Stamping die for manufacture of automobile roofs

A technology for automobile roof and stamping die, which is applied in the field of stamping dies and stamping dies for automobile roof manufacturing and production, can solve the problems of inconvenient replacement, poor thermal conductivity, and cannot be used in combination, and achieves convenient disassembly, prevention of mold damage, and stable installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

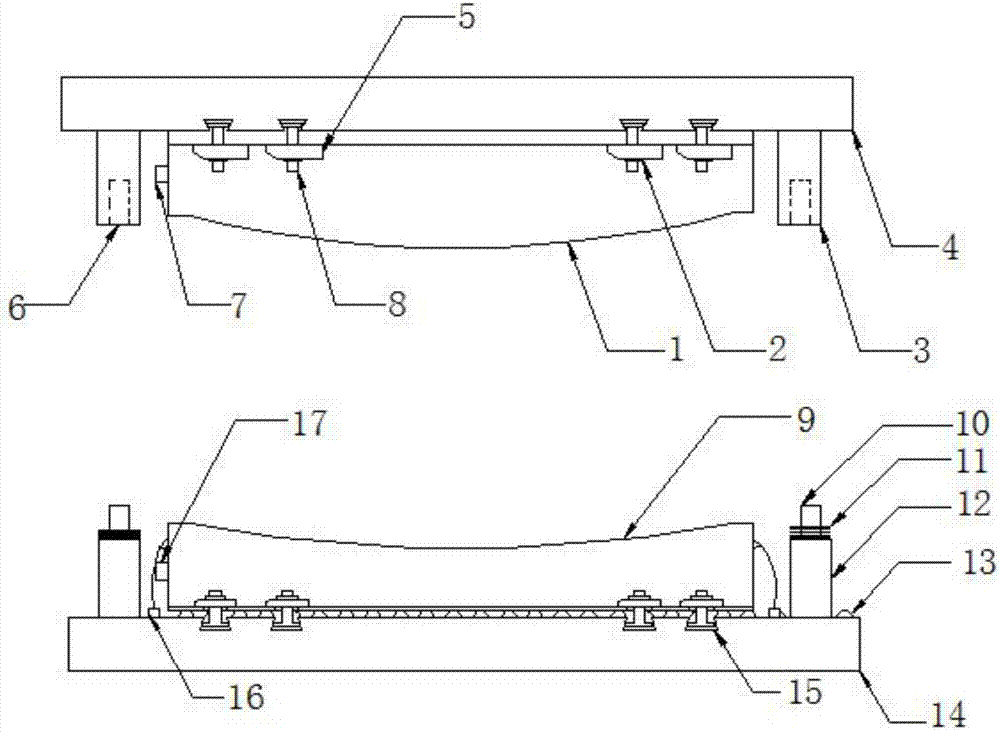

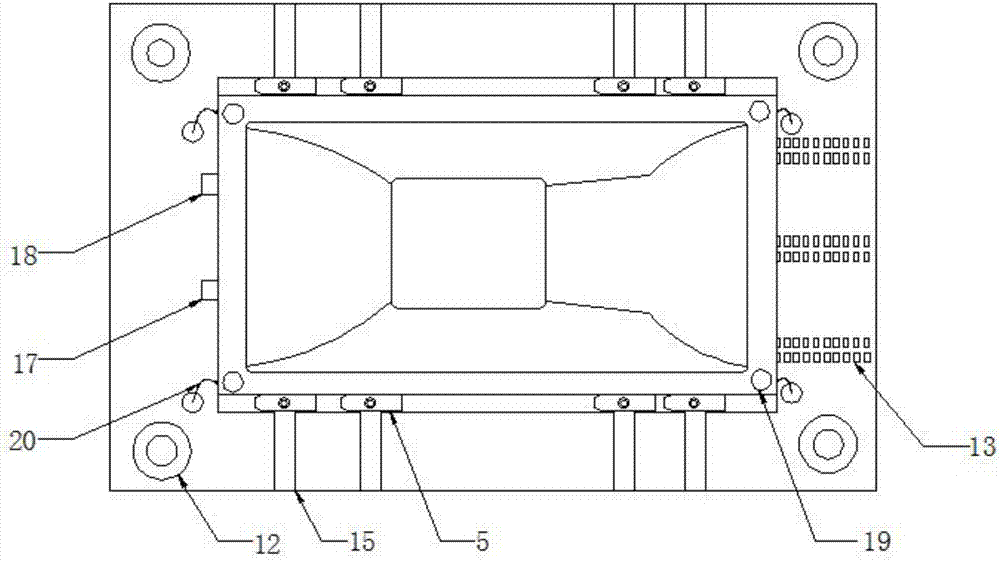

[0016] Such as Figure 1-2 As shown, a stamping die for the production of automobile ceilings includes an upper mold 1, an upper mold fixing plate 4, a lower mold 9 and a lower mold fixing plate 14, and the upper mold fixing plate 4 and the lower mold fixing plate 14 are provided with a card slot 15, and the upper support shaft 3 is installed on the upper mold fixing plate 4, the upper mold 1 is installed on the upper shaft fixing plate 4 through the threaded shaft 8, the spacer 5 and the bolt 2, and the upper mold 1 side is provided with an upper mold oil inlet port 7, the lower mold 9 is installed on the lower shaft fixing plate 14 through the threaded shaft 8, the cushion block 5 and the bolt 2, and the lower mold oil inlet 17 and the lower mold oil outlet 18 are installed on the side of the lower mold 9, and the lower mold The 9 four corners are provided with grooves 19, iron chains 20 and iron blocks 16, the lower support shaft 12 is installed on the lower mold fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com