Low-temperature superoxide dismutase protecting agent and preparation method thereof

A superoxide and dismutase technology, applied in the field of bioengineering, can solve the problems of loss of SOD enzyme activity, high production cost, restricting the industrial application of superoxide dismutase, etc., and achieves the effect of maintaining enzyme activity and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

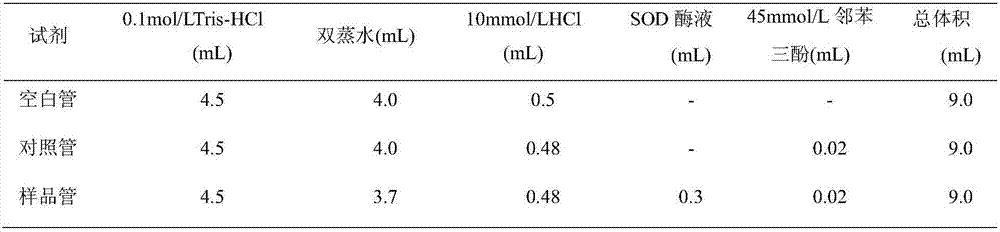

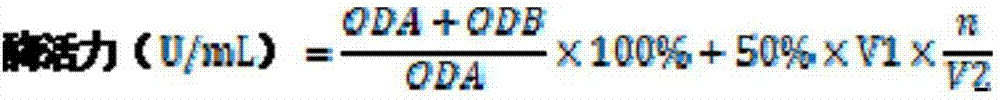

Method used

Image

Examples

Embodiment 1

[0033] A low-temperature superoxide dismutase protective agent, comprising the following raw materials in parts by weight, low-temperature superoxide dismutase 300mL, polyethylene glycol 100g, sodium hyaluronate 11g, DTT 2g, imidazolidinyl urea 1g, trehalose 5g, 122g of deionized water.

[0034] The preparation method of described low-temperature superoxide dismutase is:

[0035] (1) Preparation of crude enzyme solution: Aseptic operation, inoculate the activated Pseudomonas marinosa into the liquid fermentation medium, ferment at 20°C, 160r / min for 48h, and ferment the bacteria liquid at 4°C, 6 Centrifuge at 000r / min for 30min to obtain wet cells, centrifuge at 6000r / min for 30min at 4°C, dissolve the wet cells in phosphate buffer, and crush them in a 480W ultrasonic ice bath for 30min (crushing for 5s with an interval of 5s). After crushing, 4 Centrifuge at 12 000r / min for 15min, and the supernatant is the crude enzyme solution. The formula percentage of the above liquid fe...

Embodiment 2

[0045] A low-temperature superoxide dismutase protective agent, comprising the following raw materials in parts by weight, low-temperature superoxide dismutase 400mL, polyethylene glycol 200g, sodium hyaluronate 30g, DTT 4g, imidazolidinyl urea 2g, trehalose 10g, deionized water 312g.

[0046] The preparation method of the low-temperature superoxide dismutase is the same as in Example 1.

[0047] The preparation method of described low-temperature superoxide dismutase protective agent, comprises the following steps:

[0048] (1) Trehalose and polyethylene glycol were added to deionized water, stirred evenly, and subjected to high-temperature moist heat sterilization. During sterilization, the temperature was controlled at 120°C, and sterilized at this temperature for 25 minutes to obtain the base liquid;

[0049] (2) Add sodium hyaluronate and DTT to low-temperature superoxide dismutase, and stir evenly, then use a filter to filter and sterilize the mixed solution of low-temp...

Embodiment 3

[0052] A low-temperature superoxide dismutase protective agent, comprising the following raw materials in parts by weight, low-temperature superoxide dismutase 500mL, polyethylene glycol 300g, sodium hyaluronate 54g, DTT 6g, imidazolidinyl urea 3g, trehalose 15g, 582g of deionized water.

[0053] The preparation method of the low-temperature superoxide dismutase is the same as in Example 1.

[0054] The preparation method of described low-temperature superoxide dismutase protective agent, comprises the following steps:

[0055] (1) Trehalose and polyethylene glycol were added to deionized water, stirred evenly, and subjected to high-temperature moist heat sterilization. During sterilization, the temperature was controlled at 125°C, and sterilized at this temperature for 30 minutes to obtain the base liquid;

[0056] (2) Add sodium hyaluronate and DTT to low-temperature superoxide dismutase, and stir evenly, then use a filter to filter and sterilize the mixed solution of low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com