A method for treating organic wastewater using a spray-type three-dimensional electrolysis device

A three-dimensional electrolysis, organic wastewater technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of low current efficiency, poor treatment effect, high energy consumption, etc. The effect of enhanced wastewater treatment capacity and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Spray type three-dimensional electrolysis device

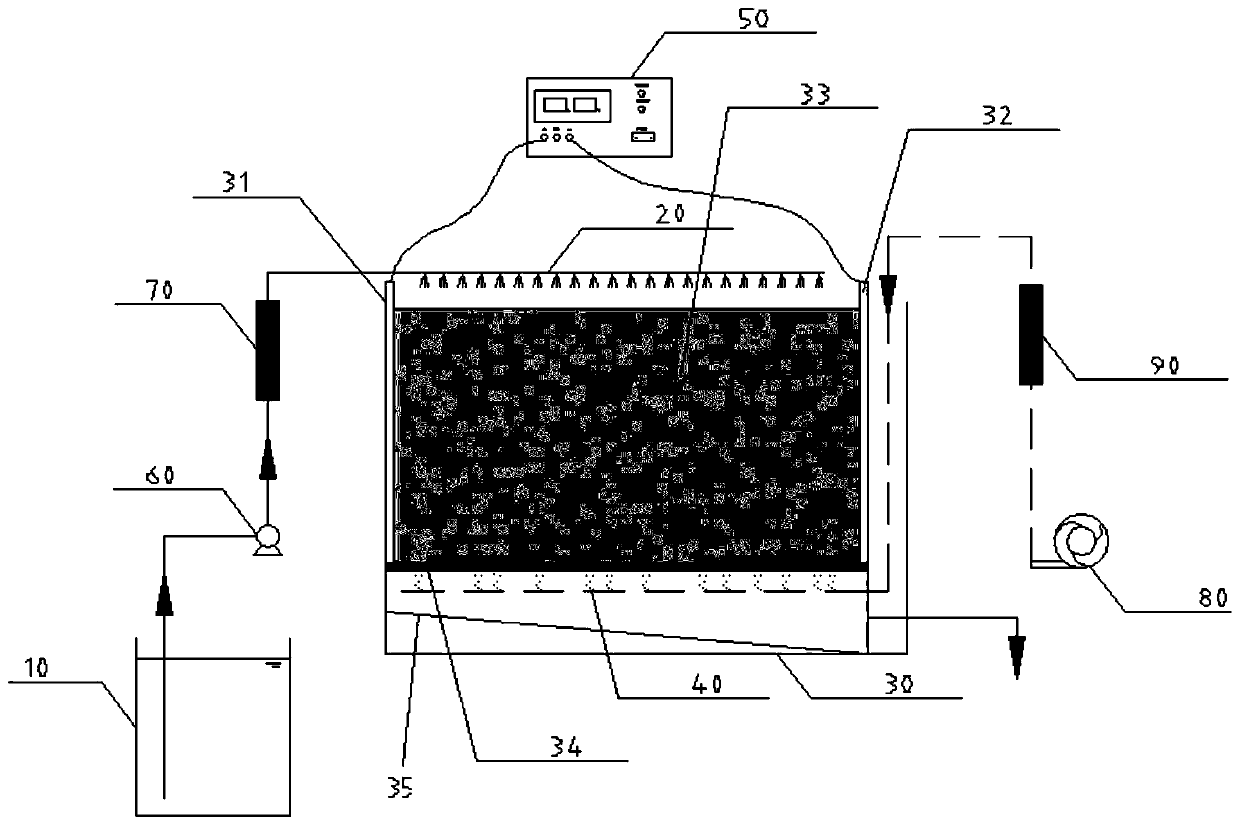

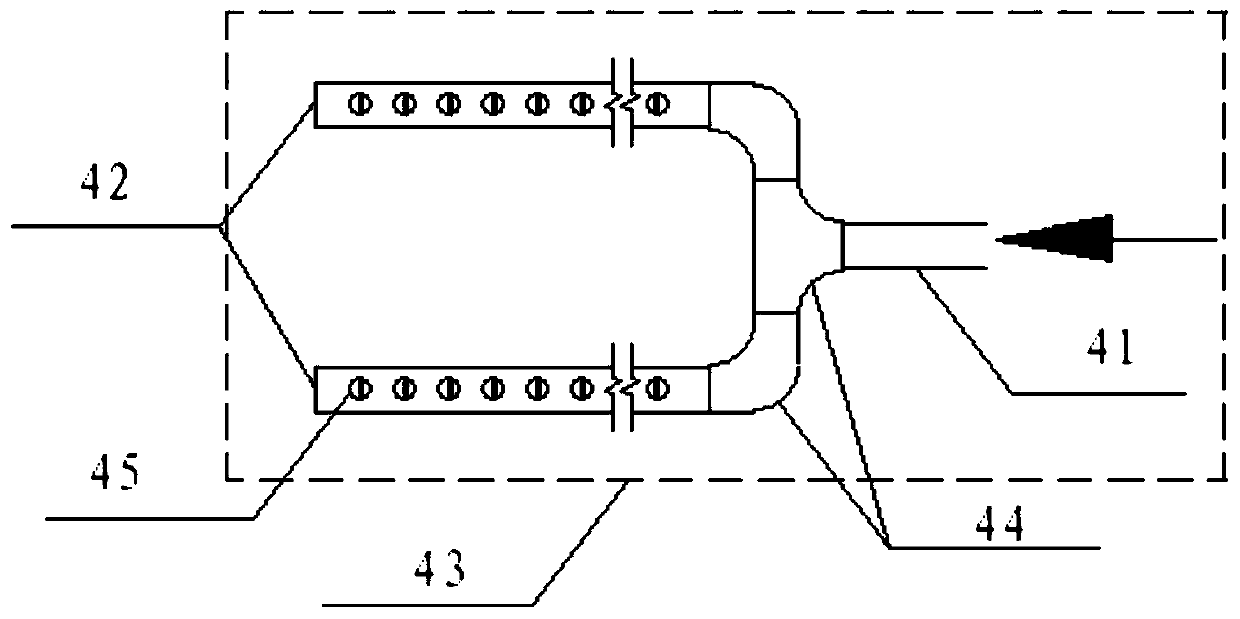

[0027] The structure reference of the spray type three-dimensional electrolysis device of the present invention figure 1 , including a water storage tank 10, a water distribution system 20, an electrolytic cell 30 and an air distribution system 40, the water distribution system 20 is arranged on the top of the electrolytic cell 30, the waste water in the water storage tank 10 enters the water distribution system 20 through a pipeline, and the The gas distribution system 40 is arranged at the lower part of the electrolytic cell 30 . Described electrolyzer also comprises the direct current voltage stabilized power supply 50 that provides power supply for electrolyzer 30, and described electrolyzer 30 is rectangular, is provided with plate type positive and negative collector electrode 31,32 at electrolyzer 30 two ends, plate type positive, negative. The negative collectors 31, 32 are respectively connected ...

Embodiment 2

[0029] Embodiment 2: method for treating organic wastewater by spray electrolysis device

