Wall-mounted panel

A technology for hanging boards and walls, applied in covering/lining, building, building structure, etc., can solve the problems of poor energy saving effect, achieve the effect of ensuring thermal performance and reducing energy consumption in life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

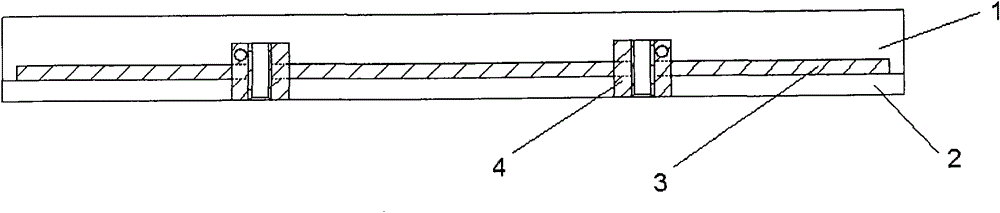

[0039] The preparation method of the wall hanging board is not particularly limited. For example, the materials of the hygroscopic surface layer 1 and the waterproof bottom layer 2 can be added to the mold respectively, and the hanging board skeleton 3 is set and solidified. The hanging board skeleton 3 It is arranged in the hygroscopic surface layer 1 or the waterproof bottom layer 2, or is arranged between the hygroscopic surface layer 1 and the waterproof bottom layer 2.

[0040] The materials and contents of the hygroscopic surface layer 1 , the waterproof bottom layer 2 and the hanging board skeleton 3 have been described above, and will not be repeated here.

