Method for synthesizing cobalt oxide and ferrocobalt layered bimetal hydroxide compound

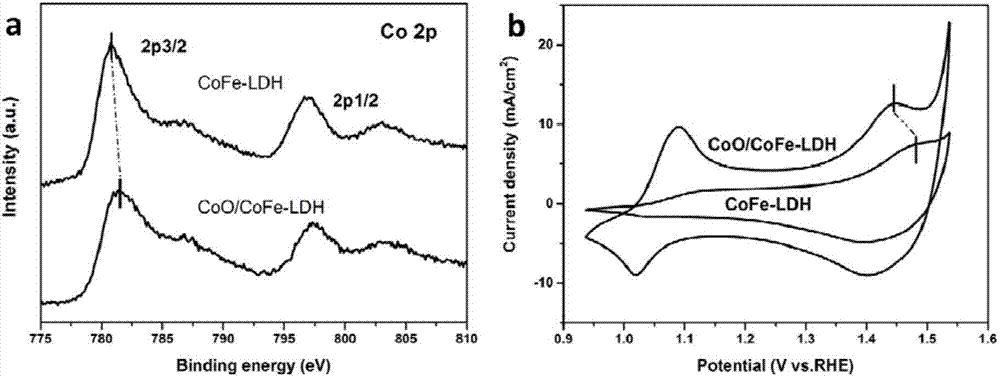

A layered bimetallic, hydroxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high catalyst cost and poor reusability of layered bimetallic hydroxides, achieve lower binding energy, excellent Water oxidizing performance, effect of reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

