wt%) p-toluenesulfonic acid The above reaction solution was kept at a temperature of 90°C, and the acid value was tested every 0.5h, and the esterification rate was calculated. Reaction 4h. Then add 12.78g (30mmol) TMPGE to the system under the action of catalyst p-toluenesulfonic acid (no need to add catalyst), continue to react for 4h at a temperature of 110°C, and test the epoxy equivalent every 0.5h to calculate the epoxy conversion Rate. Finally, HHPA-P-TMPGE was obtained.

[0030] Equipment routes such as figure 1 and figure 2 shown.

Embodiment 2

[0031] Embodiment 2 This embodiment relates to the preparation of aqueous epoxy resin emulsion

[0032] Add the HHPA-P-TMPGE and E-21 prepared in Example 1 into a 500ml four-necked flask at a ratio of 15:85, heat to 70°C, stir mechanically (3000r / min), and dropwise add deionized water until the viscosity of the system suddenly decreases. At this time, the system has a phase inversion phenomenon, from water-in-oil (W / O) to oil-in-water (O / W). Continue to add deionized water and water-based environment Oxygen emulsion.

[0033] Test items

[0034] It can be seen from the relevant data that the emulsifier of the present invention has a small particle size of the emulsified E-21 epoxy emulsion and strong stability. The emulsifier contains a double epoxy group that can react with the curing agent. Improve and enhance the salt spray resistance and secondary adhesion of the paint film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com