Bagasse carbonized ruthenium-loaded biomass-based catalyst as well as preparation method and application thereof

A biomass and catalyst technology, which is applied to the field of bagasse carbonization-supported ruthenium biomass-based catalyst and its preparation, can solve the problems of poor catalyst stability and loss, and achieve the effects of good stability, reduced loss, and a simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation of bagasse carbonization supported ruthenium biomass-based catalyst, the steps are as follows:

[0044] 1. Bagasse pretreatment:

[0045] After the bagasse is dried in the sun, it is pulverized by a pulverizer, and the 150-180um part is taken, and dried in a vacuum drying oven at 60°C for 12h; the dried bagasse powder is washed with toluene-ethanol (2:1, v / v) in a 500ml Soxhlet extractor. ) at 140° C. for 6 hours to obtain dewaxed bagasse, which was dried in a vacuum oven at 60° C. for 16 hours for later use.

[0046] 2. Carbonization of bagasse:

[0047] Take 3g of pretreated bagasse and put it in the tube furnace, first pass nitrogen gas to check the air tightness of the whole pipeline and empty the air in the pipeline; then seal the whole pipeline, use nitrogen to purify the furnace tube, and control the nitrogen The flow rate was 70mL / min, the heating rate was 5°C / min, heated from room temperature to 450°C and kept at this temperature for 1.5h; after...

Embodiment 2

[0053] Preparation of bagasse-supported ruthenium biomass-based catalysts at different carbonization temperatures:

[0054] The carbonization temperature was changed during the carbonization of bagasse, and the other conditions were the same as in Example 1, wherein the carbonization temperatures were 300°C, 350°C, 400°C, 450°C, and 500°C, respectively.

Embodiment 3

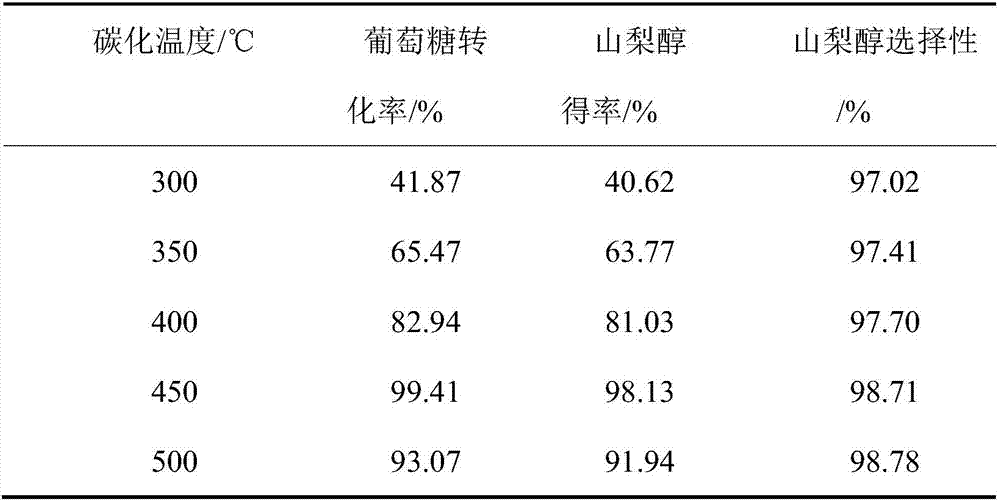

[0056] Utilize bagasse carbonization loaded ruthenium biomass-based catalysts under different carbonization temperatures prepared in Example 2 to catalyze the preparation of sorbitol from glucose:

[0057] 25ml of 10wt% glucose, 1wt% (relative to the content of the reaction system) Ru / CSB catalysts prepared under different carbonization temperatures in Example 2 were added to the stainless steel reactor, and after purging the reactor with hydrogen, the hydrogen pressure in the reactor was adjusted to 3Mpa, and then the reactor was heated to 120°C, and then the stirring was started at 600rpm, and the reaction time was 2 hours.

[0058] After the reaction, the reaction solution was detected by high performance liquid chromatography, and the conversion rate of glucose and the yield of sorbitol obtained are shown in Table 1.

[0059] Table 1 Catalytic effects of Ru / CSB catalysts at different carbonization temperatures

[0060]

[0061] As can be seen from Table 1, the carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com