Mobile communication base station antenna

A mobile communication base station and antenna technology, applied in the direction of antenna, antenna components, antenna grounding switch structure connection, etc., can solve the problems of high melting point, no solution, inability to adapt to development, etc., and achieves good electrical and thermal conductivity and stable signal reception. , the effect of mature molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific examples.

[0045] The invention relates to a base station antenna for mobile communication. The main components of the antenna are made of magnesium alloy materials. The components and weight percentages of the magnesium alloy are: manganese (Mn) 0.1-1.0%, zinc (Zn) 0.1- 1.0%, silicon (Si) 0.001-1.4%, copper (Cu) 0.001-0.25%, aluminum (Al) 3-10%, nickel (Ni) ≤ 0.005%, iron (Fe) ≤ 0.005%, lead (Pb) 0.005%, impurity ≤ 0.3%, the rest is magnesium (Mg). Raw materials and auxiliary materials are configured according to the above proportions, preheated in the melting furnace (crucible), smelted by heating, refining, casting and other refining processes to obtain magnesium alloy ingots (magnesium alloy blanks), which are processed into the required corresponding magnesium alloy ingots. Material form, such as sheet, bar, etc.

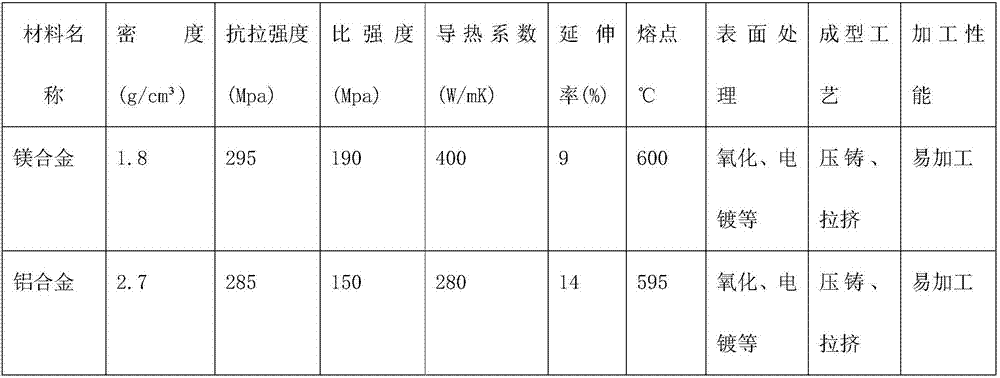

[0046]The general material of the main metal parts in the base sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com