Blend material-enveloped slow release fertilizer special for spinaches and preparation method of slow release fertilizer

A technology of material package and slow-release fertilizer, applied in application, nitrogen fertilizer, phosphate fertilizer, etc., can solve the problems of difficult treatment, secondary pollution, large quantity, etc., achieve the effects of reducing toxicity and solubility, increasing heavy metal content, and improving the planting environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

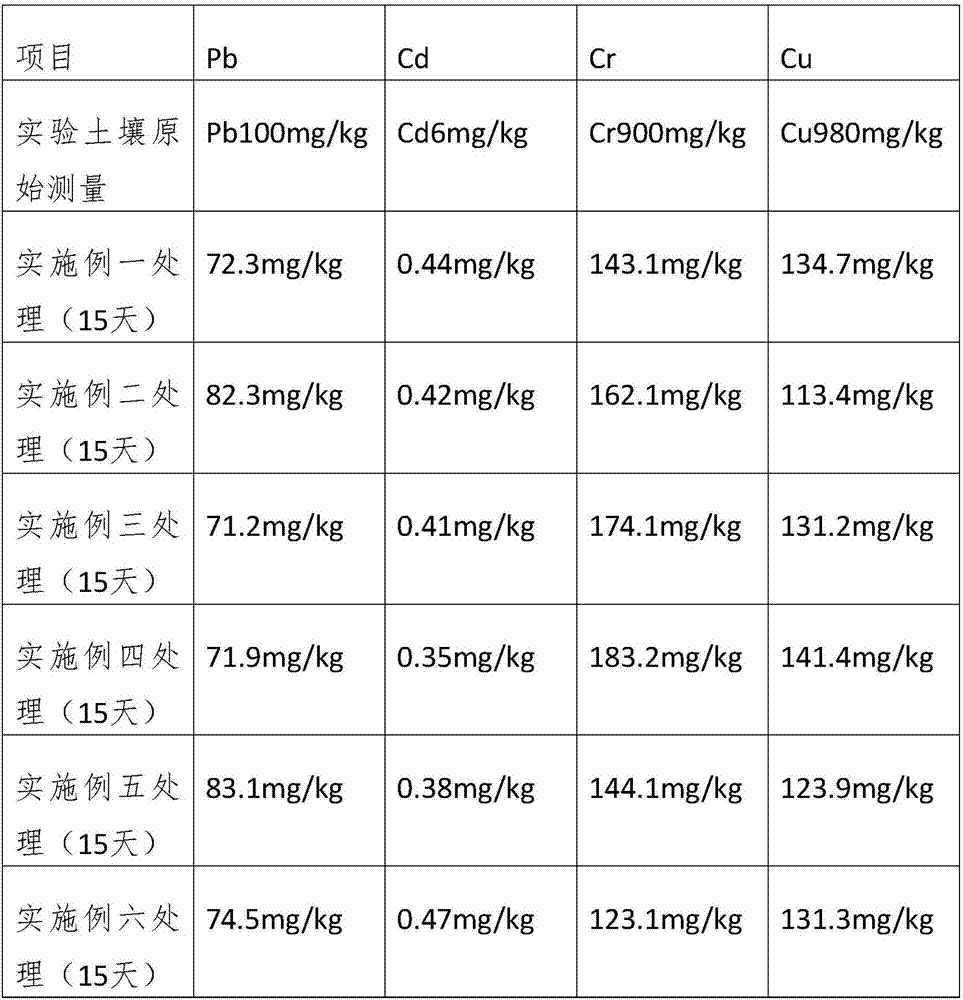

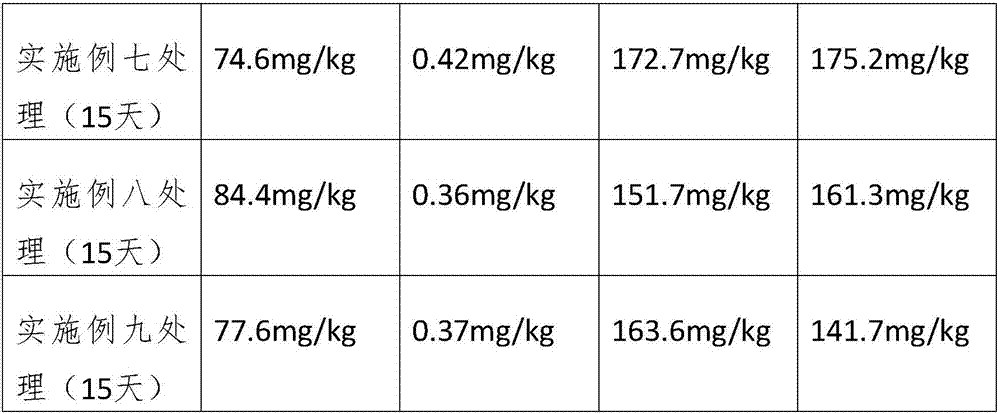

Examples

Embodiment 1

[0022] Formula: 17 parts of ammonium metaphosphate, 10 parts of ammonium sulfate, 45 parts of urea, 4 parts of superphosphate, 21 parts of potassium dihydrogen phosphate, 6 parts of admixture, 13 parts of reaction aid, 20 parts of modified montmorillonite, poly Lactic acid 55 parts, polyvinyl alcohol 50 parts.

[0023] The preparation method of modified montmorillonite:

[0024] (1) Pulverization: the montmorillonite is ball-milled into a fine powder with a fineness≤0.04mm with a ball mill to obtain montmorillonite powder;

[0025] (2) Activation: Put the montmorillonite powder into the ultrasonic equipment, process it at an ultrasonic power of 600w for 20min, then send it into the calcination tower for 90min at a high temperature of 300°C, add the montmorillonite powder into absolute ethanol after cooling, and ultrasonically Centrifuge after dispersing for 10 minutes, repeat ultrasonic dispersion and centrifugation twice, then add distilled water, ultrasonically disperse for...

Embodiment 2

[0029] Formula: 23 parts of ammonium metaphosphate, 16 parts of ammonium sulfate, 65 parts of urea, 10 parts of superphosphate, 27 parts of potassium dihydrogen phosphate, 12 parts of admixture, 19 parts of reaction aid, 26 parts of modified montmorillonite, poly 61 parts of lactic acid, 56 parts of polyvinyl alcohol.

