Vanadium-titanium iron ore utilization method

A vanadium ilmenite and pretreatment technology, applied in the field of metallurgy, can solve the problems of poor economy, difficulty in wide-scale promotion, waste of titanium resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

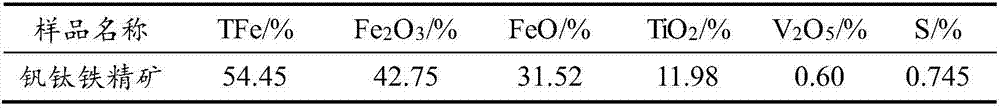

[0035] Using vanadium-titanium iron concentrate as raw material, the main components and mass percentage of vanadium-titanium-iron concentrate are shown in Table 1, and the particle size distribution of the vanadium-titanium-iron concentrate is shown in Table 2, and Table 1 shows the The main components and content of the concentrate, Table 2 is the particle size distribution of a certain vanadium-titanium iron concentrate:

[0036] Table 1 The main components and content of a vanadium-titanium iron ore concentrate

[0037]

[0038]Note: TFe is the total mass percentage of iron elements in the sample.

[0039] Table 2 Particle size distribution of a vanadium-titanium iron ore concentrate

[0040]

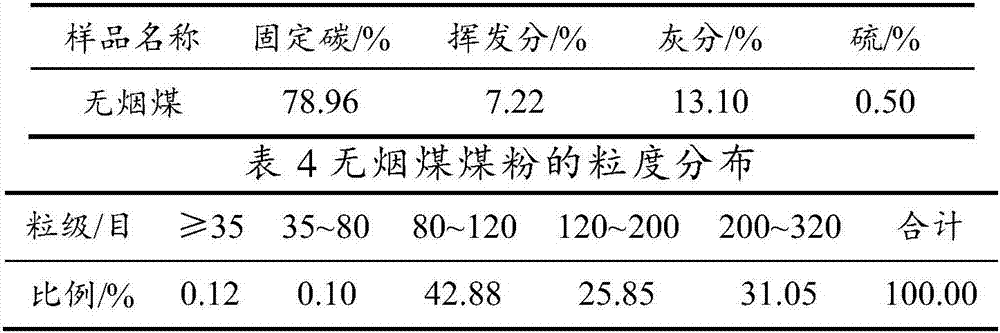

[0041] The reducing agent is anthracite coal powder. The main chemical composition content and particle size distribution of anthracite coal powder are shown in Table 3 and Table 4 respectively. Table 3 shows the main components and content of anthracite coal powder, and Tabl...

Embodiment 2

[0054] Using vanadium-titanium iron concentrate as raw material, the main components and mass percentage of vanadium-titanium-iron concentrate are shown in Table 1, and the particle size distribution of the vanadium-titanium-iron concentrate is shown in Table 2.

[0055] Anthracite coal powder was used as the reducing agent, and the main chemical composition content and particle size distribution of the anthracite coal powder are shown in Table 3 and Table 4, respectively.

[0056] (1) Roasting pre-oxidation of vanadium-titanium iron concentrate

[0057] The above-mentioned vanadium-titanium iron concentrate was oxidized and roasted at 1000°C for 1.0 h to obtain a pretreated product. The content of FeO in the vanadium-titanium iron concentrate after oxidation and roasting was 1.04%, and the S content was 0.083%. The removal rate is 88.47%;

[0058] (2) Blocking of mixed materials

[0059] The pretreatment product is proportioned with anthracite coal powder and bentonite and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com