Calcium-zinc compound heat stabilizer

A heat stabilizer and calcium-zinc composite technology, which is applied in the field of calcium-zinc composite heat stabilizers, can solve the problems of high VOCs, strong odor, and low melting point, and achieve the effects of good environmental protection, easy production and operation, and low VOCs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

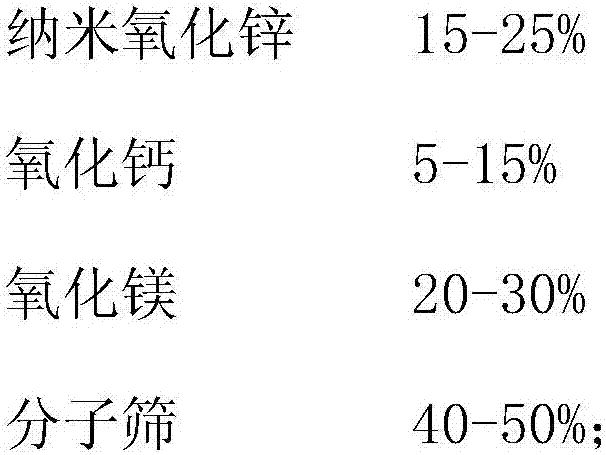

[0027] A kind of calcium-zinc composite heat stabilizer, the mass fraction of its formula is as follows:

[0028] Nano Zinc Oxide 20%

[0031] Molecular sieve 45%;

[0032] The preparation process is divided into automatic weighing section, mixing section and automatic packaging section. The automatic weighing section adopts automatic weighing and screw feeding system. The mixing section adopts double conical screw mixer with a mixing time of 30 minutes. The automatic packaging section adopts Fully automatic packaging machine, the entire production pipeline system is in a negative pressure sealed state.

[0033] The stirring speed in the mixing section is 60r / pm, and the stirring time is 30min.

[0034] The main contents of nano-zinc oxide, calcium oxide, magnesium oxide and molecular sieve are all ≥99%. Nano-zinc oxide is produced by indirect method. Molecular sieve is made of 4A molecular sieve and calcined at 800℃....

Embodiment 2

[0049] A kind of calcium-zinc composite heat stabilizer, the mass fraction of its formula is as follows:

[0050] Nano Zinc Oxide 18%

[0052] Magnesium Oxide 28%

[0053] Molecular sieve 42%;

[0054] The preparation process is divided into automatic weighing section, mixing section and automatic packaging section. The automatic weighing section adopts automatic weighing and screw feeding system. The mixing section adopts double conical screw mixer with a mixing time of 30 minutes. The automatic packaging section adopts Fully automatic packaging machine, the entire production pipeline system is in a negative pressure sealed state.

[0055] The stirring speed in the mixing section is 84r / pm, and the stirring time is 38min.

[0056] The main contents of nano-zinc oxide, calcium oxide, magnesium oxide and molecular sieve are all ≥99%. Nano-zinc oxide is produced by indirect method. Molecular sieve is made of 4A molecular sieve and calcined at 800℃....

Embodiment 3

[0058] A kind of calcium-zinc composite heat stabilizer, the mass fraction of its formula is as follows:

[0059] Nano Zinc Oxide 18

[0060] Calcium Oxide 12%

[0061] Magnesium Oxide 25%

[0062] Molecular sieve 45%;

[0063]The preparation process is divided into automatic weighing section, mixing section and automatic packaging section. The automatic weighing section adopts automatic weighing and screw feeding system. The mixing section adopts double conical screw mixer with a mixing time of 30 minutes. The automatic packaging section adopts Fully automatic packaging machine, the entire production pipeline system is in a negative pressure sealed state.

[0064] The stirring speed in the mixing section is 50r / pm, and the stirring time is 30min.

[0065] The main contents of nano-zinc oxide, calcium oxide, magnesium oxide and molecular sieve are all ≥99%. Nano-zinc oxide is produced by indirect method. Molecular sieve is made of 4A molecular sieve and calcined at 800℃. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com