Angelica anomala polysaccharide extracted on basis of response surface optimization and preparation method and application thereof

A response surface methodology, the technology of Sichuan Angelica, applied in the field of biomedicine, can solve the problems of changing the biological activity of polysaccharides, reducing the activity of natural polysaccharides, and reducing the size of polysaccharides, and achieves good bacteriostatic activity, reduced starch content, and increased sugar content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

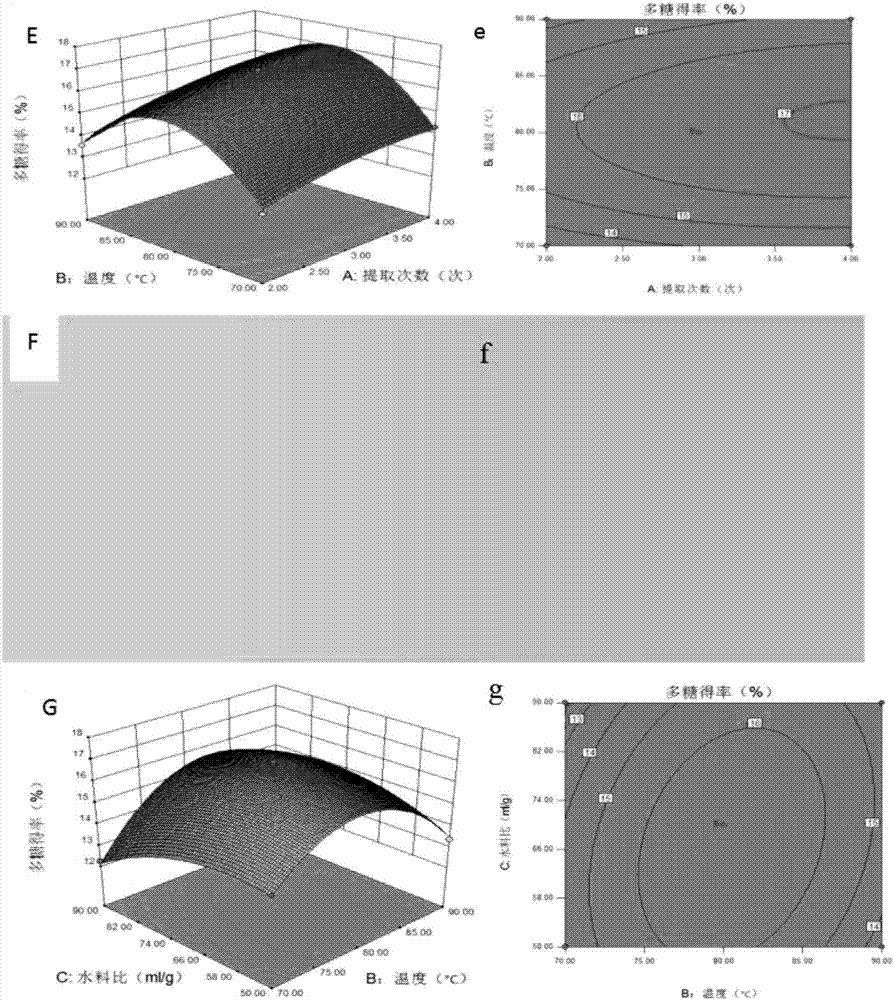

[0050] Investigation on optimization of hot water extraction polysaccharides from Angelica dahurica by response surface methodology

[0051] Based on the single factor experiment, the Box-Behnken method of Design-expert 8.0.7.1Trail software was used to design the experiment, and the polysaccharide yield of Radix Angelica dahurica was used as the response value to obtain the optimal extraction conditions.

