Oxidized graphene carbon support film TEM grid and preparation method thereof

A graphene carbon, transmission electron microscope technology, applied in electrode system manufacturing, discharge tube/lamp manufacturing, circuits, etc., can solve the problems of samples failing to meet contrast requirements, complicated carbon support film preparation process, and low mechanical strength. , to achieve the effect of simple steps, simple preparation process and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A graphene oxide carbon support film transmission electron microscope grid and its preparation method, its steps are as follows: (1) get a piece of common carbon-free membrane electron microscope grid and put it on the filter paper; (2) evenly spread the graphene oxide solution on the (3) volatilize the solvent at normal temperature or under heating conditions.

[0019] The invention provides a method for preparing an ultra-thin carbon film with high mechanical strength, high sample adhesion and high contrast.

Embodiment 1

[0022] (1) Get the 1000-mesh transmission electron microscope copper carrier grid without supporting film and put it on the filter paper;

[0023] (2) Use a pipette gun to pipette the concentration to 0.1mg·mL -1 5 μL of graphene oxide aqueous solution was dropped naturally on the surface of the copper mesh;

[0024] (3) Place the above-mentioned whole sample in a clean and dust-free room temperature environment until the water evaporates naturally.

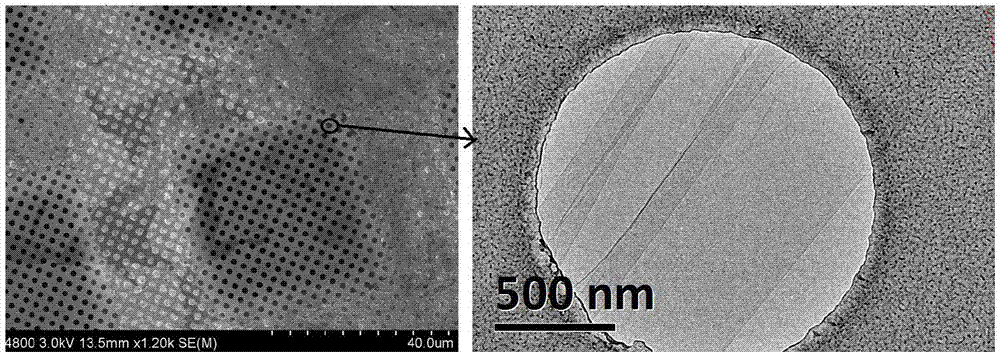

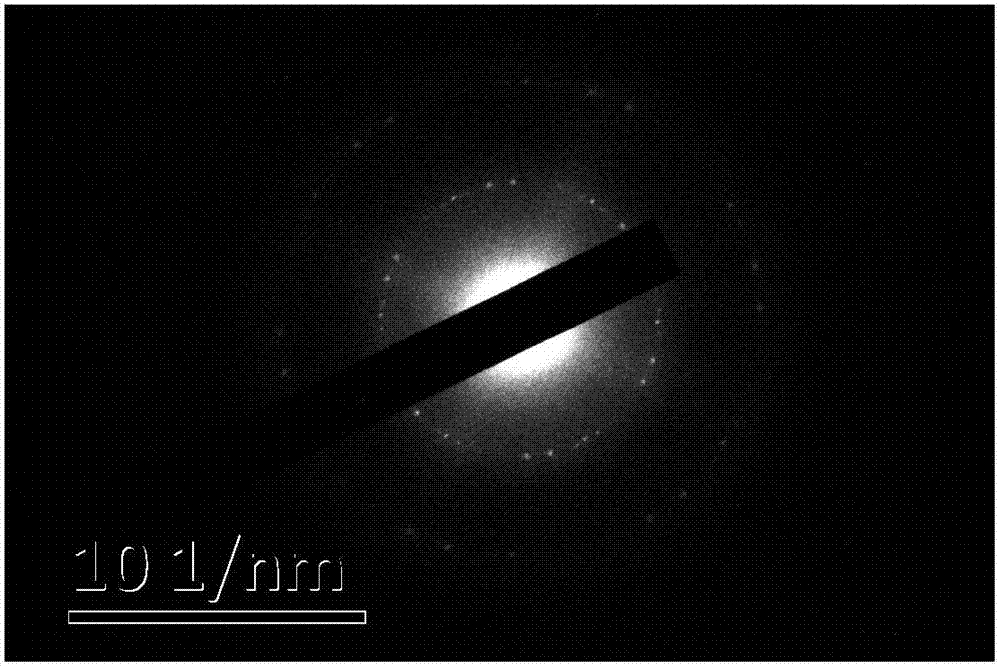

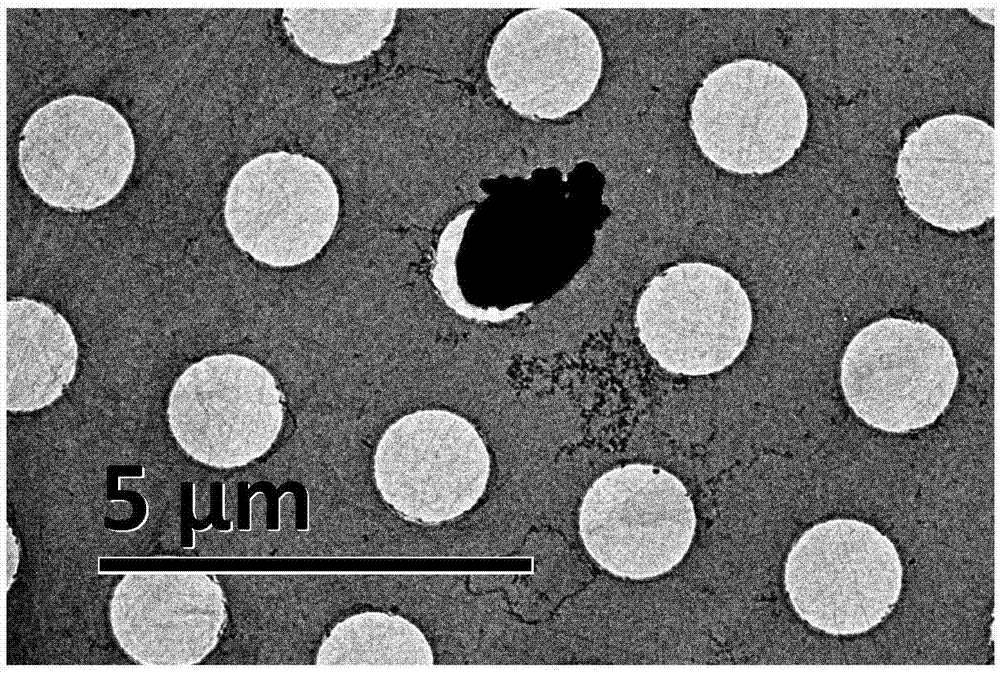

[0025] Depend on figure 1 It can be seen that the graphene sheets are tiled on the hollow holes, figure 2 It can be seen from the electron diffraction pattern that only three layers of graphene are formed at the thickest part. The carrier grid is used for the sample preparation of nano-silicon particles, such as image 3 shown in image 3 It can be seen from the figure that the strength of the graphene support film is high, and the integrity of the support film is still maintained after the nano-silicon particles are loaded...

Embodiment 2

[0027] (1) Take a 200-mesh transmission electron microscope grid with a microgrid support film, and immerse it at a concentration of 0.5 mg·mL -1 The graphene oxide ethanol solution is evenly pulled up at a speed of 1mm / min;

[0028] (2) Heat the above sample in a clean and dust-free oven at 40°C until the water evaporates naturally. Through testing, the graphene support film has high strength and high contrast.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com