Triple-return-stroke roller drying carbonizing machine

A drum drying and return-to-cycle technology, which is used in rotary carbonization furnaces, dehydration/drying/concentrated sludge treatment, direct heating and dry distillation, etc. The effect of energy efficiency and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

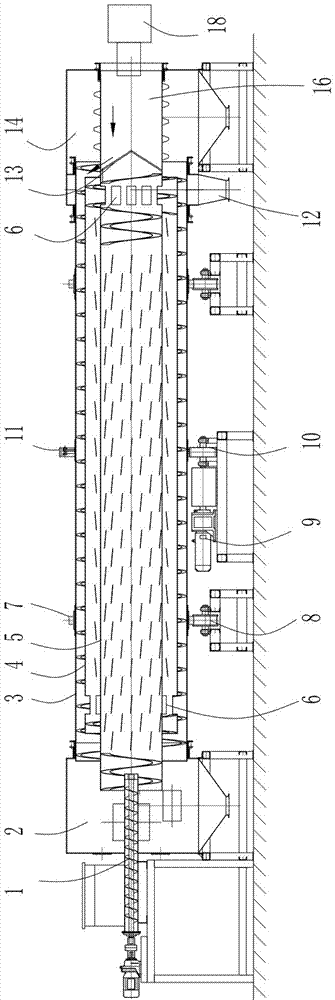

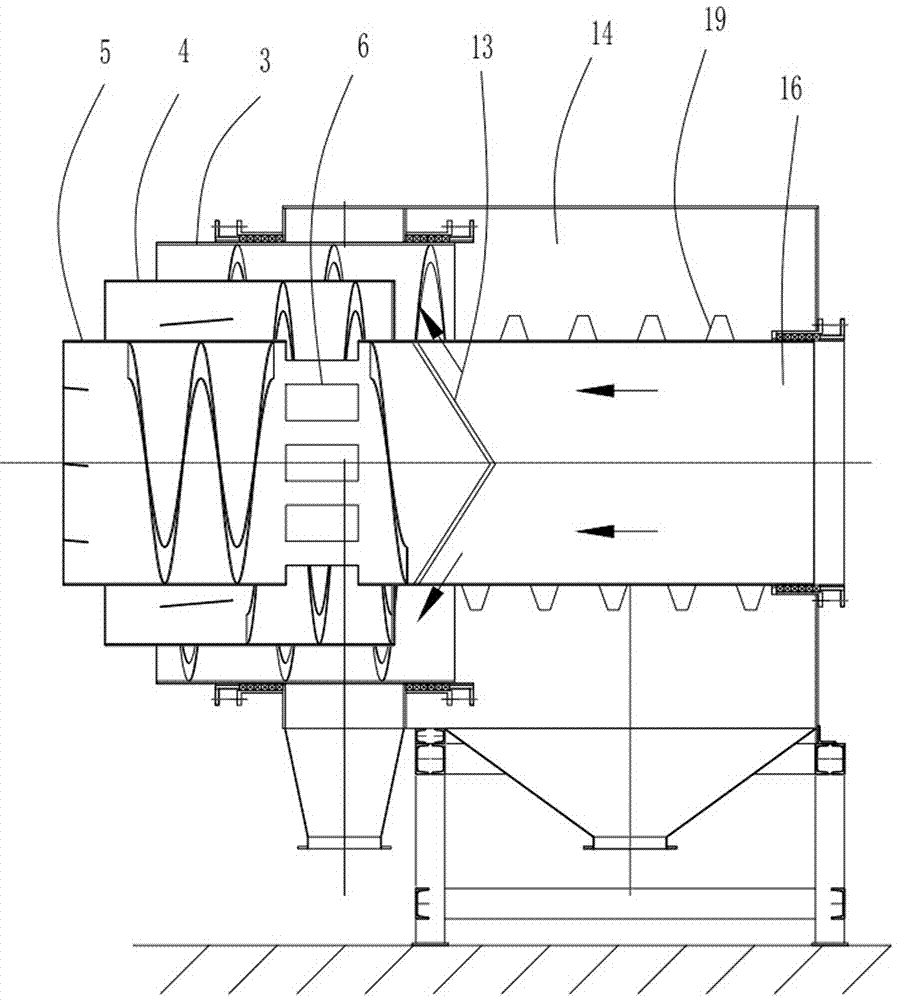

[0022] Embodiment 1: a kind of three-pass drum drying carbonization machine, such as figure 1 , 2 shown. The device includes an inner cylinder 5, a middle cylinder 4, and an outer cylinder 3 coaxially arranged and rotated synchronously, and the inner cylinder 5, the middle cylinder 4, and the outer cylinder 3 are nested in sequence, and the two ends of the outer cylinder form a rotational support. Such as figure 1 As shown, the left end of the urceolus is provided with an exhaust bin 2, the right end of the urceolus is provided with a carbonization bin 14, the left end of the urceolus is rotatably connected with the exhaust bin 2, and the right end of the urceolus is rotatably connected with the carbonization bin. The outer wall of the middle part of the urceolus is provided with a gear ring 11, and the bottom of the ring gear is provided with a gear 10 driven by a motor 9 as a power source for rotating the urceolus. The outer wall of the outer cylinder is respectively prov...

Embodiment 2

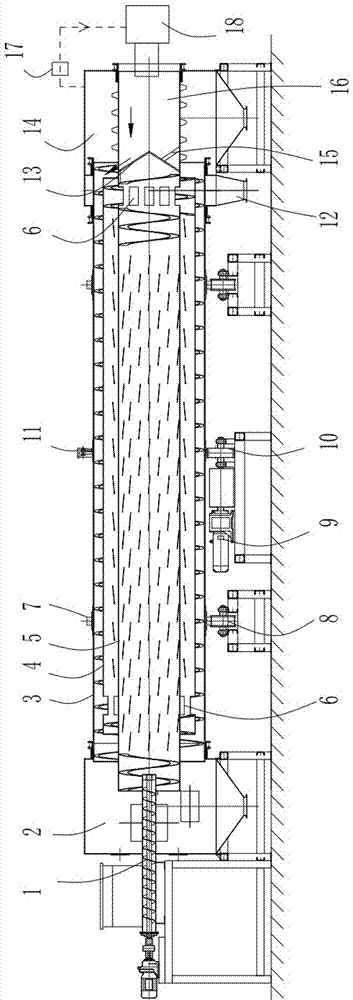

[0026] Embodiment 2: a kind of three-pass drum drying carbonization machine, such as image 3 , 4 shown. The device includes an inner cylinder 5, a middle cylinder 4, and an outer cylinder 3 coaxially arranged and rotated synchronously, and the inner cylinder 5, the middle cylinder 4, and