A light extraction film having hollow bubbles and an organic light-emitting diode and a processing method thereof

A technology of light extraction film and air bubbles, which is applied in the direction of organic semiconductor devices, electrical components, electric solid devices, etc., can solve the problems of inability to output light, achieve the effect of improving coupling light output efficiency, avoiding total reflection, and improving outcoupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

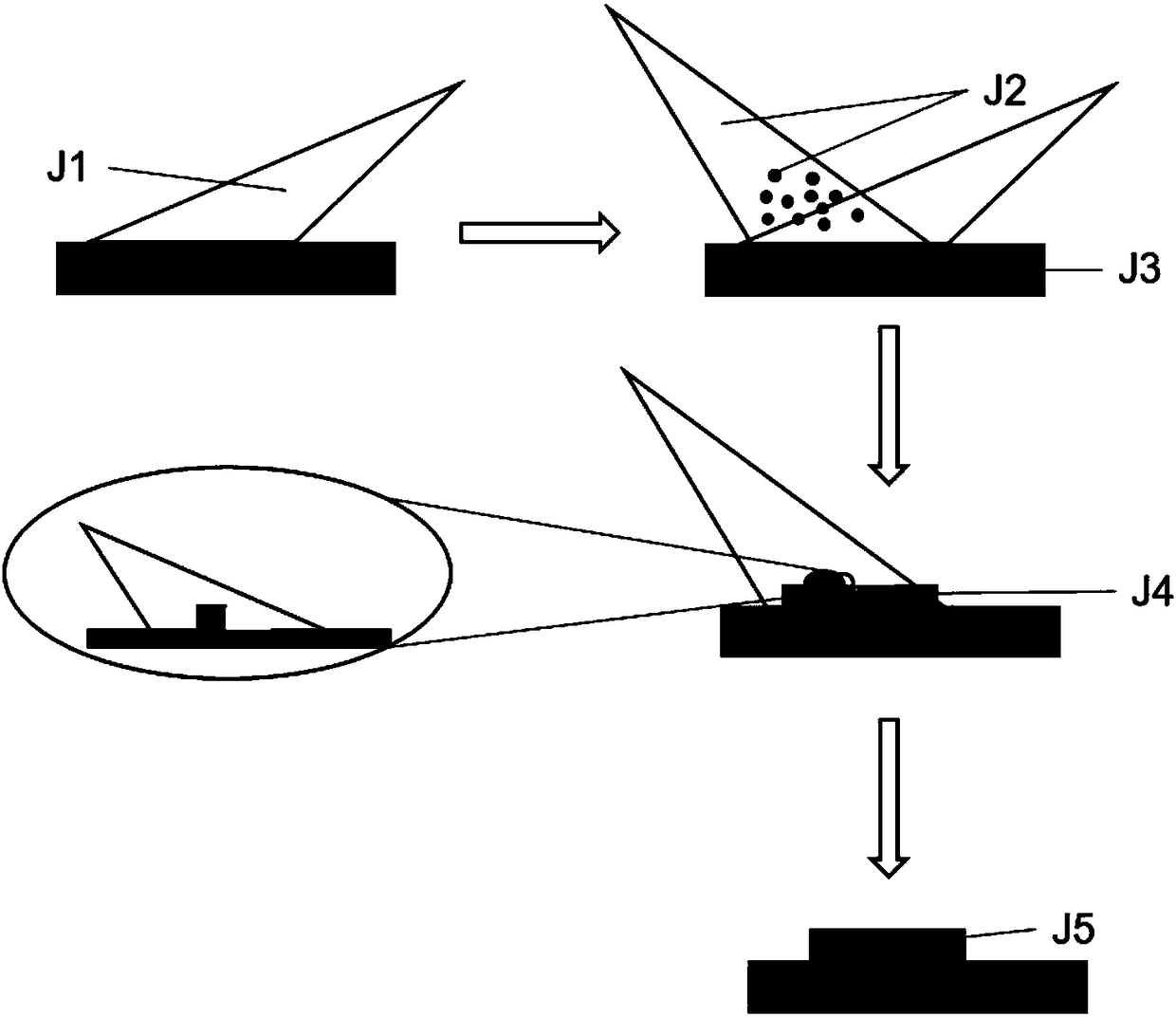

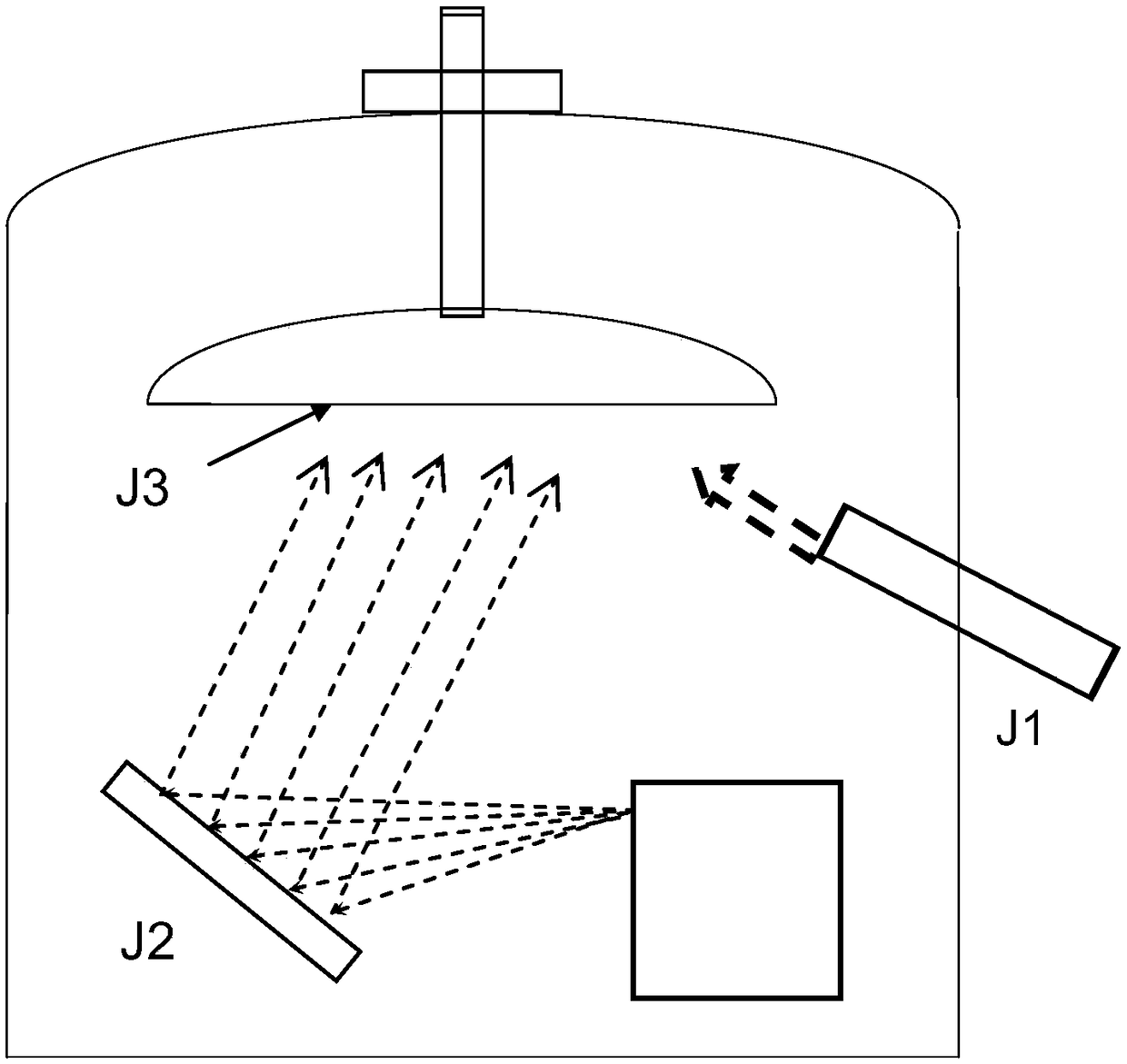

Method used

Image

Examples

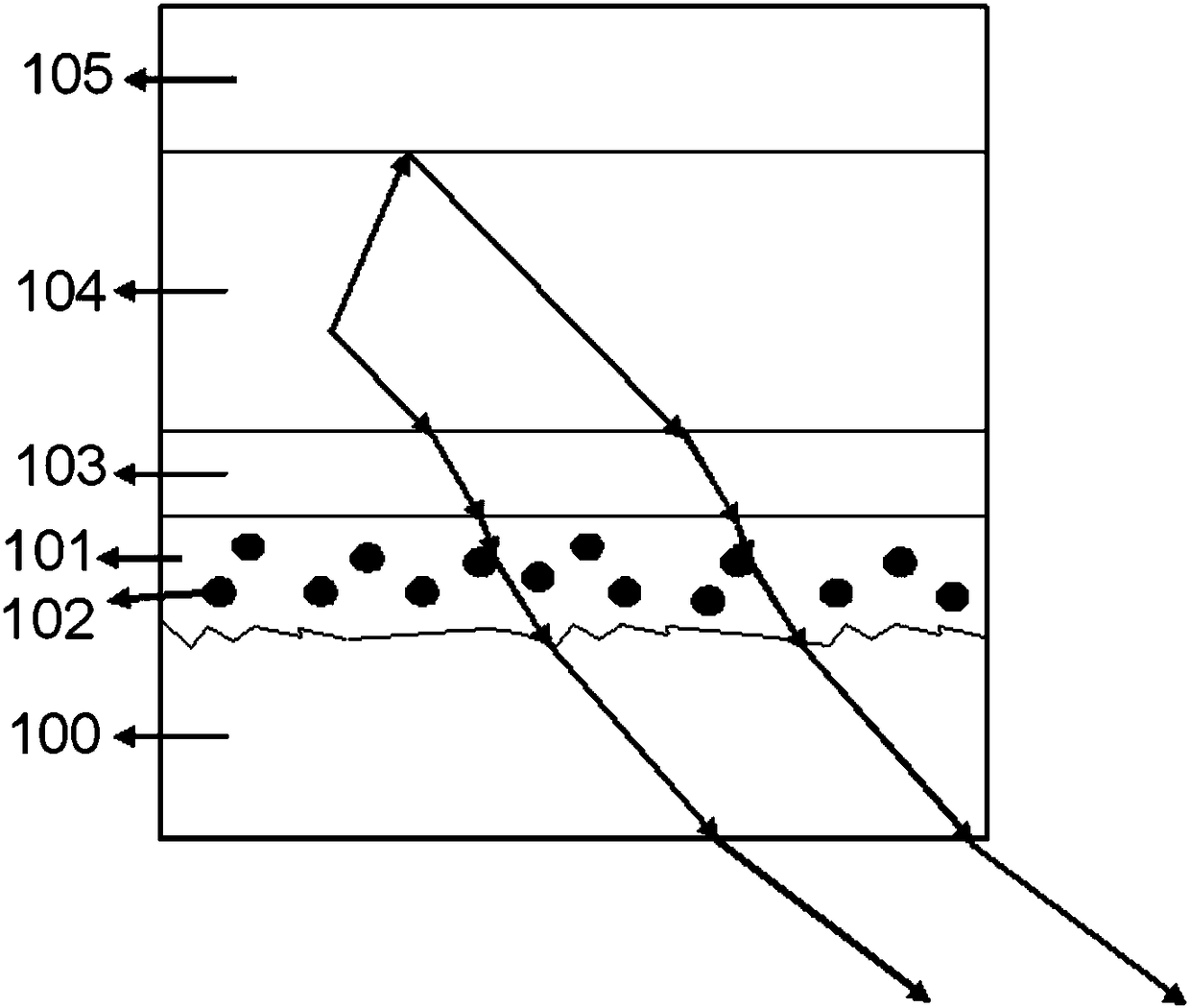

Embodiment 1

[0043] Such as image 3 As shown, this example includes a glass plate on which a light extraction film is compounded. The light extraction film contains hollow bubble holes. The main material of the extraction film is TiO 2 , The film is deposited on the glass plate by a dual ion coater. In the structure in this example, the light emitted from the light-emitting layer propagates in two directions up and