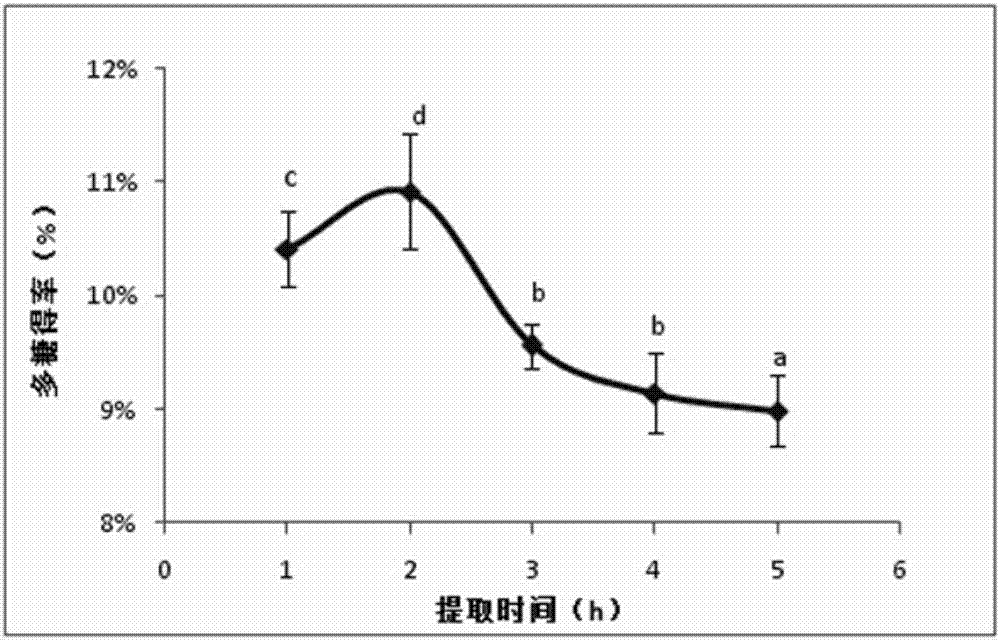

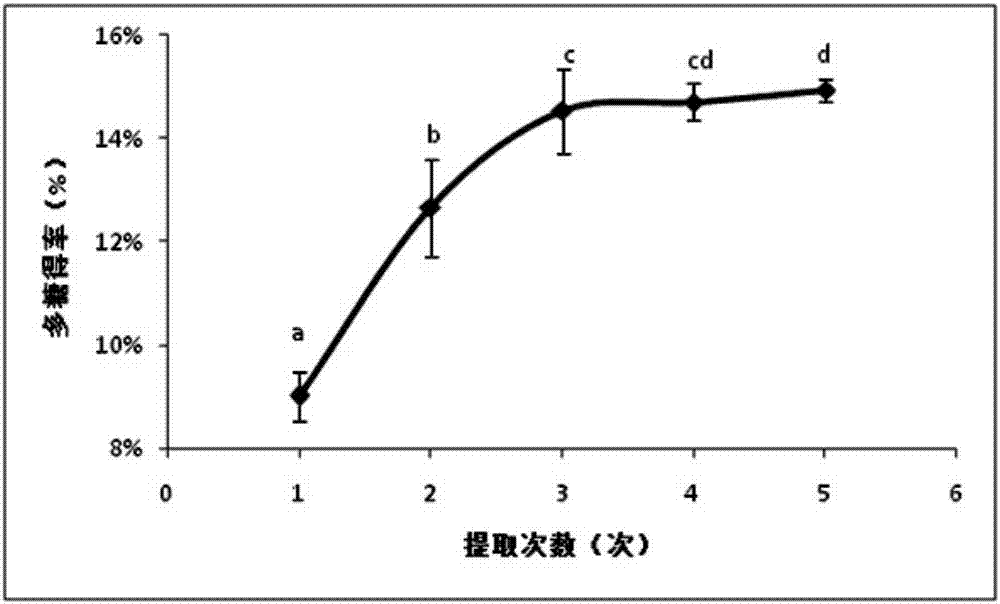

[0052] 1. Single factor test

[0053] Take the root of Baizhi root, wash it, dry it at 40°C, and crush it through a 40-mesh sieve. Weigh the powder sample of Angelica dahurica, add petroleum ether at 55°C to reflux for 4 hours, dry at 40°C, then add 80% ethanol to extract at 80°C for 4 hours to remove part of the pigment and oligosaccharides, evaporate the ethanol to dry, pulverize, and dry at 45°C Dry and set aside. The consumption of sherwood oil is calculated as 3mL by every gram of Chuan Baizhi powder, and the consumption of 80% ethanol is calculated as 2mL per gram o...

Embodiment 2

[0085] Preparation of Polysaccharides from Radix Angelica dahurica

[0086] The preparation method of Radix Angelica dahurica polysaccharide comprises the following steps:

[0087] A: degreasing and decolorization

[0088] Take the root of Baizhi root, wash it, dry it at 45°C, and crush it through a 40-mesh sieve. Weigh the powder sample of Angelica dahurica, add petroleum ether at 55°C to reflux for 4 hours, dry at 45°C, then add 80% ethanol to extract at 80°C for 4 hours to remove part of the pigment and oligosaccharides, evaporate the ethanol to dry, pulverize, and dry at 45°C Dry and set aside. The consumption of described sherwood oil is calculated as 3mL by every gram of Chuan Baizhi powder, and the consumption of 80% ethanol is calculated as 2mL by every gram of Chuan Baizhi powder.

[0089] B: extract

[0090] The powder after degreasing and depigmentation was extracted with water at 81°C for 3 times, each time for 1 hour, the ratio of water to Baizhi powder was 68...

Embodiment 3

[0104] Preparation of Polysaccharides from Radix Angelica dahurica

[0105] Compared with Example 2 in this example, the drying temperature in step A is 50°C, and 4 times the amount of petroleum ether of Angelica dahurica is added to heat and reflux for degreasing;

[0106] In step C, slowly add absolute ethanol to the concentrated solution until the final concentration of ethanol in the mixed solution is 70%, place it at 6°C for 24 hours, centrifuge to obtain the precipitation of the polysaccharide of Angelica dahurica dahurica, and discard the supernatant. Redissolve the polysaccharide precipitate of Baizhi Baizhi with water, centrifuge at 4000r / min for 10min to remove impurities, and add ethanol to the supernatant to reach a concentration of 70%. After standing at 6°C for 24 hours, centrifuge for the third time, and take the precipitate after the third centrifugation for future use;

[0107] All the other conditions are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com