Unfired magnesite-chrome bricks used for metallurgical non-ferrous smelting furnaces, and preparation method thereof

A technology for smelting furnaces and magnesia-chrome bricks, which is applied in non-fired magnesia-chrome bricks for non-ferrous smelting furnaces, and in the field of metallurgy, which can solve the problems of failure to meet the performance requirements of refractory materials, low compressive strength and thermal shock stability, and short furnace life and other problems, to achieve the effect of ideal bonding strength, good load softening temperature, and prolonging the life of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

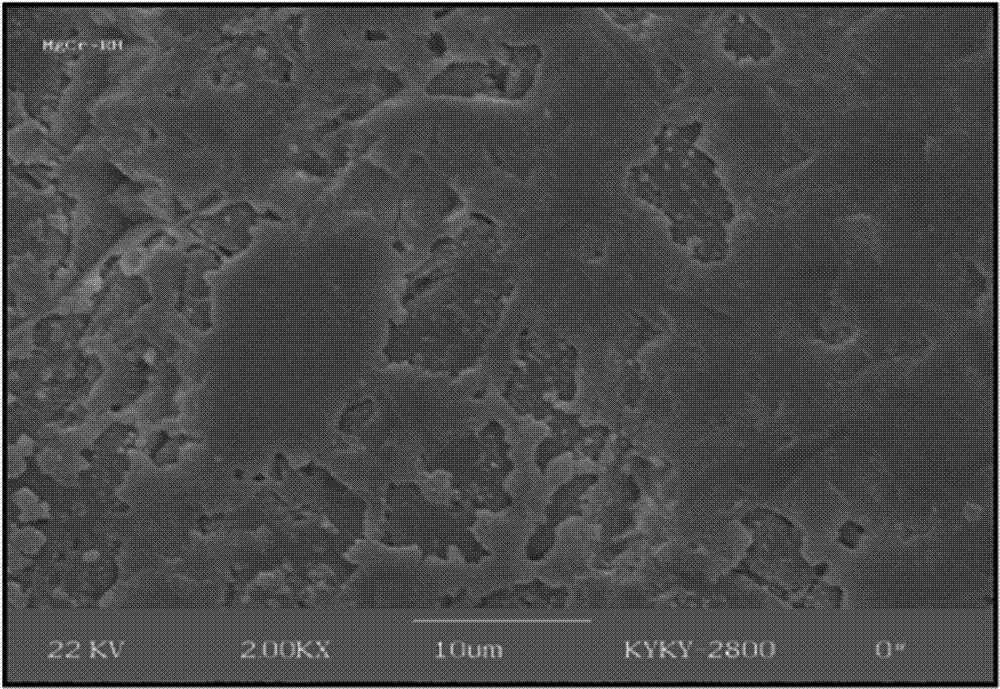

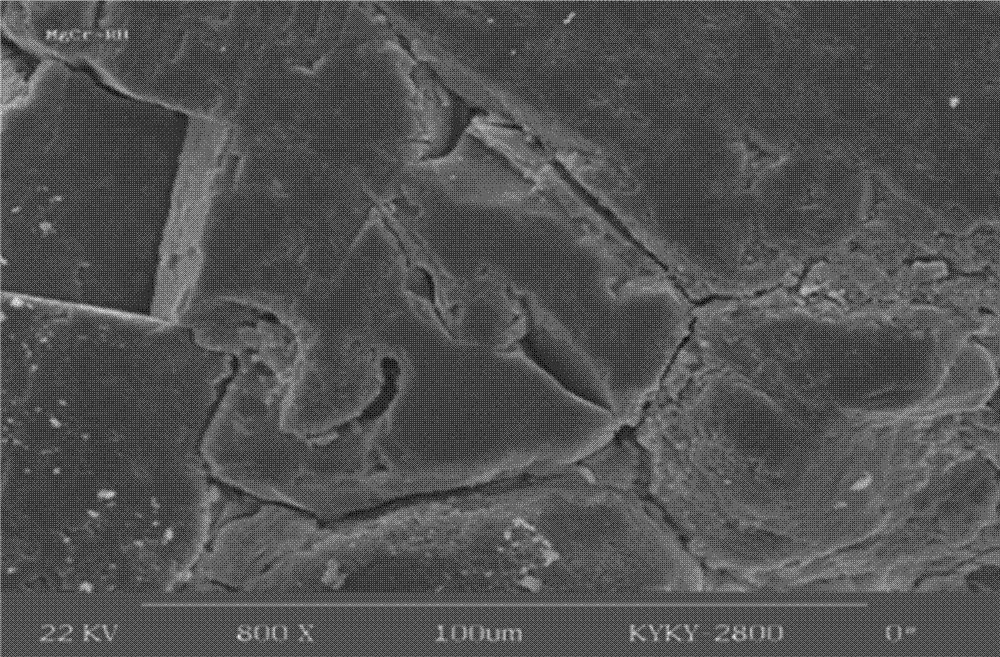

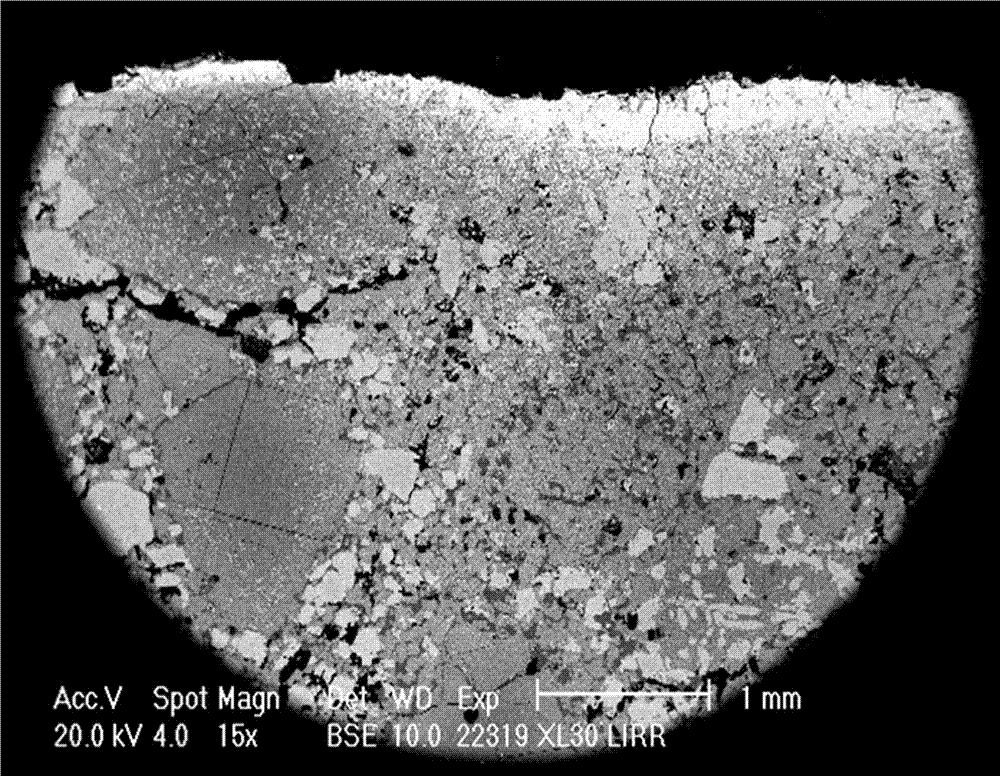

Image

Examples

Embodiment 1

[0037] The raw materials were weighed according to the components specified in Table 1 below, and the preparation method was as follows.

[0038] A method for preparing unfired magnesia-chrome bricks for metallurgical and non-ferrous smelting furnaces, the steps are as follows:

[0039] (1) Weigh high-purity magnesia and fused magnesia-chrome sand according to parts by weight, put them into a crusher for crushing, and then add them to a ball mill for crushing, and then use a vibrating screen to screen out the particle size to a particle size of 7-90 purpose aggregate;

[0040] (2) Weigh ferrochrome concentrate, cold sintering agent, rare earth oxide and activated alumina micropowder according to parts by weight, put them into a container and mix them to form a powder.

[0041] (3) Mixing: Put the prepared aggregate into the mud mixer, add vitrified binder, the rotation speed is 40-60r / min, and the stirring time is 10-20 minutes. When stirring, add water until the vitrified bi...

Embodiment 2

[0046] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 5.

Embodiment 3

[0048] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com