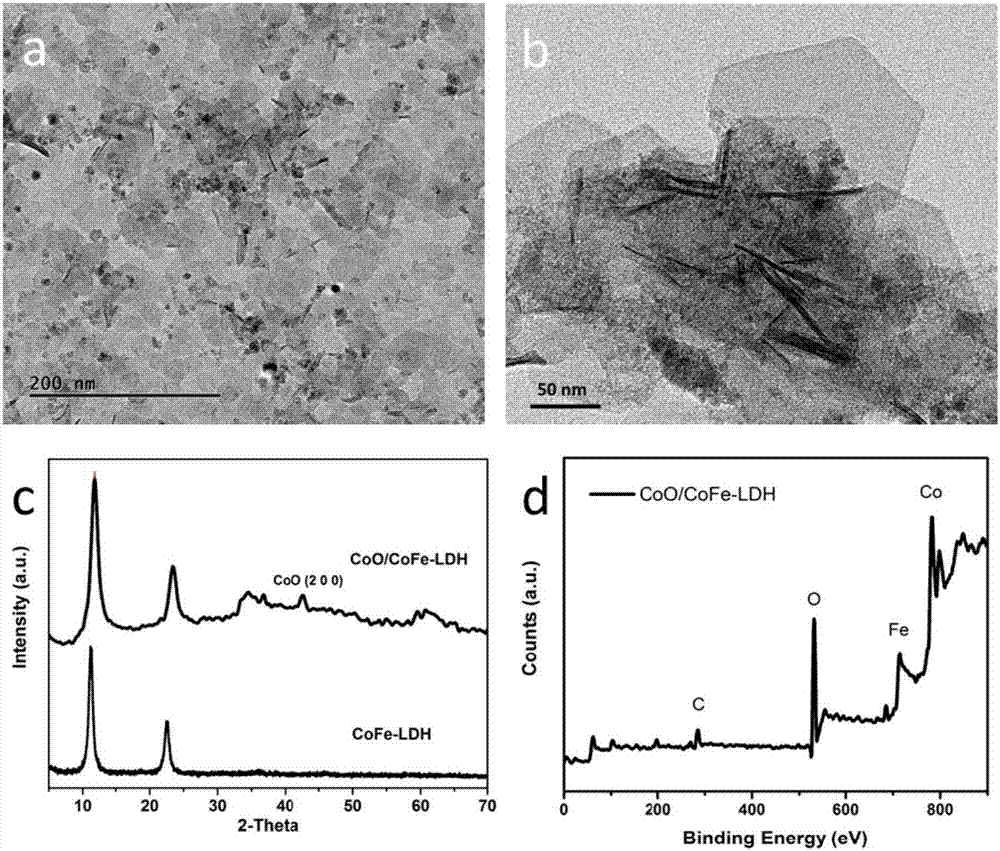

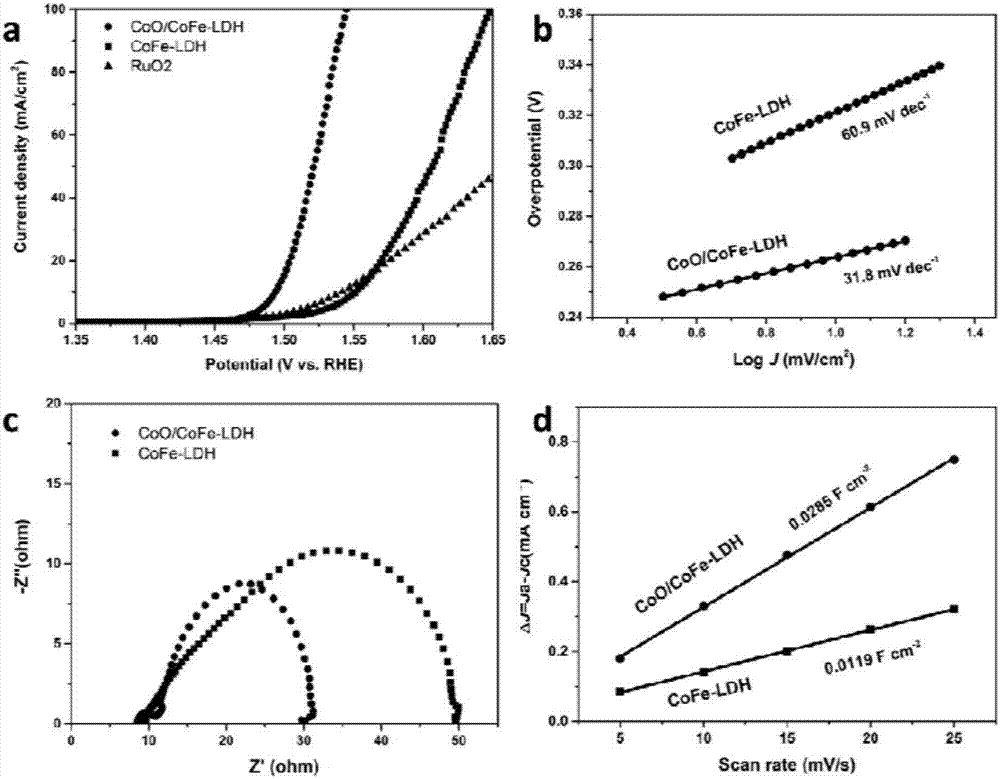

[0025] This embodiment provides a method for synthesizing a cobaltous oxide and cobalt-iron layered double hydroxide composite by nanosecond laser ablation in the liquid phase, comprising the following steps:

[0026] (1) Using the bulk cobalt-iron alloy target as the raw material, the surface of the alloy target was polished with sandpaper and then ultrasonically cleaned with dilute hydrochloric acid to remove the oxide layer; then the surface of the alloy target was cleaned several times with deionized water to remove residual dilute hydrochloric acid, and then Dry the surface of the alloy target for use. Among them, the purity of the bulk cobalt-iron alloy target is 99.9%.

[0027] (2) Place the dried alloy target in an 80 ml beaker, and add 40 ml of 1 mol / L sodium chloride solution into the beaker to make the liquid level above the alloy target 3-4 cm.

[0028] (3) Start the nanosecond laser, adopt the nanosecond pulse laser with a wavelength of 1064 nanometers to ablate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com