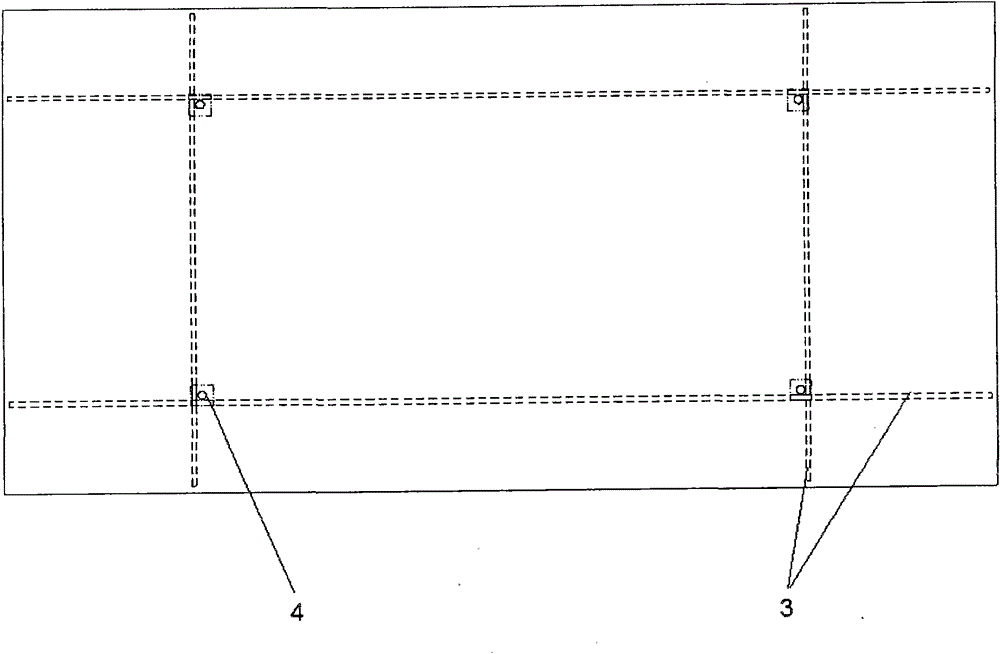

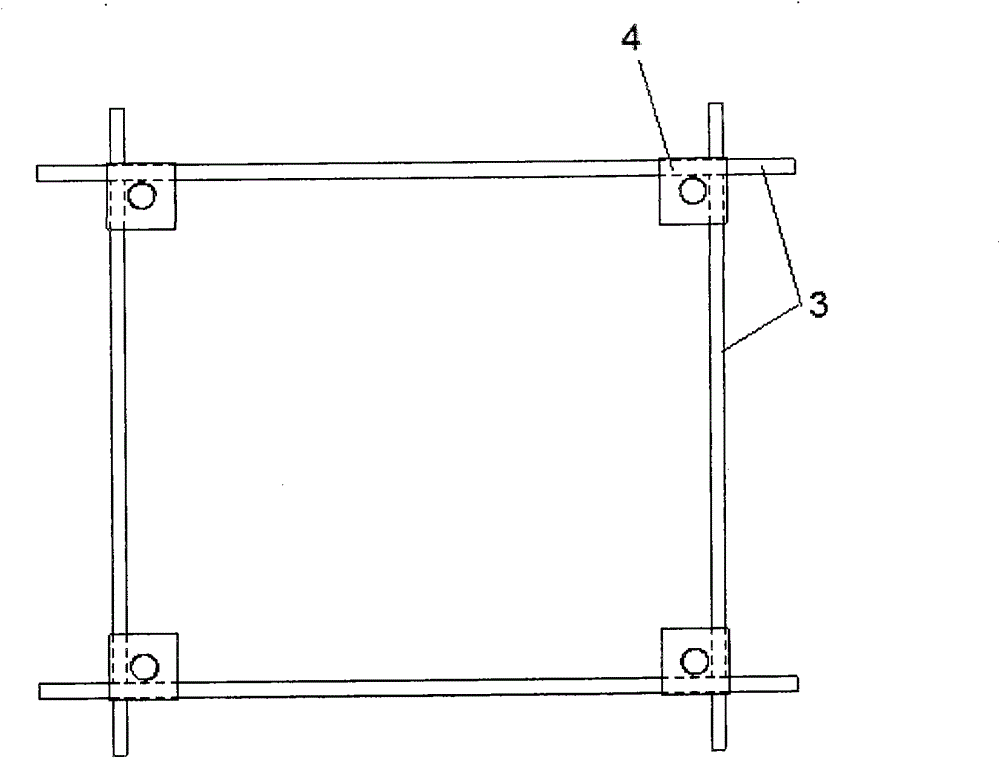

[0041] According to the present invention, there is no particular limitation on the setting method of the hanging board skeleton 3 , preferably, the hanging board skeleton 3 is uniformly arranged in the hygroscopic surface layer 1 or in the waterproof bottom layer 2 , or evenly arranged between the hygroscopic surf...

Embodiment 1

[0046] This embodiment is used to illustrate the wall hanging board provided by the present invention.

[0047] (1) Mix 100 parts by weight of silica sand (average particle diameter of 500 μm) and 6 parts by weight of epoxy resin binder (Guangzhou Sika Building Materials Co., Ltd., Sika 731) to obtain a hygroscopic surface layer material.

[0048] (2) 100 parts by weight of waterproof sand (Beijing Renchuang Technology Group Co., Ltd., STS-303, the average particle diameter is 120 μm), 3 parts by weight of perlite (average particle diameter is 2mm), 25 parts by weight of cement ( Lafarge, 425#) mixed evenly to obtain the material for the waterproof bottom layer.

[0049] (3) Add the material for the hygroscopic surface layer obtained in step (1) into a steel mold with a size of 30 × 60 × 3 centimeters, after that, set the "well"-shaped hanging board skeleton (with a diameter of 4mm, cold-drawn steel bars ), and then add the material for the waterproof base layer obtained in s...

Embodiment 2

[0052] This embodiment is used to illustrate the wall hanging board provided by the present invention.

[0053] (1) Mix 100 parts by weight of silica sand (average particle diameter of 80 μm) and 25 parts by weight of epoxy resin binder (Guangzhou Sika Building Materials Co., Ltd., Sika 731) to obtain a hygroscopic surface layer material.

[0054] (2) 100 parts by weight of waterproof sand (Beijing Renchuang Technology Group Co., Ltd., STS-303, the average particle diameter is 100 μm), 15 parts by weight of ceramsite (average particle diameter is 10mm), 35 parts by weight of cement ( Lafarge, 425#) mixed evenly to obtain the material for the waterproof bottom layer.

[0055] (3) Add the material for the hygroscopic surface layer obtained in step (1) into a steel mold with a size of 30 × 60 × 3 centimeters, after that, set the "well"-shaped hanging board skeleton (with a diameter of 4mm, cold-drawn steel bars ), and then add the material for the waterproof bottom layer obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com