A Wavelength Scanning 3D Shape Measurement System Referenced by an Optical Frequency Comb

A technology of wavelength scanning and three-dimensional topography, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of increased environmental impact of measurement results, increased measurement time consumption, etc., to achieve fast measurement, slow measurement speed, and measurement The effect of error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

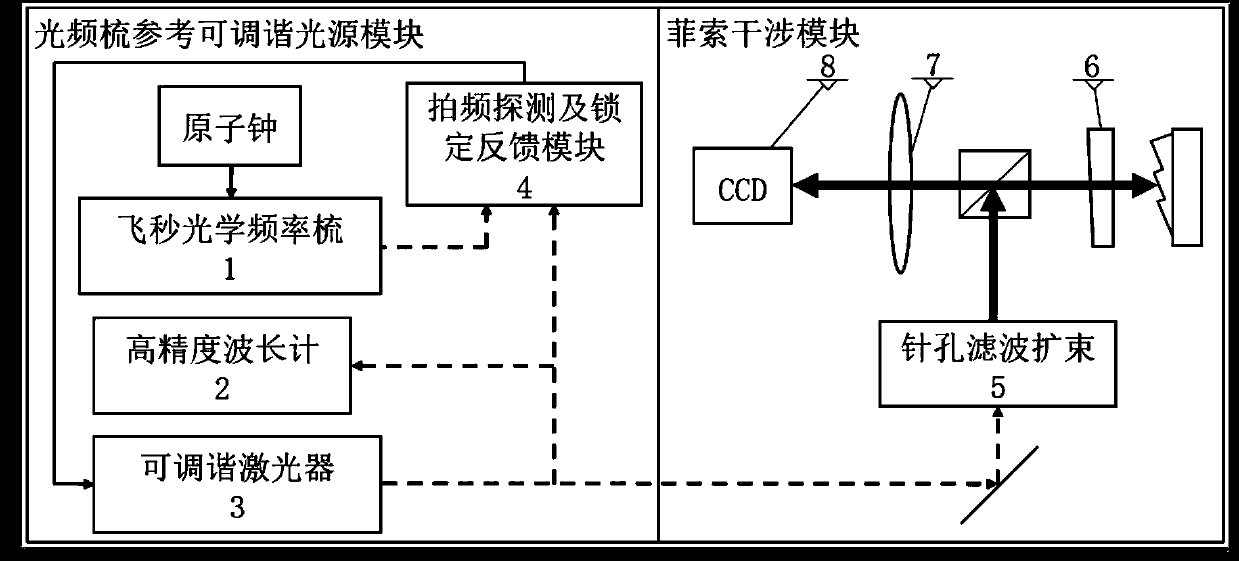

[0028] Such as figure 1 As shown, the measurement system of the present invention includes a tunable laser light source system based on an optical frequency comb reference and an interferometric optical path system. It specifically includes femtosecond optical frequency comb 1, high-precision wavelength meter 2, external cavity semiconductor tunable laser 3, beat frequency detection and locking feedback module 4, pinhole filter 5, reference plane 6, imaging lens group 7 and CCD 8.

[0029]Femtosecond Optical Frequency Comb 1 is a fully stable femtosecond pulsed mode-locked laser. The laser corresponds to a series of frequencies arranged at equal intervals in the frequency domain. Because its shape is similar to a comb, it is also called an optical frequency comb. The frequency corresponding to each comb tooth is determined by the repetition f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com