Calculation method for equivalent torsional, tensile and flexural stiffness of ball screw

A technology of bending stiffness and tensile stiffness, which is used in calculations, design optimization/simulation, special data processing applications, etc., can solve the deviation of calculation results, and does not mention the calculation method of screw torsion and bending stiffness, etc. problem, to achieve the effect of accurate results and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to calculate the equivalent stiffness of the lead screw, the steps of the calculation scheme provided by the present invention are:

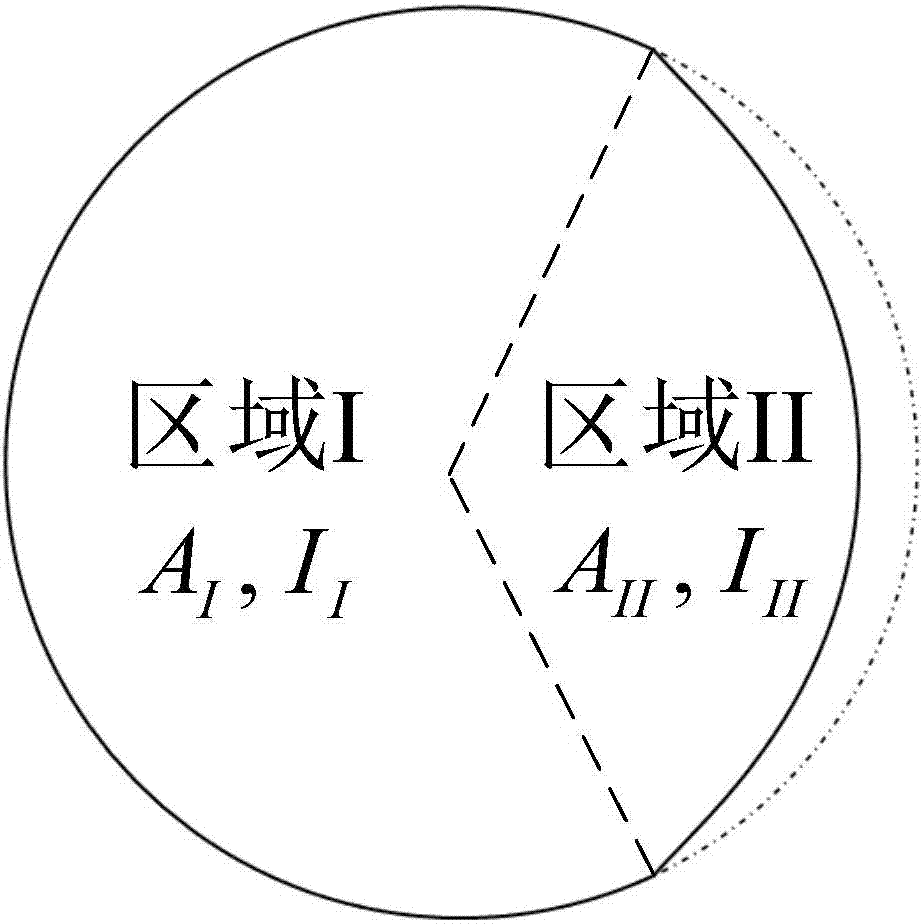

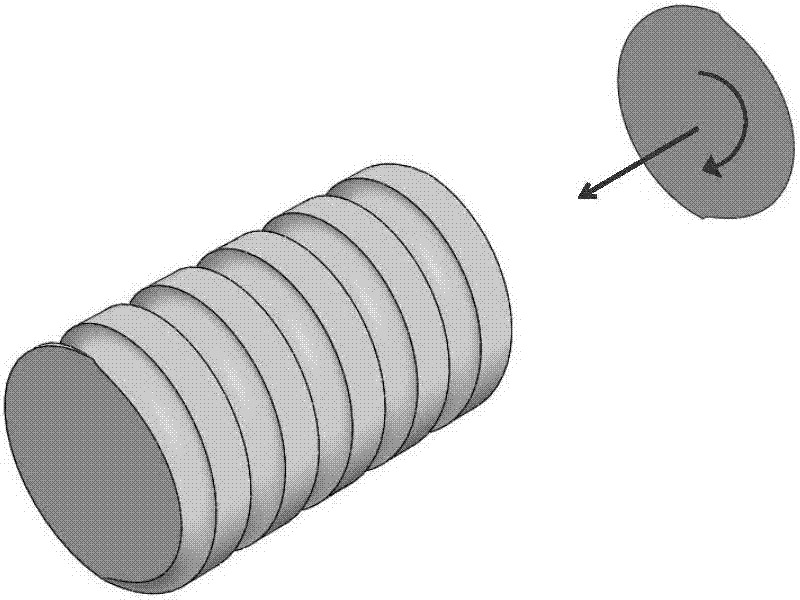

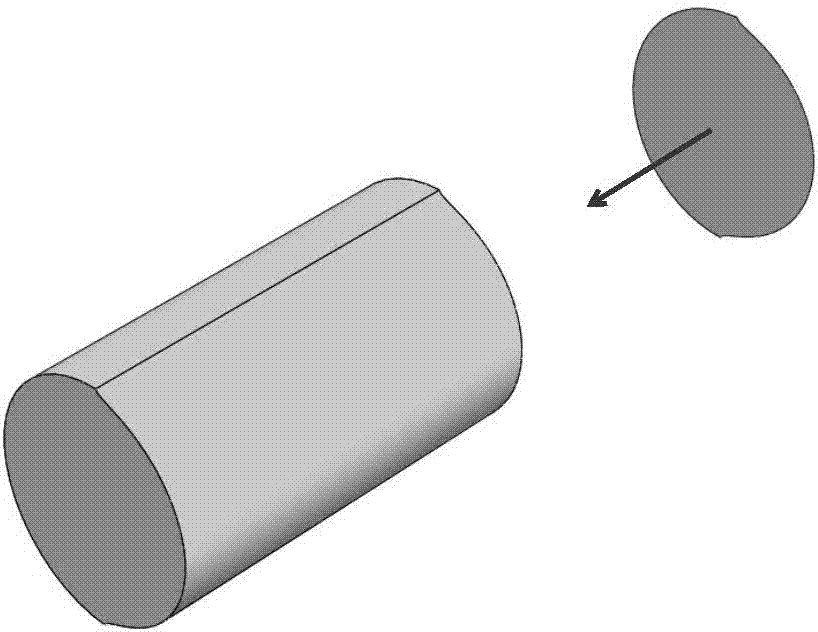

[0052] 1) Investigate the cross-section of the lead screw when the number of lines is 1, such as figure 1 The cross-sectional view of the single-wire lead screw shown, divides the cross-section into two surfaces of area I and area II according to the fan shape and the crescent shape, such as figure 2 and image 3 The single wire ball screw diagram shown and the figure 2For the constant-section beam diagram with the same cross-section, calculate the torsional and tensile stiffness of the constant-section beam with the same cross-section as that of the single-wire ball screw (the cross-section is perpendicular to the axis of the screw):

[0053]

[0054] where G(I ρ ) is the torsional stiffness of the beam with equal section, E(A) is the tensile stiffness of the beam with equal section, G is the shear modulus of the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com