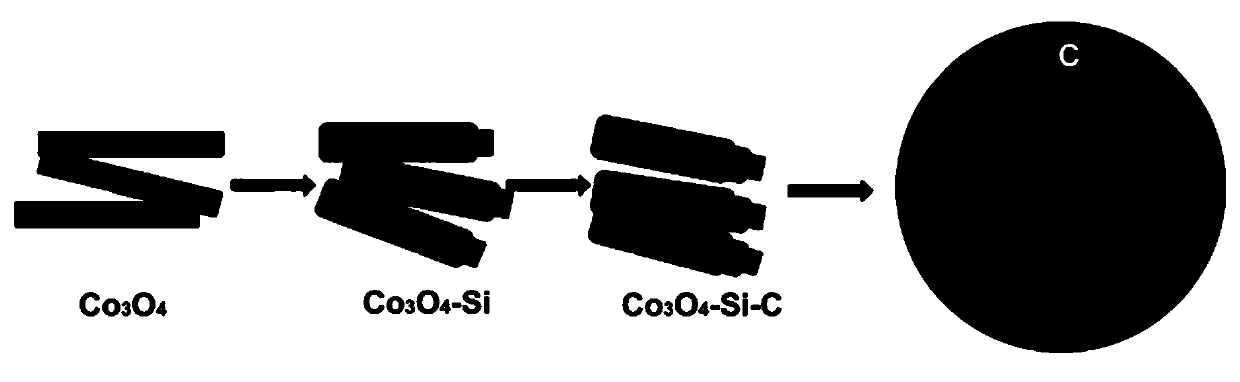

Preparation method of a three-dimensional composite CO3O4-Si-C negative electrode material

A co3o4-si-c, negative electrode material technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve problems such as unfavorable lithium ion and electron transportation, affecting cycle performance, SEI film thickness, etc., to achieve excellent electrochemical performance, improved specific capacity, and beneficial effects of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

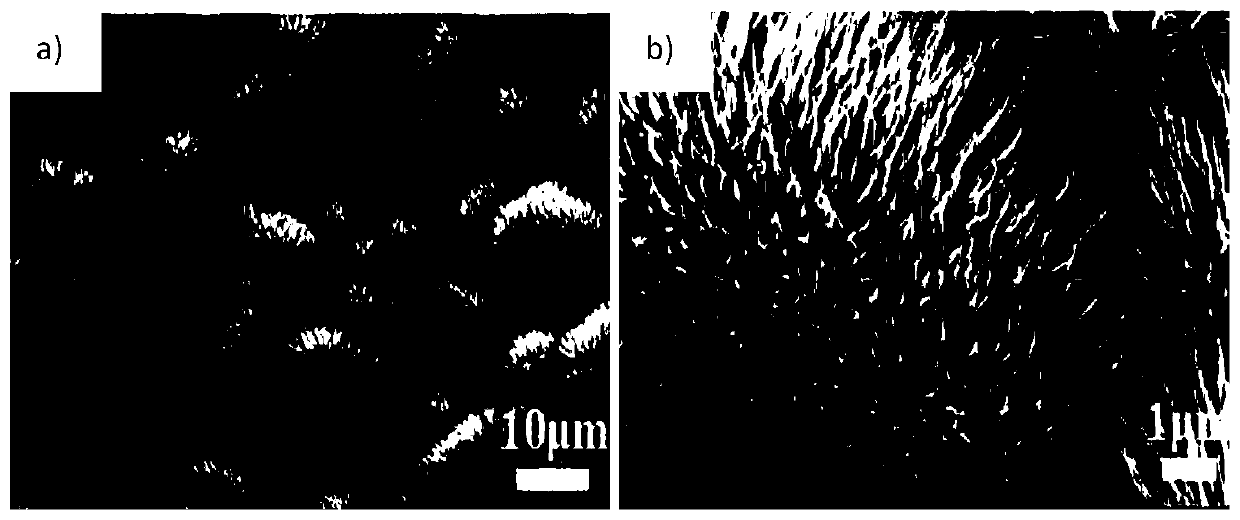

Embodiment 1

[0023] First soak nickel foam in 30% concentrated nitric acid for 5 minutes to remove the oxide layer on the surface, and then add 1.46g of Co(NO 3 ) 2 6H 2 O, 0.37 g NH 4 F and 1.5g of CO(NH 2 ) 2 Dissolve in 50 ml of distilled water, and the entire addition process is performed under magnetic stirring. After stirring for 30 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave, put the trimmed nickel foam into the tetrafluoroethylene, fill the reaction solution with 80%, and react at 120°C for 5 hours. After the reaction, wait for it to cool down to the room temperature range, then alternately wash three times with deionized water and ethanol to remove impurities, and then treat it in a drying oven at 80 °C for 12 h. Finally, high-temperature roasting at 450° C. for 3 h gave the desired product. The soluble silicon source was dissolved in the ionic liquid system, and the prepared Co 3 o 4 The nanoarray was used as the cathode, the Pt...

Embodiment 2

[0025]First soak nickel foam in 30% concentrated nitric acid for 5 minutes to remove the oxide layer on the surface, and then add 1.46g of Co(NO 3 ) 2 6H 2 O, 0.37 g NH 4 F and 1.5g of CO(NH 2 ) 2 Dissolve in 50 ml of distilled water, and the entire addition process is performed under magnetic stirring. After stirring for 30 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave, put the trimmed nickel foam into the tetrafluoroethylene, and fill the reaction solution with 80%. Reaction 5h. After the reaction, wait for it to cool down to the room temperature range, then alternately wash three times with deionized water and ethanol to remove impurities, and then treat it in a drying oven at 80 °C for 12 h. Finally, high-temperature roasting at 450° C. for 3 h gave the desired product. The soluble silicon source was dissolved in the ionic liquid system, and the Co 3 o 4 The nanoarray was used as the cathode, the Pt mesh electrode was used...

Embodiment 3

[0027] First soak nickel foam in 30% concentrated nitric acid for 5 minutes to remove the oxide layer on the surface, and then add 1.46g of Co(NO 3 ) 2 6H 2 O, 0.37 g NH 4 F and 1.5g of CO(NH 2 ) 2 Dissolve in 50 ml of distilled water, and the entire addition process is performed under magnetic stirring. After stirring for 30 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave, put the trimmed nickel foam into the tetrafluoroethylene, and fill the reaction solution with 80%. Reaction 5h. After the reaction, wait for it to cool down to the room temperature range, then alternately wash three times with deionized water and ethanol to remove impurities, and then treat it in a drying oven at 80 °C for 12 h. Finally, high-temperature roasting at 450° C. for 3 h gave the desired product. The soluble silicon source was dissolved in the ionic liquid system, and the Co 3 o 4 The nanoarray was used as the cathode, the Pt mesh electrode was use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com