An anti-interference synchronous sliding mode control method for a hybrid automobile electrophoretic coating conveying mechanism

A technology of electrophoretic coating and conveying mechanism, applied in the direction of adaptive control, general control system, control/adjustment system, etc., to solve chattering and actuator saturation, improve anti-interference performance, good trajectory tracking performance and synchronous coordination performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

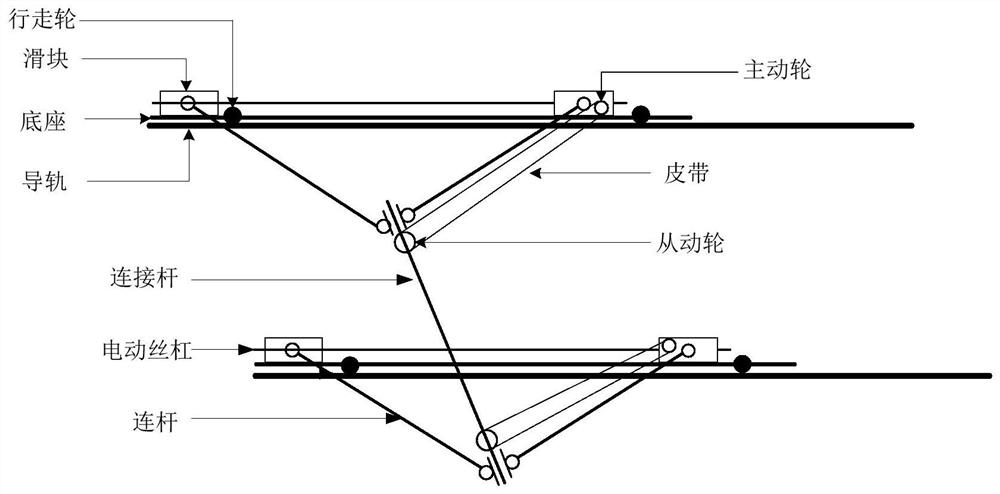

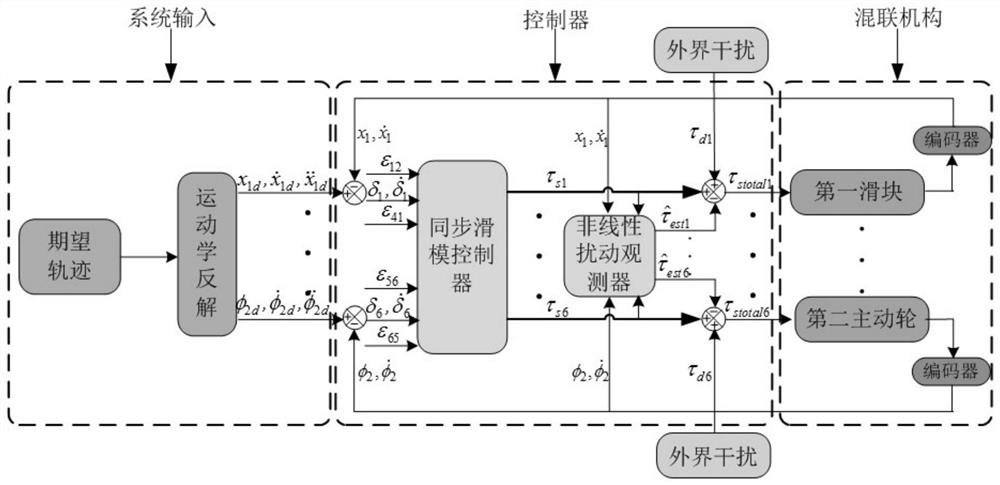

[0103] The present invention mainly focuses on using an anti-interference synchronous sliding mode control method to improve the motion control performance of the hybrid automobile electrophoretic coating conveying mechanism, so as to enhance the robustness and anti-interference of the system while improving the synchronous coordination of the mechanism capability, and suppress problems such as chattering and actuator saturation. The block diagram of the anti-jamming synchronous sliding mode control principle of the hybrid automobile electrophoretic coating conveying mechanism is as follows: figure 2 As shown, the specific implementation of the control method is as follows:

[0104] 1. Establish a dynamic model of the lifting and turning mechanism with unmodeled dynamics, friction and external random disturbances

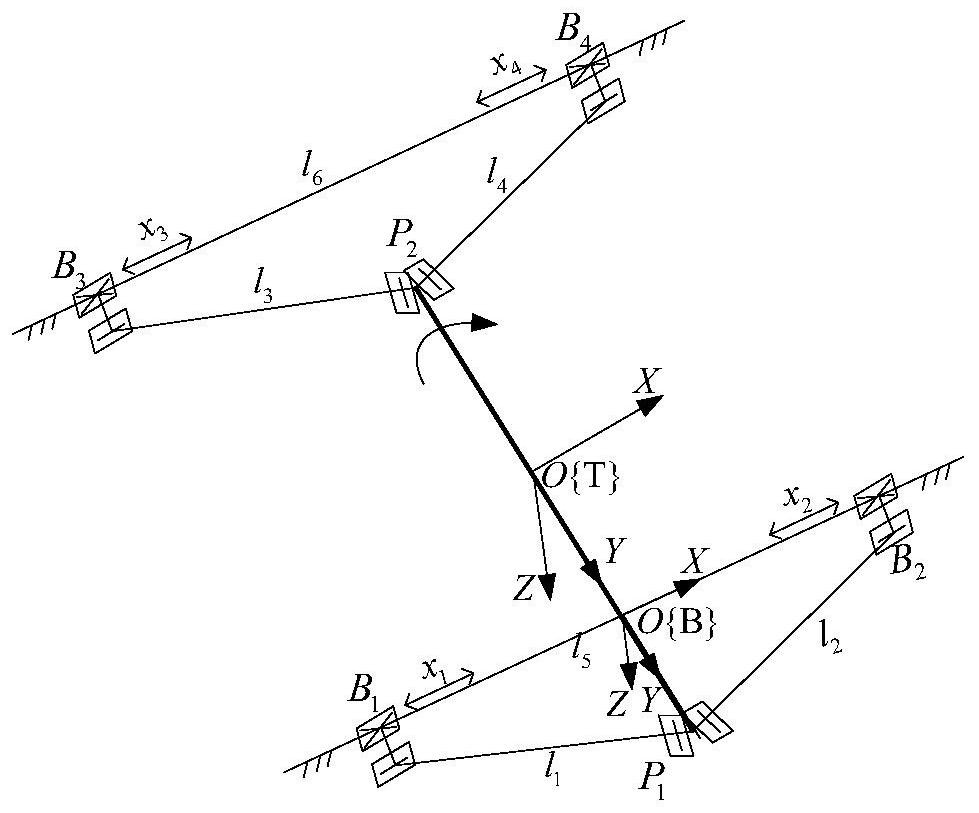

[0105] based on image 3 The dynamic coordinates {T}={O-XYZ} established as shown, using the Lagrangian method, the pose parameters of the midpoint of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com