Graphene-doped catalyst for production of methanol by means of carbon dioxide hydrogenation

A technology of carbon dioxide and nitrogen-doped graphene, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., to achieve enhanced activity, accelerated catalytic reactions, and good contact opportunities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

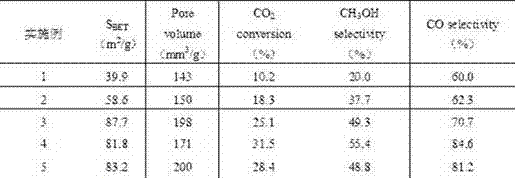

Examples

Embodiment 1

[0020] Embodiment 1: press Cu / ZnO / Al 2 o 3 =4 / 3 / 1 mass ratio, weigh Cu(NO 3 ) 2 ∙3H 2 O6.3g, Zn(NO 3 ) 2 ∙6H 2 O4.7g, Al(NO 3 ) 3 . 9H 2 O4.7g, dissolved in 54mL deionized water, weighed 10.6gNa 2 CO 3 Dissolve in 100mL deionized water, and flow in 200mL deionized water with stirring at 70°C for co-precipitation reaction, control pH = 7, continue stirring for 2h after precipitation, age at 30°C for 12h, filter, wash, vacuum overnight at 60°C Dry, pass N at 350°C 2 Calcined for 5h to obtain the catalyst.

Embodiment 2

[0021] Embodiment 2: press Cu / ZnO / Al 2 o 3 =4 / 3 / 2 mass ratio, weigh Cu(NO 3 ) 2 ∙3H 2 O6.0g, Zn(NO 3 ) 2 ∙6H 2 O4.5g, Al(NO 3 ) 3 . 9H 2 O4.5g, dissolved in 52mL deionized water, weighed 10.6gNa 2 CO 3 Dissolve in 100mL deionized water, weigh 0.16g nitrogen-doped graphene and dissolve it in 200mL deionized water, ultrasonicate for 30min, and flow the nitrate solution and precipitant together in the nitrogen-doped graphene solution under the condition of stirring at 70°C for co-precipitation Reaction, control pH = 7, continue to stir for 2 hours after the precipitation is complete, age at 30°C for 12 hours, filter, wash, dry overnight in vacuum at 60°C, pass N at 350°C 2 Calcined for 5h to obtain the catalyst.

Embodiment 3

[0022] Embodiment 3: by Cu / ZnO / Al 2 o 3 =4 / 3 / 3 mass ratio, weigh Cu(NO 3 ) 2 ∙3H 2 O5.8g, Zn(NO 3 ) 2 ∙6H 2 O4.4g, Al(NO 3 ) 3 . 9H 2 O4.4g, dissolved in 51mL deionized water, weighed 10.6gNa 2 CO 3 Dissolve in 100mL deionized water, weigh 0.28g nitrogen-doped graphene and dissolve it in 200mL deionized water, ultrasonicate for 30min, and flow the nitrate solution and precipitant together in the nitrogen-doped graphene solution under the condition of stirring at 70°C for co-precipitation Reaction, control pH = 7, continue to stir for 2 hours after the precipitation is complete, age at 30°C for 12 hours, filter, wash, dry overnight in vacuum at 60°C, pass N at 350°C 2 Calcined for 5h to obtain the catalyst. The solvent for dissolving and dispersing the nitrogen-doped graphene is a mixed solution of deionized deionized water and ethanol, and the surfactant polyvinylpyrrolidone PVP is added to facilitate dissolution by ultrasound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com