Hygroscopic superfine fiber leather and its manufacturing method

A microfiber leather and a manufacturing method technology, applied in the field of clothing materials, can solve the problems of easy sweating, affecting the quality of clothing materials, easy to wrinkle, etc., and achieve excellent elongation recovery, excellent thermal performance, and high elastic recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

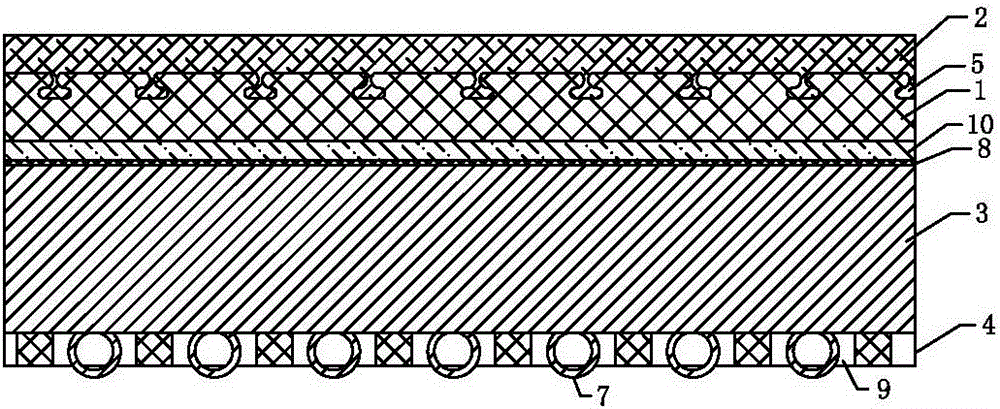

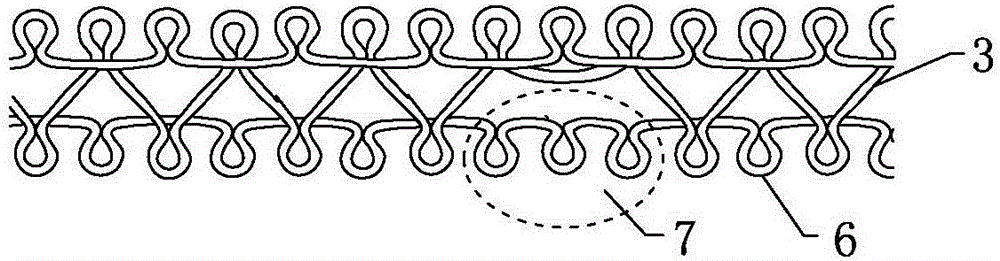

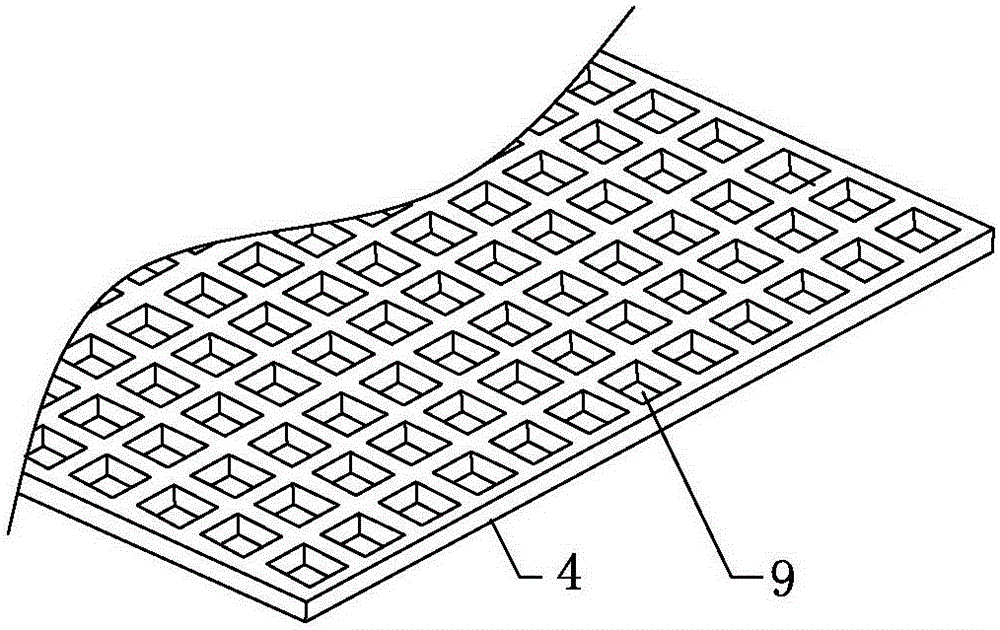

[0036] Hygroscopic microfiber leather such as Figure 1 to Figure 3 As shown, it includes a dyed layer 1, a composite membrane 2 coated on the upper surface of the dyed layer 1, a base layer 3 arranged on the lower surface of the dyed layer 1, and an anti-wrinkle mesh layer 4 arranged on the lower surface of the base layer 3. The composite membrane 2 is made of polyester Made of tetrafluoroethylene (PTFE) film coated with a layer of polyurethane (PU) film. The lower surface of the dyed layer 1 is coated with a layer of water-repellent layer 10 . The dyed layer 1 is made of superfiber material, the upper surface of the dyed layer 1 is uneven, the upper surface of the dyed layer 1 is provided with a groove 5, and the cross-sectional area of the lower part of the groove 5 is larger than the cross-sectional area of the upper part of the groove 5. The base layer 3 is made of spandex yarn, and the spandex yarn forms several coils 6 on the lower surface, and more than two contin...

Embodiment 2

[0040] The manufacture method of hygroscopic microfiber leather comprises the following steps:

[0041] a. Dyeing the dyed layer 1;

[0042] The dyeing process adopts Italian Bazzoni environmental protection O-type low-tension dyeing machine. The dyeing machine enters the water and divides into the cloth at room temperature, and adds CD-1000N, stirs it in the auxiliary cylinder of the dyeing machine and opens an automatic feeding system, which will automatically Pump into the dyeing machine, the pH value in the dyeing machine is controlled between 3-6; then enter the process parameters in the computer system: tension 20N, speed 150m / min, nozzle pressure 0.21MP / cm 2 , the speed of the main pump is 1005r / min, the bath ratio is 1:5, the pretreatment temperature is 98°C, the heating rate is 2°C / min, and the holding time is 20min; CD-1000N; heat up to the post-treatment temperature of 50°C at a rate of 2°C / min, and hold for 20 minutes. Input the above process parameters into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com