Pre-harvest spraying preservative for strawberries in greenhouse and spraying method thereof

A preservative, strawberry technology, applied in horticultural methods, fruit and vegetable preservation, botanical equipment and methods, etc., can solve problems such as mechanical damage and rot, avoid drug injury, reduce rot diseases, and control pre-harvest disease infection and postharvest decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

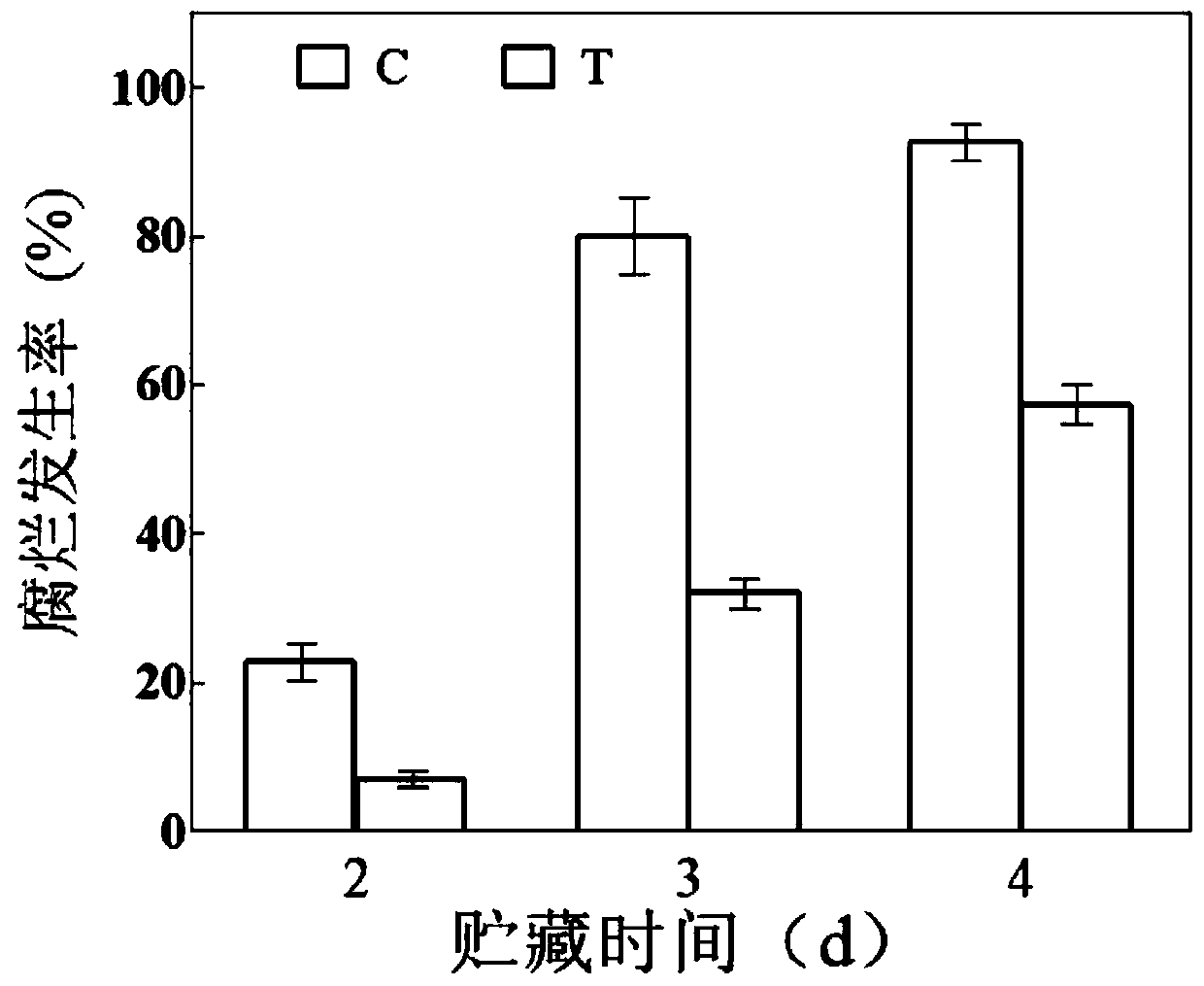

Image

Examples

Embodiment 1

[0015] A pre-harvest spraying preservative for strawberries in greenhouses. The specific formula is as follows: After mixing tea tree essential oil and solidago canadensis essential oil in a volume ratio (5-7): (5-3), add Tween with 1% of the mass of the mixture to obtain essential oil emulsion Turbid liquid, that is, strawberries are sprayed with preservatives before harvesting. The extraction process of the solidago canadensis essential oil is as follows: collecting solidago canadensis from the end of September to the beginning of October every year, drying the leaves and flowers, and steam distillation to obtain the solidago canadensis essential oil.

Embodiment 2

[0017] The spraying method of the pre-harvesting preservative spraying of strawberries in the greenhouse described in the above-mentioned embodiment 1, the specific steps are as follows: the spraying cycle is 6, 3, and 0 days before the listing period of a batch of strawberries, spraying in 3 times, each time spraying with foliage Evenly covered with foggy water droplets (the solvent is water); each spraying time is 5-6 o'clock in the morning, after spraying, the greenhouse is sealed for 2 hours, and then both sides of the greenhouse are opened for ventilation for half an hour.

[0018] Among them, 6 days before the harvest period, spray 5 ml / L of strawberry preharvest spray preservative solution, the volume ratio of tea tree essential oil and solidago canadensis essential oil in the preservative is 5:5;

[0019] 3 days before harvest, spray 2.5 ml / L strawberry pre-harvest spray preservative solution, the volume ratio of tea tree essential oil and solidago canadensis essential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com