Method for converting and extracting resveratrol by means of bacteria

A technology of resveratrol and bacteria, which is applied in the field of bacterial transformation and extraction of resveratrol, can solve the problems of photothermal unstable chemical synthesis of resveratrol, low efficiency of resveratrol, large amount of solvent usage, etc. , to achieve the effect of convenient separation and extraction, simple treatment, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

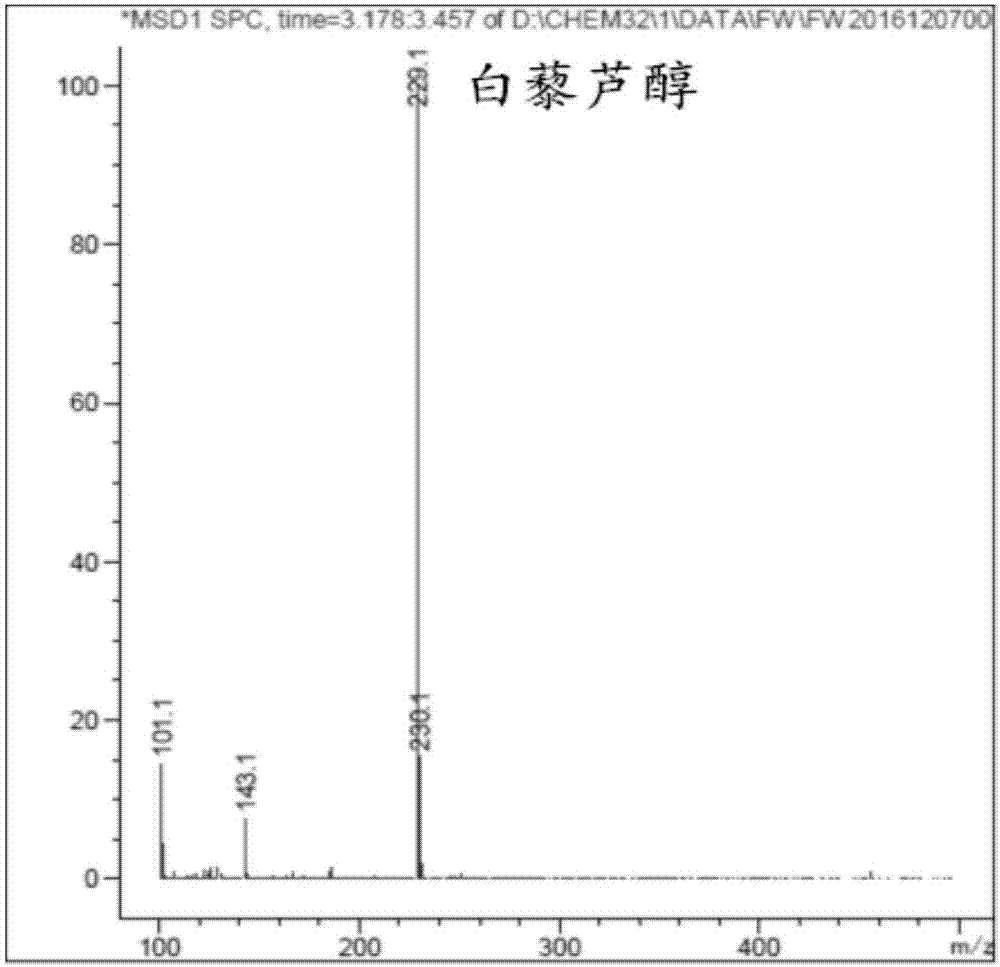

Image

Examples

Embodiment 1

[0028] Add 0.1% substrate Polygonum cuspidatum crude medicinal material to the culture medium (pH=7.0), insert 1% Bacillus shamford seed solution (OD 600nm =1.0), at 37°C, 200r / min, shake flask fermentation for 10h, and the product has been precipitated. Centrifuge at 5000r / min, 4°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add 100% ethanol to the precipitate, and centrifuge again at 5000r / min, 4°C, Discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.3%.

Embodiment 2

[0030] Add 0.3% substrate Polygonum cuspidatum crude drug into the culture medium (pH=7.0), insert 3% Bacillus shamfu seed solution (OD 600nm =0.8), at 28°C, 180r / min shake flask fermentation for 12h, product was precipitated. Centrifuge at 2000r / min, 25°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add ethanol with a purity of 80% to the precipitate, and centrifuge again at 2000r / min, 25°C , discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.3%.

Embodiment 3

[0032] Add 0.1% substrate Polygonum cuspidatum crude medicinal material into the culture medium (pH=5.0), insert 3% Bacillus shamford seed solution (OD 600nm =0.8), at 37°C, 200r / min shake flask fermentation for 6h, product was precipitated. Centrifuge at 3000r / min, 25°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add methanol with a purity of 90% to the precipitate, and centrifuge again at 3000r / min, 25°C , discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com