Synthetic method of artificial cytomembrane main ingredient 2-methacryloyloxy ethyl phosphorylcholine

A technology of methacryloyloxyethylphosphorylcholine and synthesis method, which is applied in the field of synthesis of 2-methacryloyloxyethylphosphorylcholine, the main component of artificial cell membranes, and can solve the problem of being unable to provide long-term stable products Problems such as supply, long synthetic route, cumbersome operation, etc., achieve the effect of reducing the types of reaction raw materials, low price, and simplifying the synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

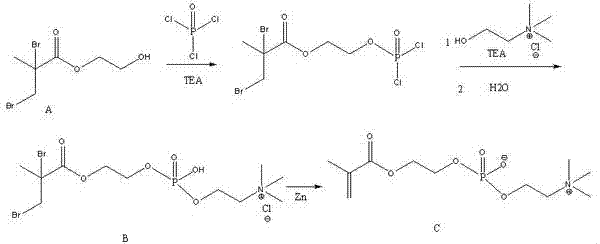

[0029] A method for synthesizing 2-methacryloyloxyethyl phosphorylcholine, the main component of an artificial cell membrane, comprising the steps of:

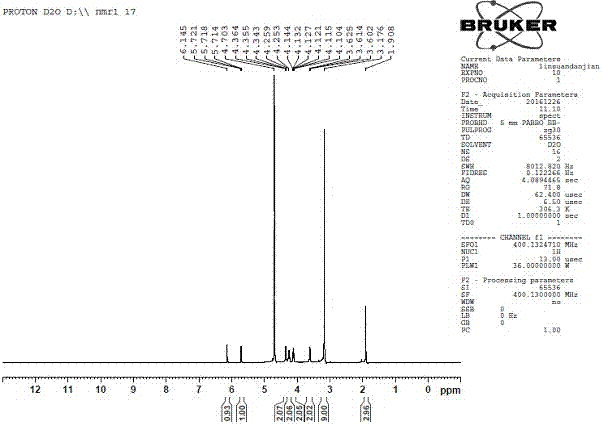

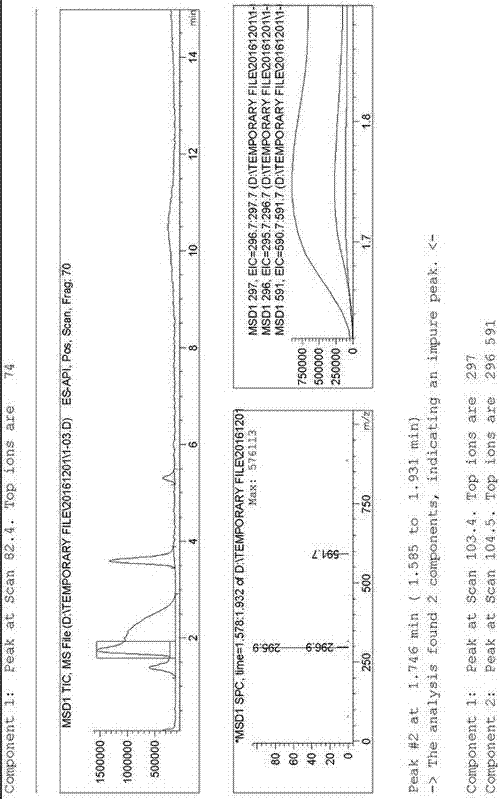

[0030] Step 1) In a 500 ml round bottom flask, dissolve 15.3 g of phosphorus oxychloride in 300 ml of dry acetonitrile, and lower the temperature of the reaction solution to -5°C. Then 10.1 g of triethylamine was added to the reaction system. Add 29 grams of 2,3-dibromo-2-methylpropionate hydroxyethyl ester dropwise, keeping the temperature below 0°C during the dropwise addition. After the dropwise addition, the mixture was stirred at 0° C. for 2 hours, slowly raised to room temperature, and stirred for another half an hour. Then the reaction solution was cooled to 0°C, 10.1 g of triethylamine was added, and 14 g of choline chloride was added in batches. The mixture was slowly raised to room temperature and stirred for 2 hours. TLC traced the disappearance of the starting material. The reaction liquid was cooled to 0° C. ag...

Embodiment 2

[0037] A method for synthesizing 2-methacryloyloxyethyl phosphorylcholine, the main component of an artificial cell membrane, comprising the steps of:

[0038] Step 1) In a 500 ml round bottom flask, dissolve 15.3 g of phosphorus oxychloride in 300 ml of dry acetonitrile, and lower the temperature of the reaction solution to -5°C. Then 10.1 g of triethylamine was added to the reaction system. Add 32 grams of 2,3-dibromo-2-methylpropionate hydroxyethyl ester dropwise, keeping the temperature below 0°C during the dropwise addition. After the dropwise addition, the mixture was stirred at 0° C. for 2 hours, slowly raised to room temperature, and stirred for another half an hour. Then the reaction solution was cooled to 0°C, 10.1 g of triethylamine was added, and 14 g of choline chloride was added in batches. The mixture was slowly raised to room temperature and stirred for 2 hours. TLC traced the disappearance of the starting material. The reaction liquid was cooled to 0° C. ag...

Embodiment 3

[0041] A method for synthesizing 2-methacryloyloxyethyl phosphorylcholine, the main component of an artificial cell membrane, comprising the steps of:

[0042]Step 1) In a 500 ml round bottom flask, dissolve 15.3 g of phosphorus oxychloride in 300 ml of dry acetonitrile, and lower the temperature of the reaction solution to -5°C. Then 10.1 g of triethylamine was added to the reaction system. Add 29 grams of 2,3-dibromo-2-methylpropionate hydroxyethyl ester dropwise, keeping the temperature below 0°C during the dropwise addition. After the dropwise addition, the mixture was stirred at 0° C. for 2 hours, slowly raised to room temperature, and stirred for another half an hour. Then the reaction solution was cooled to 0°C, 10.1 g of triethylamine was added, and 15 g of choline chloride was added in batches. The mixture was slowly raised to room temperature and stirred for 2 hours. TLC traced the disappearance of the starting material. The reaction liquid was cooled to 0° C. aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com