[0030] The preparation method of modified montmorillonite:

[0031] (1) Pulverization: the montmorillonite is ball-milled into a fine powder with a fineness≤0.04mm with a ball mill to obtain montmorillonite powder;

[0032] (2) Activation: Put the montmorillonite powder into the ultrasonic equipment, process it for 40min under the ultrasonic power of 1000w, then send it into the calcination tower and calcine at 600°C for 120min, after cooling, add the montmorillonite powder into absolute ethanol, and ultrasonically Centrifuge after dispersing for 18 minutes, repeat ultrasonic dispersion and centrifugation for 3 times, then add distilled water, ultrasonically d...

Embodiment 3

[0036] Formula: 19 parts of ammonium metaphosphate, 12 parts of ammonium sulfate, 50 parts of urea, 6 parts of superphosphate, 23 parts of potassium dihydrogen phosphate, 8 parts of admixture, 15 parts of reaction aid, 22 parts of modified montmorillonite, poly 57 parts of lactic acid, 52 parts of polyvinyl alcohol.

[0037] The preparation method of modified montmorillonite:

[0038] (1) Pulverization: the montmorillonite is ball-milled into a fine powder with a fineness≤0.04mm with a ball mill to obtain montmorillonite powder;

[0039] (2) Activation: Put the montmorillonite powder into the ultrasonic equipment, process it for 20min at an ultrasonic power of 600w, then send it into the calciner tower and calcinate it at a high temperature of 300-℃ for 90min, add the montmorillonite powder into absolute ethanol after cooling, After ultrasonic dispersion for 10 minutes, centrifuge, repeat ultrasonic dispersion and centrifugation twice, then add distilled water, ultrasonic dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com