Non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric and preparation method thereof

A bulletproof cloth, high temperature resistance technology, applied in the direction of flame retardant fibers, textiles, yarns, etc., can solve the problems of poor high temperature resistance, heavy bulletproof cloth, poor heat insulation effect, etc., and achieve excellent heat insulation performance and high temperature resistance. Excellent, excellent acid and alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

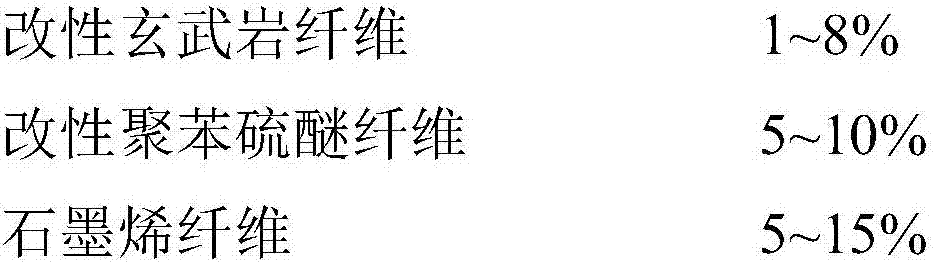

[0036] A non-combustible, acid-alkali-resistant, high-temperature-resistant bulletproof cloth, the mass percentage of each component is as follows:

[0037]

[0038] 8 kg of basalt fibers were passed through sodium hydroxide solution at 80°C, water vapor at 150°C, hydrochloric acid vapor at 150°C, and water vapor at 100°C in sequence. After cooling and drying, they were immersed in a graphene oxide solution containing 2% by mass fraction of nano-alumina. After 25 minutes, take it out and dry it, then pass through ethanol vapor at 200°C and water vapor at 80°C in sequence, and cool and dry to obtain 8.36kg of modified basalt fiber;

[0039] Put 20kg of titanium wire in a 5% mass concentration dilute hydrochloric acid solution for 40 seconds, take it out, wash and dry it, then dip it in a graphene oxide solution containing 1.5% carbon nanotubes by mass fraction, take it out and dry it after 15 minutes, and then pass through Ammonia gas at 120°C, ethanol vapor at 180°C, washed...

Embodiment 2

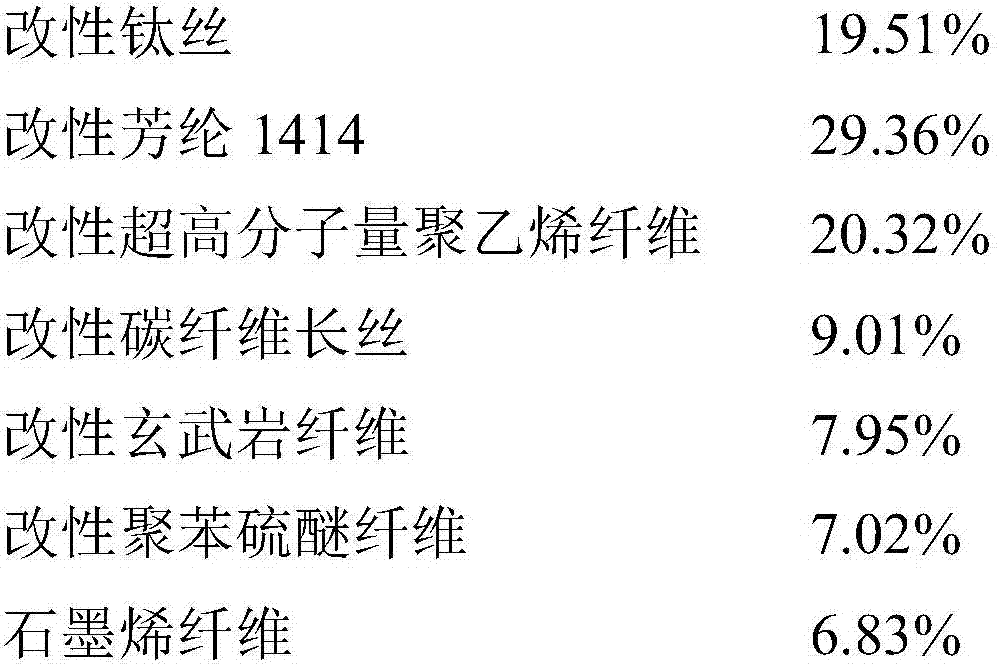

[0054] A non-combustible, acid-alkali-resistant, high-temperature-resistant bulletproof cloth, the mass percentage of each component is as follows:

[0055]

[0056] 3 kg of basalt fibers were sequentially passed through sodium hydroxide solution at 75°C, water vapor at 175°C, hydrochloric acid vapor at 150°C, and water vapor at 102°C. After cooling and drying, they were immersed in a graphene oxide solution containing 2% by mass fraction of nano-alumina. After 25 minutes, take it out and dry it, then pass through ethanol vapor at 230°C and water vapor at 80°C in sequence, and cool and dry to obtain 3.12kg of modified basalt fiber;

[0057] Put 30kg of titanium wire in a 5% mass concentration dilute hydrochloric acid solution for 15 seconds, take it out, wash and dry it, then dip it in a graphene oxide solution containing 1.5% carbon nanotubes by mass fraction, take it out and dry it after 12 minutes, and then pass through Ammonia gas at 150°C, ethanol vapor at 182°C, washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com