A kind of modified chitosan-silicon dioxide composite airgel material and its preparation method and application

A composite airgel and silica technology, which is applied in the field of textile finishing, can solve the problems of easy adsorption, good oil adsorption performance, and easy dirt of jacket fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a modified chitosan-silicon dioxide composite airgel material, which is prepared through the following steps:

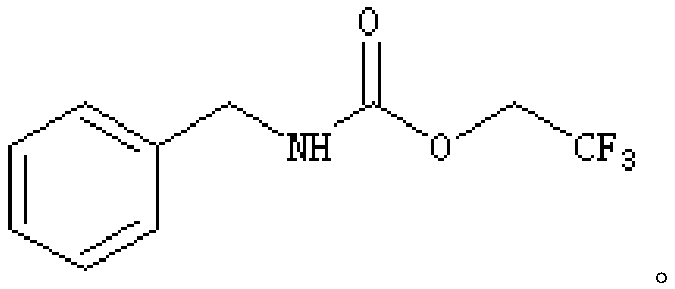

[0039] (1) Add 100g of trifluoroethanol, 96g of carbonic acid, and 19.6g of sulfuric acid into a 500ml three-necked flask, stir and heat to reflux, keep the temperature at 60°C, react for 10h, filter, and then add 200ml of cyclohexane to the filtrate Extraction. After extraction, add 10.2 g of acetic anhydride to the upper layer solution, stir and heat to reflux at 80° C. for 8 hours, and then distill to obtain white crystalline solid A.

[0040] (2) Add 270g of solid A, 108.16g of benzylamine, and 500ml of ethyl acetate into a 1000ml three-necked flask, heat, stir and reflux at 60°C for 5h, then distill at 80°C to obtain pale yellow needle-like solid B.

[0041] (3) Solid B was roasted at 200°C for 1 hour to obtain solid C, which is the airgel modification additive. The NMR data are as follows:

[0042] 1 H-NMR (400Hz) δ (ppm) ...

Embodiment 2

[0047] The present embodiment provides a chitosan-silicon dioxide composite airgel material, which is prepared through the following steps:

[0048] (1) Add 100 g of trifluoroethanol, 100 g of carbonic acid, and 20 g of sulfuric acid into a 500 ml three-neck flask, stir and heat to reflux, keep the temperature at 65° C., and filter after 12 hours of reaction, then add 200 ml of cyclohexane to the filtrate for extraction. After extraction, 10.5 g of acetic anhydride was added to the upper layer solution, stirred and heated to reflux at 85°C for 10 h, and then distilled to obtain white crystalline solid A.

[0049] (2) Add 280g of solid A, 110g of benzylamine, and 500ml of ethyl acetate into a 1000ml three-neck flask, heat, stir and reflux at 65°C for 5h, then distill at 85°C to obtain light yellow needle-like solid B.

[0050] (3) Calcining solid B at 210° C. for 1 h to obtain solid C, which is the airgel modification aid.

[0051] (4) Heat and stir 95g tetraethyl orthosilicat...

Embodiment 3

[0055] The present embodiment provides a chitosan-silicon dioxide composite airgel material, which is prepared through the following steps:

[0056] (1) Add 100g of trifluoroethanol, 90g of carbonic acid, and 19g of sulfuric acid into a 500ml three-necked flask, stir and heat to reflux, keep the temperature at 60°C, react for 8h, filter, then add 200ml of cyclohexane to the filtrate for extraction, After extraction, 10 g of acetic anhydride was added to the upper layer solution, stirred and heated to reflux at 80° C. for 8 h, and then distilled to obtain white crystalline solid A.

[0057] (2) Add 270g of solid A, 105g of benzylamine, and 500ml of ethyl acetate into a 1000ml three-neck flask, heat, stir and reflux at 60°C for 5h, then distill at 80°C to obtain light yellow needle-like solid B.

[0058] (3) Calcining solid B at 190° C. for 1 h to obtain solid C, which is the airgel modification aid.

[0059] (4) Take 92g tetraethyl orthosilicate, 28g chitosan, 4.5g citric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com