down, and the light propagating upward is reflected by the metal cathode and finally propagates downward. The reflected light and the downward light from the light source respectively pass through the organic layer, the ITO layer and the TiO 2 Since the multi-bubble film provided by the present invention can effectively provide astigmatism, it can be effectively extracted and transferred to ITO / TiO 2 The light of the interface. Thereby improving the overall coupling efficiency of the device. The multi-bubble film is the inner light emitting film of the OLED device, and the prepa...

Embodiment 2

[0049] Such as Figure 4 As shown, this example includes a glass plate on which a light extraction film is compounded, and the light extraction film contains hollow bubble holes. The main material of the extraction film is SiO 2 , The film is deposited on the glass plate by a dual ion coater. In the structure in this example, the downwardly transmitted light enters the glass / external extraction film interface after passing through the glass substrate. Like the main body of the glass substrate, the main material of the outer extraction film is also SiO 2 , The refractive index is matched, and the light transmitted in the glass can be well absorbed. Under the action of the gas in the film, the absorbed light is scattered and transferred to the air. In this example, the multi-bubble outer extraction film structure can reduce the substrate mode during the light extraction process, thereby improving the efficiency of the device as a whole. The multi-bubble film is the light-emittin...

Embodiment 3

[0055] Such as Figure 5 As shown, two layers of multi-bubble structures are prepared using the same process and the structured films are respectively applied to the inner extraction film and the outer extraction film of the device. The main material of the inner extraction membrane is TiO 2 , The main material of the outer extraction film is SiO 2 This structure can reduce the waveguide mode and the substrate mode during the light output process of the device, thereby improving the light output coupling efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com