Modified asphalt mixture

A technology of modified asphalt and mixture, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of poor adhesion and inability to store for a long time, and achieve the effects of low cost, stable physical and chemical properties, and convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] 1. Ratio preparation

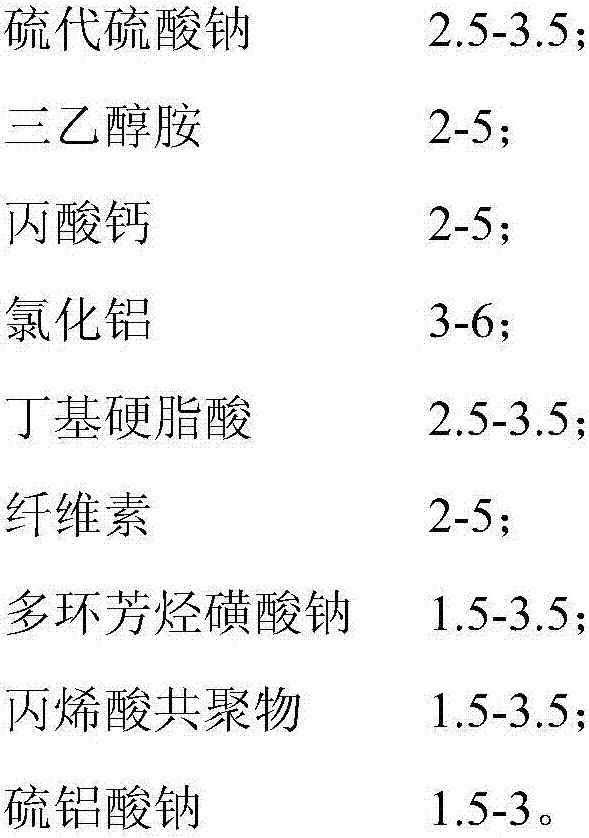

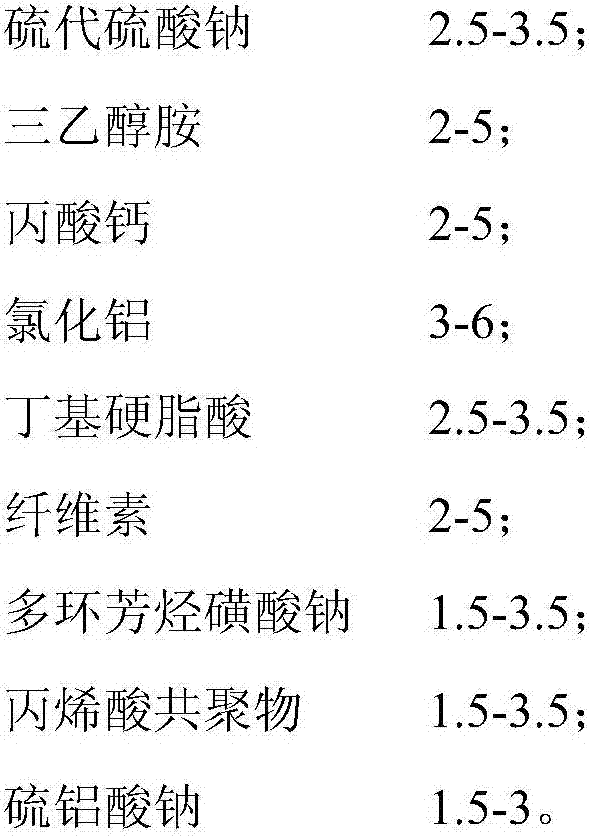

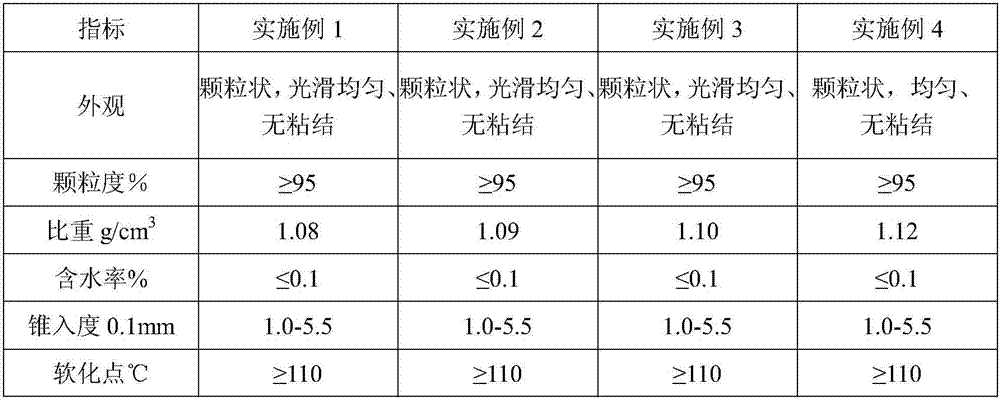

[0088] The modified basic material, the first additive and the second additive are prepared according to the following weight ratio: high-quality asphalt 55; natural rubber latex 11; synthetic rubber 11; sodium thiosulfate 3.5; triethanolamine 5; calcium propionate 2; Aluminum 3; Butyl stearic acid 3.5; Cellulose 2; Sodium polycyclic aromatic hydrocarbon sulfonate 1.5; Acrylic acid copolymer 3.5; Sodium sulfoaluminate 3; Sodium lignosulfonate 3; Resin 3;

[0089] 2. Preheating treatment

[0090] The weighed high-quality asphalt, natural rubber latex, synthetic rubber, sodium thiosulfate, triethanolamine, calcium propionate, aluminum chloride, cellulose, polycyclic aromatic hydrocarbon sodium sulfonate, acrylic acid copolymer, sodium sulfoaluminate , Butyl stearic acid is added to the pre-heating reactor, and the temperature of the pre-heating reactor is heated for 30 minutes, so that the temperature of the material in the reactor reaches 175-180 ...

Embodiment 2

[0096] 1. Ratio preparation

[0097] The modified basic material, the first additive and the second additive are prepared according to the following weight ratio: high-quality asphalt 85; natural rubber latex 8; synthetic rubber 8; sodium thiosulfate 2.5; triethanolamine 2; calcium propionate 2; Aluminum 6; Butyl stearic acid 2.5; Cellulose 5; Sodium polycyclic aromatic hydrocarbon sulfonate 3.5; Acrylic acid copolymer 1.5; Sodium sulfoaluminate 1.5; Sodium lignosulfonate 6; Resin 6; Carbon black 0.5.

