Mass polyvinyl chloride production technique

A polyvinyl chloride, production process technology, applied in the field of vinyl chloride polymerization reaction process, can solve the problems of many batches of pressure fluctuations, low rate of high-grade products, high rate of B-grade products, etc., to reduce the rate of B-grade products, improve Effect of thermal stability and stable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) After the pre-polymerization tank completes the vacuum replacement, the liquid vinyl chloride monomer is transported into the pre-polymerization tank with a monomer pump. The temperature is as high as 68°C, and the pressure is 1.2MPa, and the pre-polymerization reaction is carried out, and the "seed" is obtained after 15 minutes of reaction.

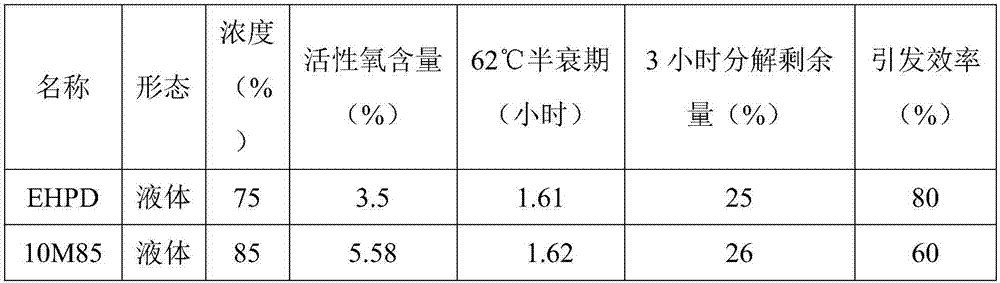

[0040] (2) Add 3000g of polymerization aid antioxidant 2,6-di-tert-butyl-p-cresol and 200g of polymerization aid thickener crotonic acid, ethyl acetate copolymer and 2L of nitric acid solution with a mass concentration of 20% In the polymerization kettle, and vacuum replace the polymerization kettle; then add 15t of vinyl chloride monomer to the polymerization kettle, and add the "seed" obtained in step (1), and then add the initiator 10M85 with 0.03% of the total mass of vinyl chloride monomer and 0.007% initiator 701M70, then pass hot water at 80°C into the interlayer of the polymerization kettle shell to heat the mixed mate...

Embodiment 2

[0043] (1) After the pre-polymerization tank completes the vacuum replacement, the liquid vinyl chloride monomer is transported into the pre-polymerization tank with a monomer pump. The temperature is as high as 68°C, and the pressure is 1.2MPa, and the pre-polymerization reaction is carried out, and the "seed" is obtained after 15 minutes of reaction.

[0044] (2) 2800g polymerization aid antioxidant 2,6-di-tert-butyl p-cresol and 186g polymerization aid thickener crotonic acid, ethyl acetate copolymer and 1.8L mass concentration are 20% nitric acid solution together Put into the polymerization kettle, and vacuum replace the polymerization kettle; then add 14.5t vinyl chloride monomer to the polymerization kettle, and add the "seed" obtained in step (1), and then add 0.03% of the total mass of vinyl chloride monomer to initiate Agent 10M85 and 0.007% initiator 701M70, and then pass hot water at 80°C into the interlayer of the polymerization kettle shell to heat the mixed mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com