An electromagnetic shielding sealing product and its manufacturing process

An electromagnetic shielding and manufacturing process technology, applied in the field of electromagnetic shielding sealing products and their manufacturing processes, can solve the problems of affecting the shielding effect, poor shielding efficiency, poor assembly, etc., and achieve good electromagnetic shielding performance, high production efficiency, good elasticity and The effect of electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

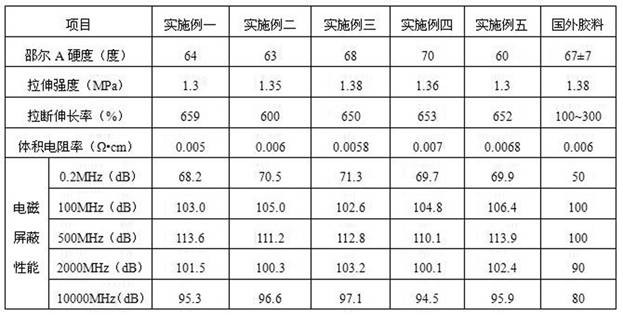

Examples

Embodiment 1

[0020]The manufacturing process of an electromagnetic shielding sealing product of the present invention includes the following steps:

[0021]1) Weigh the raw materials according to the following parts by weight: 100 parts of methyl vinyl silicone rubber, 300 parts of silver-plated glass balls, 4 parts of DCBP paste, 4 parts of coupling agent;

[0022]2) Take methyl vinyl silicone rubber, add DCBP paste, and mix in an open mill to prepare silicone rubber compound;

[0023]3) Adjust the open mill to the proper roll distance, the raw rubber wrapped rolls, adjust the baffle to keep a proper amount of excess rubber on the rolls, slowly add the silver-plated glass balls, and continue to pour the rubber back and mix until the color of the rubber is uniform and the preparation is in the initial stage. Gum;

[0024]4) The above-mentioned initial rubber material is re-melted, sliced, and cut (adjust the width of the cut according to the product requirements) to produce semi-finished products;

[0025]5) T...

Embodiment 2

[0029]1) Weigh the raw materials according to the following parts by weight: 80 parts of methyl vinyl silicone rubber, 250 parts of silver-plated conductive powder, 2 parts of DCBP paste, 2 parts of coupling agent, 2,4-dichlorobenzoyl in the DCBP paste The content is 30%, and the particle size of the silver-plated conductive powder is 50nm;

[0030]2) Take the silicone rubber, add DCBP paste, and mix it in an open mill. After mixing, leave it at room temperature for 2 hours to prepare the silicone rubber compound;

[0031]3) Adjust the open mill to the proper roll distance, the raw rubber wrapped roll, adjust the baffle to keep a proper amount of excess rubber on the roll, slowly add the silver-plated conductive powder, and continue to pour the rubber back and mix until the color of the rubber is uniform and the preparation is in the initial stage. Gum;

[0032]4) The above-mentioned initial rubber material is re-melted, sliced, and cut (adjust the width of the cut according to the product r...

Embodiment 3

[0037]1) Weigh the raw materials according to the following parts by weight: 90 parts of methyl vinyl silicone rubber, 260 parts of silver-plated aluminum powder, 8 parts of DCBP paste, 8 parts of vinyl triethoxysilane coupling agent, silver-plated aluminum powder The content is 40%, and the particle size of silver-plated aluminum powder is 100nm;

[0038]2) Take methyl vinyl silicone rubber, turn on the open mill, control the roller temperature to 40℃, add DCBP paste after the roller is wrapped, mix, after mixing, park at room temperature for 6 hours to prepare the silicone rubber compound;

[0039]3) Adjust the open mill to a proper roll distance, roll the raw rubber, adjust the baffle to keep a proper amount of remaining rubber on the roll, slowly add silver-plated aluminum powder, control the temperature at 40 ℃, and continue to pour the rubber back and mix until the rubber compound The color is uniform, and the initial rubber compound is prepared;

[0040]4) The above-mentioned initial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com