[0098] 2. Preheating treatment

[0099] The weighed high-quality asphalt, natural rubber latex, synthetic rubber, sodium thiosulfate, triethanolamine, calcium propionate, aluminum chloride, cellulose, polycyclic aromatic hydrocarbon sodium sulfonate, acrylic acid copolymer, sodium sulfoaluminate , Butyl stearic acid is added to the pre-heating reactor, and the temperature of the pre-heating reactor is heated for 30 minutes, so that the temperature of the material in the reacto...

Embodiment 3

[0105] 1. Ratio preparation

[0106] The modified basic material, the first additive and the second additive are prepared according to the following weight ratio: high-quality asphalt 62; natural rubber latex 9; synthetic rubber 10; sodium thiosulfate 3; triethanolamine 3; calcium propionate 3; Aluminum 4; Butyl stearic acid 3; Cellulose 3; Sodium polycyclic aromatic hydrocarbon sulfonate 1.9; Acrylic acid copolymer 2.2; Sodium sulfoaluminate 2.3; Sodium lignosulfonate 4.1; Resin 5.2; Carbon black 0.9.

[0107] 2. Preheating treatment

[0108] The weighed high-quality asphalt, natural rubber latex, synthetic rubber, sodium thiosulfate, triethanolamine, calcium propionate, aluminum chloride, cellulose, polycyclic aromatic hydrocarbon sodium sulfonate, acrylic acid copolymer, sodium sulfoaluminate , Butyl stearic acid is added to the pre-heating reactor, and the temperature of the pre-heating reactor is heated for 25 minutes, so that the temperature of the material in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com