A kind of hexagonal sintered permanent ferrite magnet and preparation method thereof

A technology of permanent ferrite and hexagonal crystal, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of poor intrinsic coercive force and magnetic properties, and reduce stacking faults problem, reduction of production cost, effect of reduction in dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

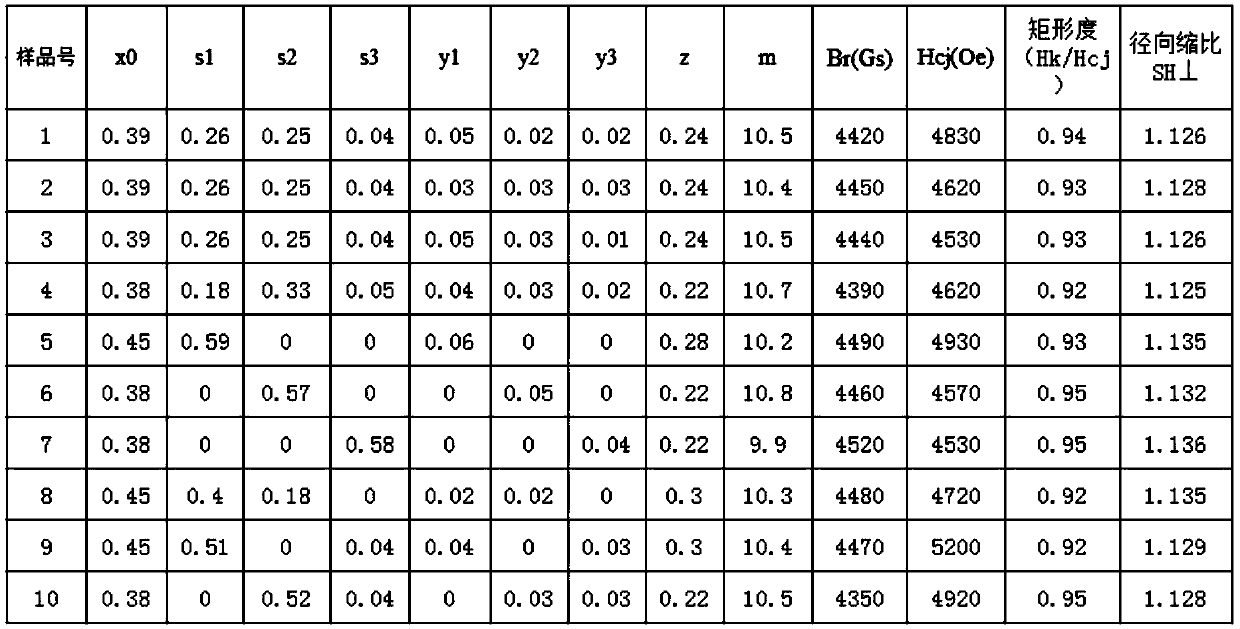

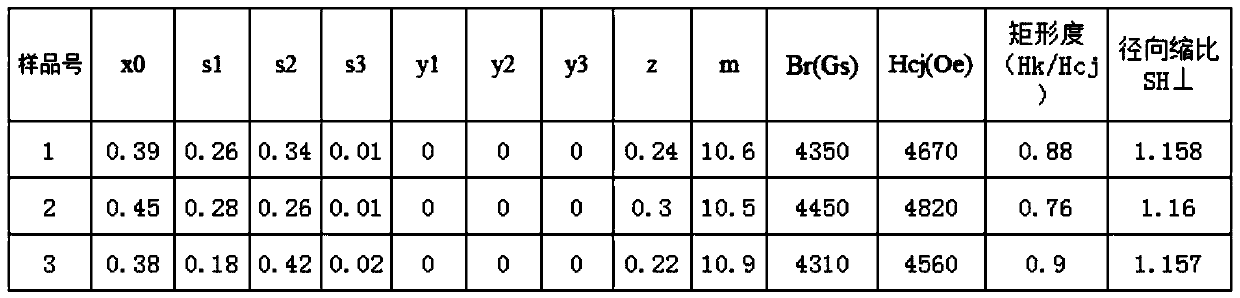

Examples

Embodiment 1

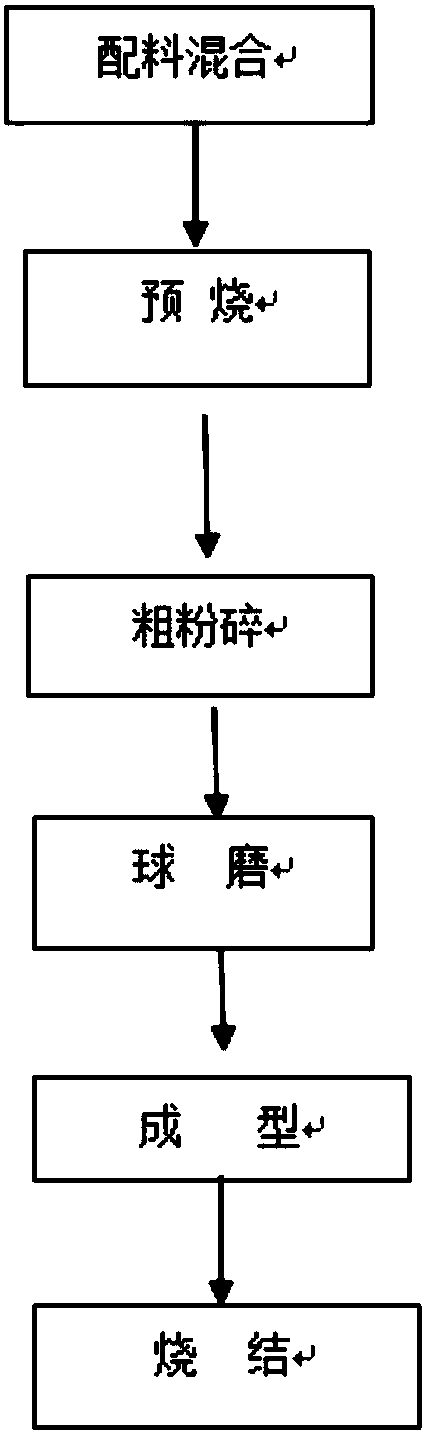

[0041] A kind of hexagonal crystal type sintered permanent ferrite magnet of the present embodiment, its composition formula uses A 2+ 1-x-y B 1+ y La 3+ x Fe 3+ n- z co 2+ z o 2- 19 Indicates that A is a mixture of divalent alkaline earth metals calcium, strontium, and barium, B is a mixture of monovalent alkali metals lithium, sodium, and potassium, and x, y, z, and n are the addition ratios of each element, where x is 0.24-0.45 , y is 0.03-0.10, z is 0.20-0.33, n is 10.0-12.0, and 1.1z≤x≤1.8z, y+z≤x. Such as figure 1 Shown, its preparation method comprises the following steps:

[0042] Step 1. Ingredients mixing: press A 2+ 1-x-y B 1+ y La 3+ x Fe 3+ n-z co 2+ z o 2- 19 The composition formula weighs and calculates the raw material powder containing the required elements, and mixes the raw materials uniformly through a wet process for 1 hour. The average particle size of the mixed material after mixing reaches 0.6um, and the reactivity is better, wh...

Embodiment 2

