Thin-film sheet including cellulose fine-fiber layer

A technology of microfiber and film sheet, applied in the direction of synthetic cellulose fiber, post-treatment modification of cellulose pulp, separator/film/diaphragm/spacer element, etc. , low internal resistance and other issues, to achieve the effect of taking into account thermal stability, excellent chemical stability/physical stability, and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

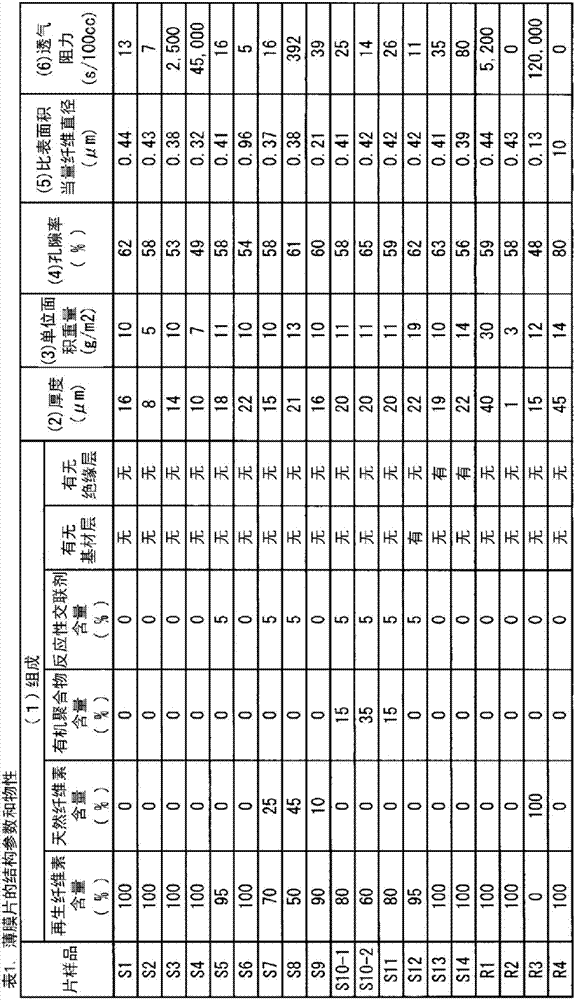

Embodiment 1

[0196] Tencel cut yarns (3 mm long) which are regenerated cellulose fibers purchased from Sojitz Corporation were put into a cleaning net, a surfactant was added, and washed several times in a washing machine to remove the oil on the surface of the fibers. The obtained refined tencel fiber (cut yarn) was dispersed in water (400 L) so that the solid content reached 1.5% by weight, and as a disc refiner device, SDR14 type LAB REFINER (pressurized DISK type) manufactured by Aikawa Iron Works Co., Ltd. was used. ), the gap between the discs was set as 1mm, and this aqueous dispersion of 400L was subjected to knocking treatment for 20 minutes. Thereafter, beating was thoroughly performed under the condition that the gap was reduced to a level substantially close to zero, thereby obtaining a beating aqueous dispersion (solid content concentration: 1.5% by weight). Using a high-pressure homogenizer (NS015H manufactured by Niro Soavi (Italy)), under an operating pressure of 100MPa, th...

Embodiment 2

[0201] For the papermaking slurry prepared by diluting M1 of Example 1 with water to form a weight per unit area of 5 g / m 2 The form of the fine cellulose sheet was adjusted, and the papermaking slurry thus obtained was thrown in. In addition, the same operation was carried out as in Example 1, thereby obtaining the white fine cellulose shown in the following table 1. Thin film sheet S2.

Embodiment 3

[0203] Use high-pressure homogenizer (NS015H manufactured by Niro Soavi company (Italy)), under the operating pressure of 100MPa, directly carry out 10 processings to the knocked water dispersion (solid content concentration: 1.5% by weight) obtained in embodiment 1, except Otherwise, the same operation as in Example 1 was carried out to obtain a film sheet S3 made of white fine cellulose shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impermeability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com