Functional PE water supply pipe formula and preparation method thereof

A water supply pipe and functional technology, applied in the development and application of polymer materials, can solve the problems of hidden dangers to health and safety, no antibacterial effect, bacterial growth, etc., and achieve the effects of increasing the finish, improving processing performance, and reducing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

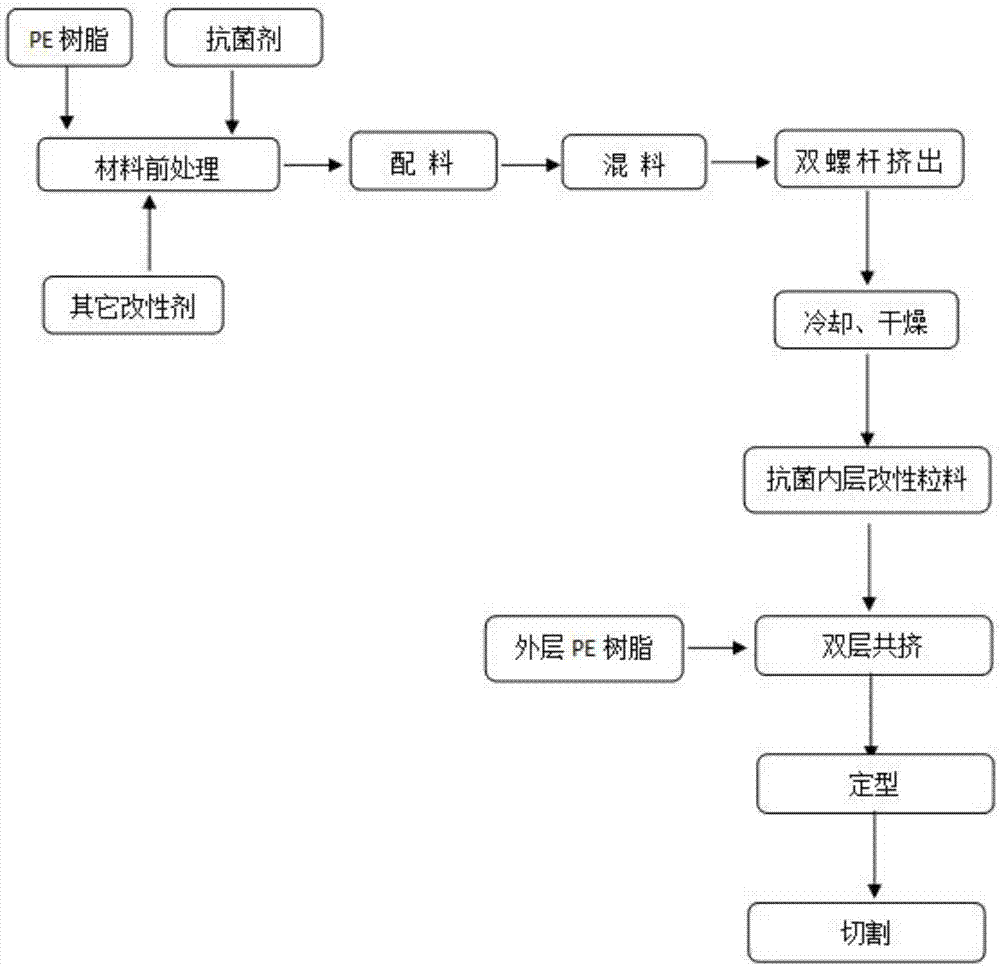

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of functional PE water supply pipe of the present invention, comprises the following steps:

[0030] a. Dry the inner layer formula material to control the water content below 0.1%;

[0031] b. According to the inner layer design formula measurement, the formula composition is as follows:

[0032] Sinopec PEYEM-4902T: 100 copies;

[0033] Antiseptic and antibacterial agent: 0.2 parts;

[0034] Antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.2 parts;

[0035] Lubricant (N, N'-ethylene bis stearamide): 0.5 parts;

[0036] Wherein, the antiseptic and antibacterial agent is a self-made nano antiseptic and antibacterial agent, using ion exchange method, using silicon carbide nanomaterials as a carrier, and introducing inorganic antibacterial silver ions;

[0037] c. Put all the inner layer formula materials into a high-speed mixer and stir and mix, and the temperature is controlled at 75°C;

[0038] d. The material...

Embodiment 2

[0041] A kind of preparation method of functional PE water supply pipe of the present invention, comprises the following steps:

[0042] a. Dry the inner layer formula material to control the water content below 0.1%;

[0043] b. According to the inner layer design formula measurement, the formula composition is as follows:

[0044] Sinopec PEYEM-4902T: 100 copies;

[0045] Antiseptic and antibacterial agent: 0.5 parts;

[0046] Antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.5 parts;

[0047] Lubricant (N, N'-ethylene bis stearamide): 1 part;

[0048] Wherein, the antiseptic and antibacterial agent is a self-made nano antiseptic and antibacterial agent, using ion exchange method, using silicon carbide nanomaterials as a carrier, and introducing inorganic antibacterial copper ions;

[0049] c. Put all the inner layer formula materials into a high-speed mixer and stir and mix, and the temperature is controlled at 75°C;

[0050] d. The materials m...

Embodiment 3

[0053] A kind of preparation method of functional PE water supply pipe of the present invention, comprises the following steps:

[0054] a. Dry the inner layer formula material to control the water content below 0.1%;

[0055] b. According to the inner layer design formula measurement, the formula composition is as follows:

[0056] Sinopec PEYEM-4902T: 100 copies;

[0057] Antiseptic and antibacterial agent: 1 part;

[0058] Antioxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate): 0.6 parts;

[0059] Lubricant (N, N'-ethylene bis stearamide): 1.5 parts;

[0060] Wherein, the anticorrosion and antibacterial agent is a self-made nano anticorrosion and antibacterial agent, using ion exchange method, using silicon carbide nanomaterials as a carrier, and introducing inorganic antibacterial zinc ions;

[0061] c. Put all the inner layer formula materials into a high-speed mixer and stir and mix, and the temperature is controlled at 75°C;

[0062] d. The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com