Railway brake beam material XWQ470E and machining method

A technology for braking beams and railways, applied in the direction of improvement of process efficiency, furnace type, furnace, etc., can solve problems such as low fatigue limit, low performance index, and easy surface cracks, so as to improve impact toughness and reduce Widmanstatten structure Content, the effect of improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

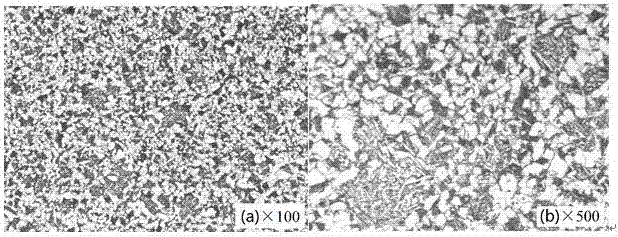

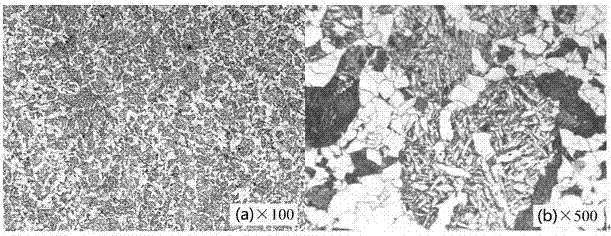

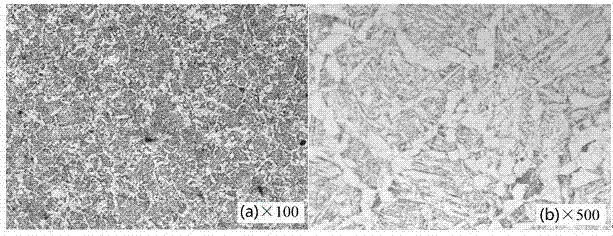

Image

Examples

Embodiment Construction

[0052] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples and accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0053] A railway brake beam material XWQ470E, its composition (Wt.%) is: C: 0.12~0.20, Si: 0.25~0.35, Mn: 1.20~1.50, P≤0.020, S≤0.010, Cr: 0.20~0.30, Ni: 0.30-0.55, Mo≤0.20, V: 0.08-0.14, Al: 0.015-0.035, Nb: 0.015-0.030, Ce: 0.001-0.03, and the balance is composed of iron and unavoidable impurities.

[0054] The preparation method of railway brake beam material XWQ470E comprises the following process steps:

[0055] (1) Electric furnace smelting:

[0056] The raw materials are composed of molten iron, pig iron block, and scrap steel. Slag steel is not allowed, and nickel-containing pig iron is mixed in proportion; when hot charging molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com