High thermal conductivity interstitial interface material and preparation method thereof

A technology of interface materials and thermally conductive fillers, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of electromagnetic interference of conductive gaskets, achieve the effects of reducing thermal resistance, efficient heat transfer, and avoiding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

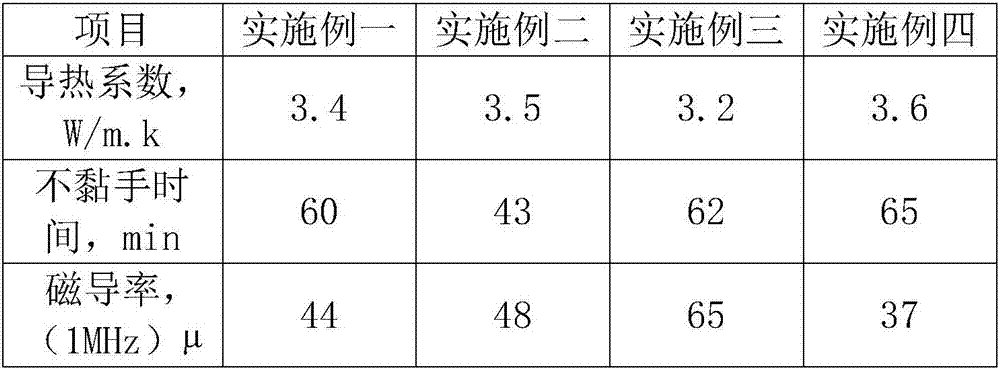

Examples

Embodiment 1

[0026] A highly thermally conductive gap-filling interface material, comprising component A and component B, component A comprising a first main material and a first auxiliary material; component B comprising a second main material and a second auxiliary material;

[0027] Both the first major ingredient and the second major ingredient comprise the following components: 100 parts by weight of vinyl silicone oil, 900 parts by weight of thermally conductive filler, 100 parts by weight of wave-absorbing material;

[0028] The first auxiliary material comprises the hydrogen-containing silicone oil of 20 parts by weight;

[0029] The second auxiliary material comprises the platinum catalyst of 0.1 weight part and the inhibitor of 0.001 weight part;

[0030] The absorbing material includes ferrite, and the particle size of ferrite is equal to 40 μm;

[0031] The viscosity of vinyl silicone oil is 500Pa·S;

[0032] The thermally conductive filler includes hydrophobic alumina, and t...

Embodiment 2

[0041] A high thermal conductivity gap-filling interface material as described in Embodiment 1, this embodiment has the following differences:

[0042] Both the first main ingredient and the second main ingredient include the following components: 100 parts by weight of vinyl silicone oil, 900 parts by weight of thermally conductive filler, 100 parts by weight of wave-absorbing material; Methyl hydrogen silicone oil.

[0043] A method for preparing a high thermal conductivity interstitial interface material, comprising the following steps:

[0044] Step 1: Preparation of Component A: Add vinyl silicone oil with a viscosity of 500 Pa·S, methyl hydrogen silicone oil with a hydrogen content of 0.15%, hydrophobic alumina, and ferrite to the planetary machine in order to form materials. The mixing temperature is 25°C, and the mixing time is 30 minutes; then the temperature of the material is raised to 120°C and mixed for 2 hours, and then the delowering is carried out under a vacu...

Embodiment 3

[0048] A high thermal conductivity gap-filling interface material as described in Embodiments 1 and 2, this embodiment has the following differences:

[0049] Both the first main ingredient and the second main ingredient include the following components: 100 parts by weight of vinyl silicone oil, 850 parts by weight of thermally conductive filler, and 150 parts by weight of wave-absorbing material.

[0050] A method for preparing a high thermal conductivity interstitial interface material, comprising the following steps:

[0051] Step 1: Preparation of component A: respectively add vinyl silicone oil with a viscosity of 500 Pa·S, methyl hydrogen silicone oil with a hydrogen content of 0.1%, hydrophobic alumina, and ferrite into the planetary machine in order to form materials. The mixing temperature is 25°C, and the mixing time is 30 minutes; then the temperature of the material is raised to 120°C and mixed for 2 hours, and then the delowering is carried out under a vacuum deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com