Intelligent infrared thermal imaging device and inspection method for power grid device on-line inspection

A technology of infrared thermal imaging and power grid equipment, applied in the direction of circuit devices, overhead lines/cable equipment, measuring devices, etc., can solve the problems that are not conducive to the unified management and application of data, the decline of work efficiency, and low work efficiency, so as to improve the reuse The effect of improving efficiency, guaranteeing operating time, and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

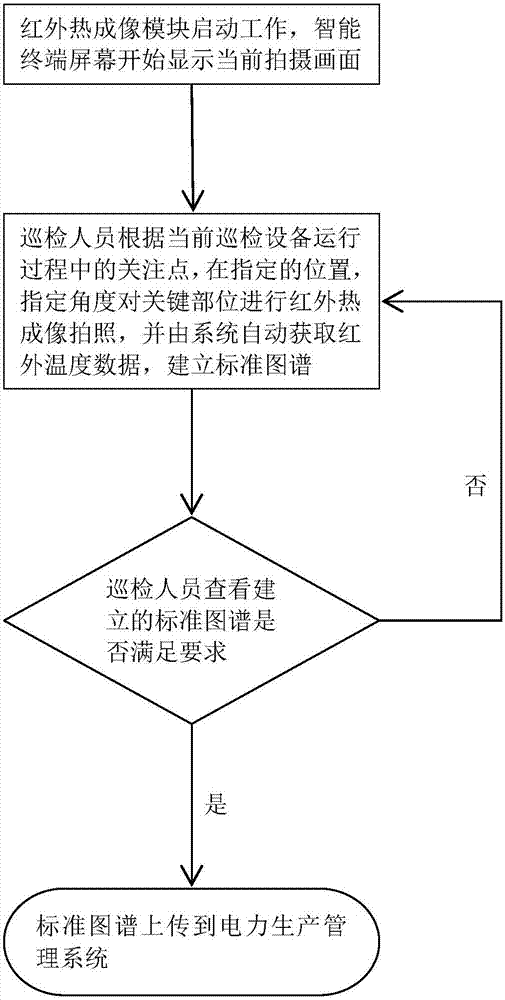

Image

Examples

Embodiment 1

[0111] Specific embodiment 1: RFID code scanning module, infrared thermal imaging module, communication control module, power supply module, intelligent terminal;

[0112] For power grid operation equipment equipped with RFID electronic tags, this implementation mode is adopted during inspection to form an intelligent infrared thermal imaging device for online inspection of power grid equipment.

[0113] The RFID code scanning module, the infrared thermal imaging module, the communication control module, and the power supply module are packaged in a shell through a wired connection board. Smart terminals are embodied in the form of tablet computers, smart phones, or other types of smart data terminals, and can also be replaced by information industry tablets that are currently widely used by power companies. The two communicate through wireless (wifi) or wired (RJ45, USB), and the physical connection between the two adopts a buckle-type convenient and detachable method.

[01...

Embodiment 2

[0116] Barcode scanning module, infrared thermal imaging module, communication control module, power supply module, intelligent terminal

[0117] For power grid operation equipment with barcode labels, this implementation mode is adopted during inspection to form an intelligent infrared thermal imaging device for online inspection of power grid equipment.

[0118] The barcode scanning module, the infrared thermal imaging module, the communication control module, and the power supply module are packaged in a shell through a wired connection board. Smart terminals are embodied in the form of tablet computers, smart phones, or other types of smart data terminals, and can also be replaced by information industry tablets that are currently widely used by power companies. The two communicate through wireless (wifi) or wired (RJ45, USB), and the physical connection between the two adopts a buckle-type convenient and detachable method.

[0119] During the inspection operation, use th...

Embodiment 3

[0121] Including RFID scanning module, barcode scanning module, infrared thermal imaging module, communication control module, power supply module, intelligent terminal.

[0122] The RFID scanning module, barcode scanning module, infrared thermal imaging module and mobile intelligent terminal are combined to form an intelligent infrared thermal imaging device for online inspection of power grid equipment. According to the situation of the inspection site grid equipment, select different scanning methods to obtain the identity information of the inspection grid equipment.

[0123] The RFID scanning module, the barcode scanning module, the infrared thermal imaging module, the communication control module, and the power supply module are packaged in a shell through a wired connection board. Smart terminals are embodied in the form of tablet computers, smart phones, or other types of smart data terminals, and can also be replaced by information industry tablets that are currently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com