[0030] First start the water inlet pump, spray the wastewater in the water storage tank into the electrolytic cell, wet the particle electrode layer, wait until the water level of the electrolytic cell rises to the particle electrode, open the drain valve, and discharge the water back to the water storage tank. Turn on the blower, adjust the air volume, keep the particle electrode slightly turned, turn on the DC stabilized power supply, and perform electrolysis in constant voltage mode. According to the wastewater treatment time determined in the pre-test, adjust the flow rate of the water inlet pump to achieve continuous treatment.

[0031] (1) Distribute air to the electrolytic cell through the air distribution system, so that the air evenly passes through the particle electrode from bottom to top to make the particle electrode fluffy, and the volume ratio of the air volume per hour to ...

Embodiment 3

[0034] Embodiment 3: Treatment of brown copper waste liquid in circuit board factory

[0035]The spray type three-dimensional electrolysis device in the embodiment 1 is used to process the copper browning waste liquid of the circuit board factory. The flat plate positive and negative collectors 31 and 32 adopt the titanium mesh loaded with ruthenium iridium oxide coating, and the activated carbon particles are the particle electrodes. The filling height of the particle electrode is 550 mm, and the flat positive and negative collectors 31 and 32 are 600 mm high, 60 mm wide and 10 mm thick. The COD of brown copper waste liquid is 10500mg / L, the sulfuric acid content is 5%, the copper ion concentration is 30g / L, and the conductivity is >100ms / cm. When using a spray electrolysis device, a voltage of 100V is applied between the flat electrodes, the ratio of air flow per hour to the volume of the particle electrode is 5:1, the ratio of water inflow to the particle electrode per hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com