Baking-free brick using coal gangue and red mud as main materials, and preparation method for baking-free brick

A technology of coal gangue and unburned bricks, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high compressive strength, achieve the effects of improving strength, reducing production costs, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

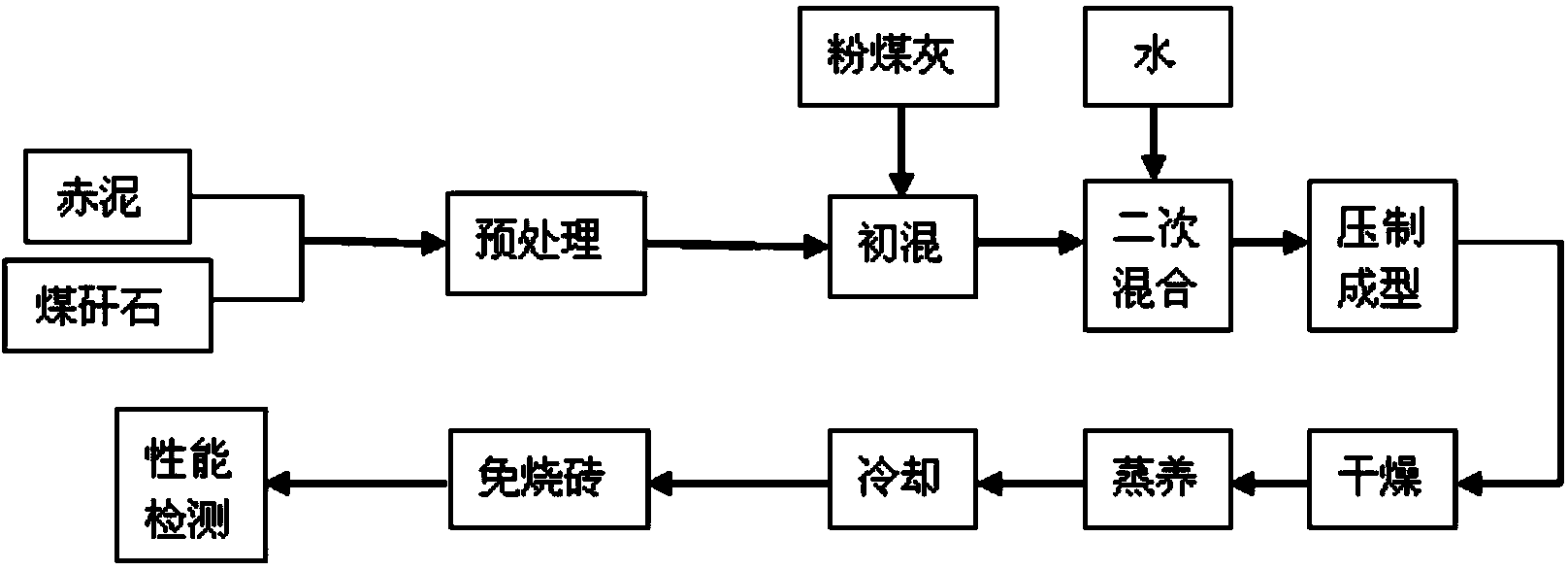

Method used

Image

Examples

Embodiment 1

[0048] A method for producing burn-free bricks with coal gangue and red mud as main raw materials, comprising the following steps:

[0049] 1. Dry the red mud and coal gangue at 105°C for 3 hours respectively. After natural cooling, crush the dried red mud and pass through a 80-mesh sieve to obtain red mud powder. Grind the dried coal gangue and pass through a 100-mesh sieve. Mesh sieve to get gangue powder.

[0050] 2. The fly ash is first dried at 105°C for 3 hours, cooled naturally, and then crushed into a powder with a 100-mesh sieve with a residue of less than 5%.

[0051] 3. Weigh 25g of red mud powder, 20g of coal gangue powder, and 8g of fly ash. Stir and mix the above raw materials evenly for initial mixing. The mixing time for the initial mixing is 3 minutes, then add 8g of water, and then perform secondary mixing after stirring. The mixing time of the secondary mixing was 5 minutes to obtain a mixture. The added water can be tap water, recovered reclaimed water or...

Embodiment 2

[0057] A method for producing burn-free bricks with coal gangue and red mud as main raw materials, comprising the following steps:

[0058] 1. Dry the red mud and coal gangue at 100°C for 3 hours respectively. After natural cooling, crush the dried red mud and pass through a 80-mesh sieve to obtain red mud powder. Grind the dried coal gangue and pass through a 100-mesh sieve. Mesh sieve to get gangue powder.

[0059] 2. The fly ash is first dried at 100°C for 3 hours, cooled naturally, and then crushed into a powder with a 100-mesh sieve with a residue of less than 5%.

[0060] 3. Weigh 35g of red mud powder, 30g of coal gangue powder, and 10g of fly ash. Stir and mix the above raw materials evenly for initial mixing. The mixing time for the initial mixing is 5 minutes, then add 10g of water, and then perform secondary mixing by stirring. The mixing time of the secondary mixing was 3 minutes to obtain a mixture. The added water can be tap water, recovered reclaimed water or ...

Embodiment 3

[0065] A method for producing burn-free bricks with coal gangue and red mud as main raw materials, comprising the following steps:

[0066] 1. Dry the red mud and coal gangue at 105°C for 3 hours respectively. After natural cooling, crush the dried red mud and pass through a 80-mesh sieve to obtain red mud powder. Grind the dried coal gangue and pass through a 100-mesh sieve. Mesh sieve to get gangue powder.

[0067] 2. The fly ash is first dried at 105°C for 3 hours, cooled naturally, and then crushed into a powder with a 100-mesh sieve with a residue of less than 5%.

[0068] 3. Weigh 15g of red mud powder, 10g of coal gangue powder, and 4g of fly ash. Stir and mix the above raw materials evenly for initial mixing. The mixing time for the initial mixing is 5 minutes, then add 8g of water, and then carry out secondary mixing by stirring. The mixing time of the secondary mixing was 4 minutes to obtain a mixture. The added water can be tap water, recovered reclaimed water or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com