Inorganic binder refractory artificial board material and preparation method thereof

An inorganic binder and artificial board technology, applied in the field of wood industry, can solve the problems of insufficient fire resistance and thermal stability, complicated preparation, environmental pollution, etc., and achieve the effects of good fire resistance, simple preparation process and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

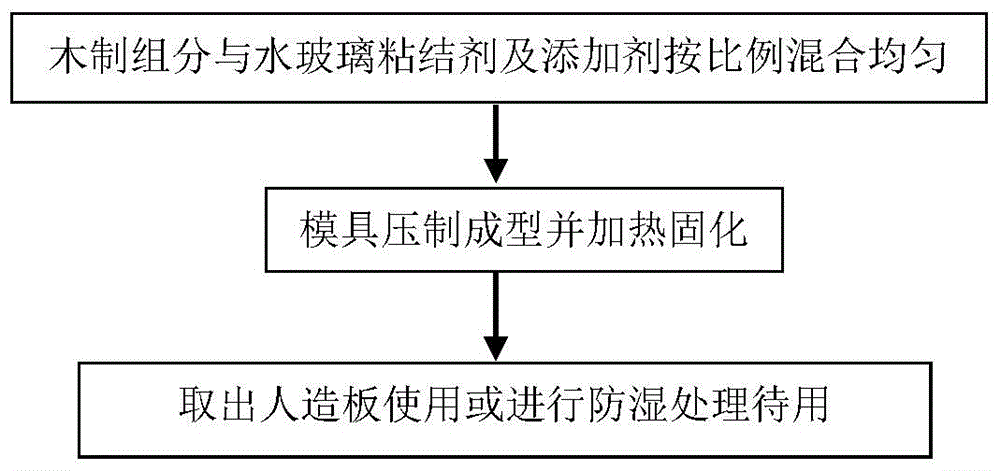

[0030] According to another aspect of the present invention, also provide a kind of preparation method of inorganic binder refractory wood-based panel material, comprise the following steps:

[0031] (1) mix and stir the wooden component and the water glass binder at normal temperature, thus obtain the mixture sawdust;

[0032] (2) put the mixed material sawdust obtained into the mould, press and form it and heat it, and after heating and solidifying, demold to obtain the inorganic binder refractory wood-based panel;

[0033] (3) In the case of high ambient humidity, the inorganic binder refractory wood-based panels obtained in (2) were subjected to moisture-proof treatment.

[0034] In step (1), the mass ratio of the wooden component to the water glass binder is 1:0.5-1:3, and the modulus of the water glass binder is 1.5-3.0.

[0035] In step (2), the pressing pressure is 4MPa-20MPa.

[0036] In step (3), the moisture-proof treatment includes adding a moisture-resistant mod...

Embodiment 1

[0040] Inorganic binder refractory wood-based panel material preparation: 50 parts of sawdust, 150 parts of potassium silicate (modulus about 3.0).

[0041] Add the sawdust to the mixer at room temperature, then add the inorganic binder and mix evenly to obtain the mixed sawdust; then pave the mixed sawdust in the mold and press it under a pressure of 4 MPa and heat it. After heating and solidifying, demould and cool to obtain the inorganic Adhesive refractory wood-based panels.

[0042] According to the three-point bending method specified in GB / T 17657-2013, the static bending strength of the inorganic binder fire-resistant wood-based panels obtained in this example is 13MPa-15MPa.

Embodiment 2

[0044] Inorganic binder refractory wood-based panels were produced according to the method of Example 1, except that an additional 3 parts of organic esters were added to the mixture sawdust.

[0045]According to the three-point bending method specified in GB / T 17657-2013, the static bending strength of the inorganic binder fire-resistant wood-based panel obtained in this example is 12MPa-14MPa, which is lower than the moisture absorption rate of the inorganic binder fire-resistant wood-based panel in Example 1 3% to 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com