the outer cylinder 3 are nested in sequence, and the two ends of the outer cylinder form a rotational support. Such as image 3 As shown, the left end of the urceolus is provided with an exhaust bin 2, the right end of the urceolus is provided with a carbonization bin 14, the left end of the urceolus is rotatably connected with the exhaust bin 2, and the right end of the urceolus is rotatably connected with the carbonization bin. The outer wall of the middle part of the urceolus is provided with a gear ring 11, and the bottom of the ring gear is provided with a gear 10 driven by a motor 9 as a power source for rotating the urceolus. The outer wall of the outer cylinder is respectively prov...

Embodiment 3

[0030] Embodiment 3: a kind of three-pass drum drying carbonization machine, such as Figure 5 shown. The device includes an inner cylinder 5, a middle cylinder 4, and an outer cylinder 3 coaxially arranged and rotated synchronously, and the inner cylinder 5, the middle cylinder 4, and the outer cylinder 3 are nested in sequence, and the two ends of the outer cylinder form a rotational support. The left end of the urceolus is provided with an exhaust bin 2, and the right end of the urceolus is provided with a carbonization bin 14. The left end of the urceolium is rotatably connected and supported with the exhaust bin 2, and the right end of the urceolus is rotatably connected and supported with the carbonization bin. The outer wall of the middle part of the urceolus is provided with a gear ring 11, and the bottom of the ring gear is provided with a gear 10 driven by a motor 9 as a power source for rotating the urceolus. The outer wall of the outer cylinder is respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com