Fabrication method of ring cavity surface emission difference frequency terahertz quantum cascade laser

A quantum cascade, terahertz technology, applied in lasers, solid-state lasers, laser parts, etc., can solve the problem of low outcoupling efficiency of terahertz light, and achieve the goal of improving outcoupling efficiency, improving far-field divergence, and improving heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

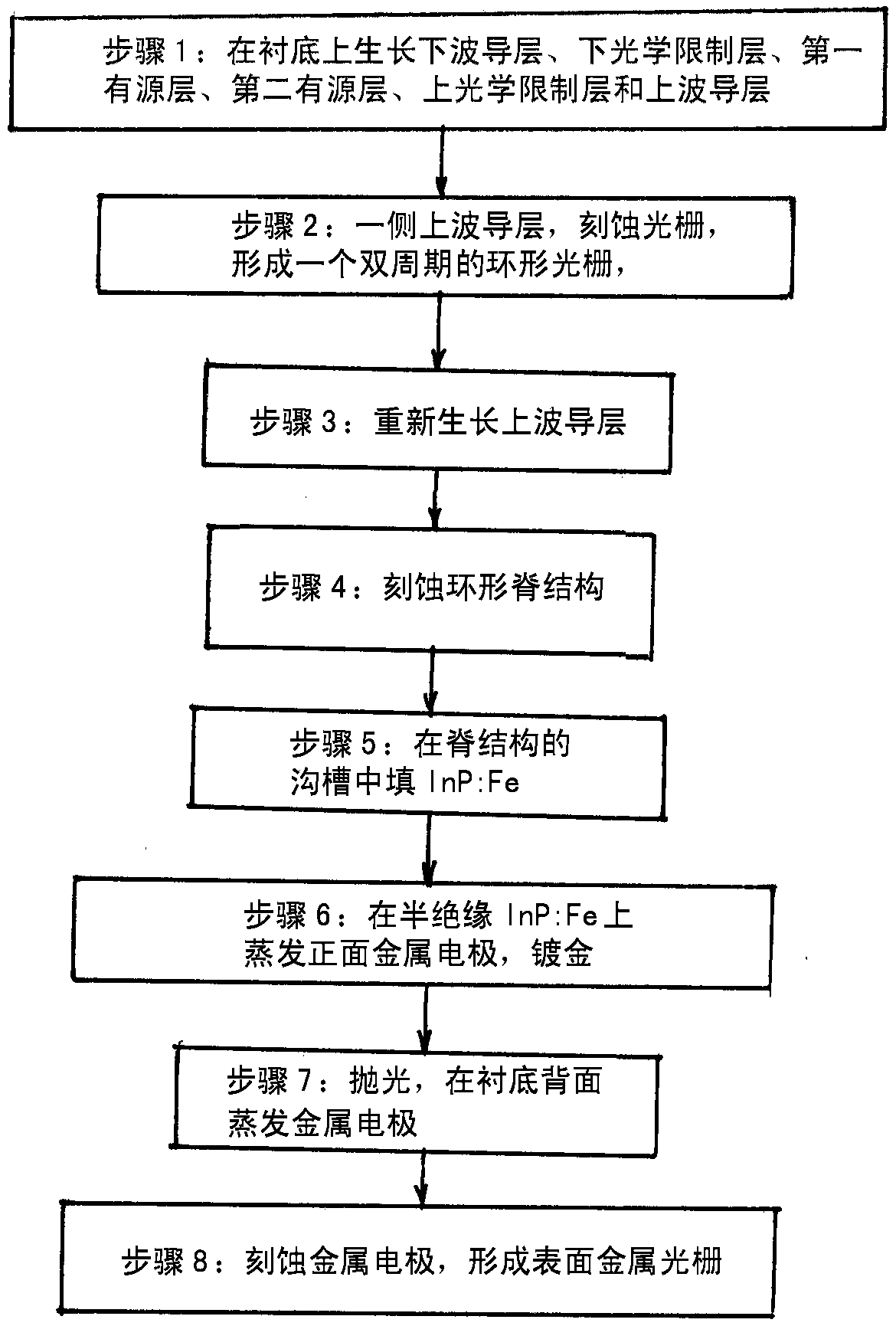

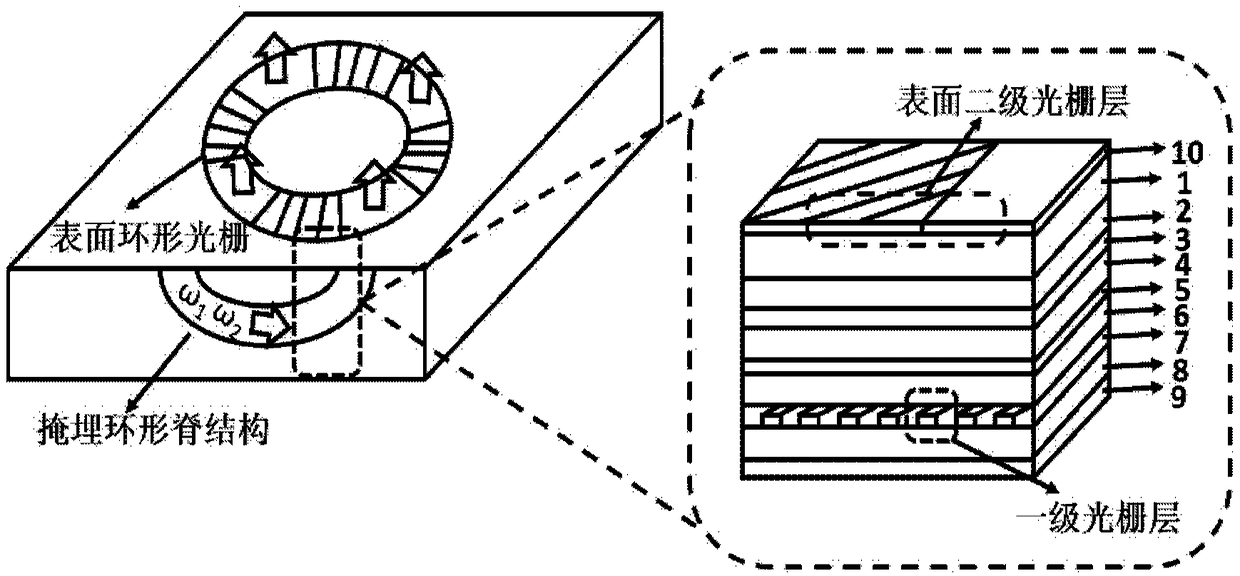

[0019] see figure 1 and figure 2 As shown, the present invention provides a method for preparing a ring-cavity surface-emitting difference-frequency terahertz quantum cascade laser, comprising the following steps:

[0020] Step 1: On a substrate 1, grow the lower waveguide layer 2, the lower optical confinement layer 3, the first active layer 4, the spacer layer 5, the second active layer 6, the upper optical confinement layer 7 and the upper waveguide layer 8. The material of the substrate 1 is n-type doped semi-insulating InP, the material of the lower waveguide layer 2 is n-type doped InGaAs, and the material of the lower optical confinement layer 3 is n-type Doped InP, the first active layer 4 and the second active layer 6 are composed of 20-40 periods of InGaAs / InAlAs quantum wells, the first active layer 4 and the second active layer 6 correspond to The wavelength is 7-11 μm, the material of the spacer layer 5 is n-type doped InGaAs, the material of the upper optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com