[0052] A kind of hexagonal crystal type sintered permanent ferrite magnet of the present embodiment, its composition formula uses A 2+ 1-x-y B 1+ y La 3+ x Fe 3+ n- z co 2+ z o 2- 19 Indicates that A is divalent alkaline earth metal calcium, B is monovalent alkali metal lithium, and x, y, z, n are the addition ratios of each element, where x is 0.24-0.45, y is 0.03-0.10, and z is 0.20-0.33 , n is 10.0-12.0, and 1.1z≤x≤1.8z, y+z≤x. Its preparation method is basically the same as Example 1, and the difference is that the raw material ingredients and processing method of the present embodiment are slightly different, as follows:

[0053] Raw material powder is iron oxide (Fe 2 o 3 ) powder, calcium carbonate (CaCO 3 ) powder, lanthanum oxide (La 2 o 3 ) powder, cobalt oxide (Co 2 o 3 ) powder, lithium carbonate (Li 2 CO 3 ) powder; also add an additive as follows: 0.5wt% SiO 2 Powder, 0.2wt% H 3 BO 3 Powder, 0.5wt% lithium chloride, 0.5wt% calcium chloride...

Embodiment 3

[0061] A kind of hexagonal crystal type sintered permanent ferrite magnet of the present embodiment, its composition formula uses A 2+ 1-x-y B 1+ y La 3+ x Fe 3+ n- z co 2+ z o 2- 19 Indicates that A is the divalent alkaline earth metal strontium, B is the monovalent alkali metal sodium, and x, y, z, n are the addition ratios of each element, where x is 0.24-0.45, y is 0.03-0.10, and z is 0.20-0.33 , n is 10.0-12.0, and 1.1z≤x≤1.8z, y+z≤x. Its preparation method is basically the same as Example 1, and the difference is that the raw material ingredients and processing method of the present embodiment are slightly different, as follows:

[0062] Raw material powder is iron oxide (Fe 2 o 3 ) powder, strontium carbonate (SrCO 3 ) powder, lanthanum oxide (La 2 o 3 ) powder, cobalt oxide (Co 2 o 3 ) powder, sodium carbonate (Na 2 CO 3 ) powder, also added with an additive as follows: 0.3wt% sodium chloride, 0.3wt% strontium chloride. The above-mentioned ingredi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com