High-efficiency composite dephosphorization agent and preparation method thereof

A compound phosphorus removal agent and high-efficiency technology, applied in the field of water treatment, can solve the problems of poor stability of the compound phosphorus removal agent, affect the phosphorus removal effect, and affect the color of the water body, so as to improve the basicity and stability, and improve the phosphorus removal Effect, the effect of reducing the chroma of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

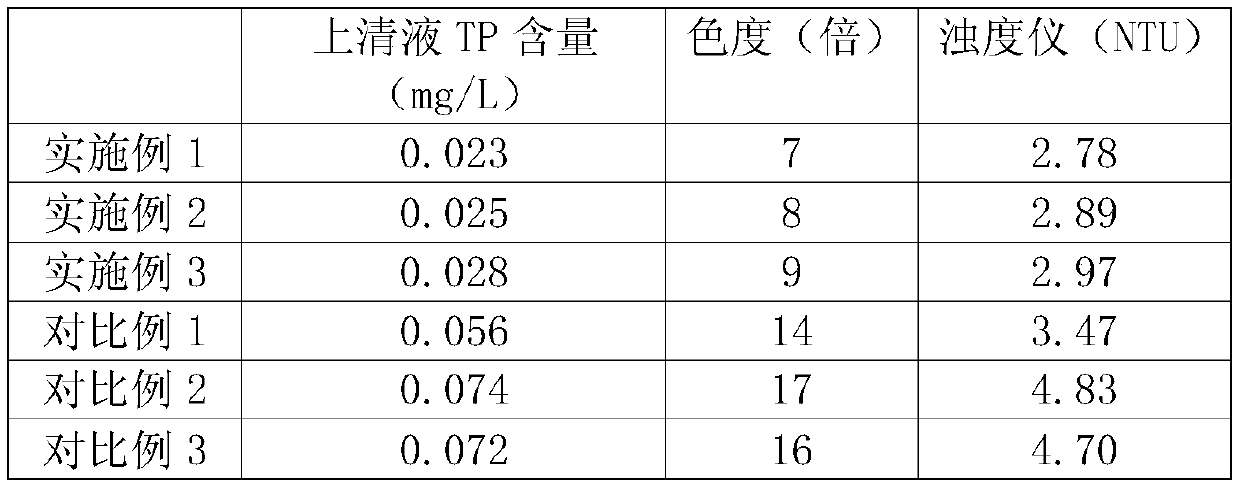

Examples

Embodiment 1

[0018] Put ferrous chloride and iron filings into water, stir evenly to obtain a mixed solution containing iron, use hydrochloric acid to adjust the pH of the mixed solution within 0.5, and then add hydrogen peroxide to the mixed solution to make Fe 2+ Completely oxidized to obtain a ferric chloride solution; add polyaluminum chloride and phosphate to the ferric chloride solution, stir evenly, and use liquid caustic soda to adjust the pH of the solution to 1 to obtain a high-efficiency composite dephosphorization agent. The content of iron element in the phosphorus agent is 11wt.%, the material ratio of iron element and aluminum element is 2:8, the ratio of the material amount of phosphate to the sum of the material amount of iron element and aluminum element is 0.02.

[0019] The high-efficiency composite phosphorus removal agent prepared in this example has a basicity of 50%. The high-efficiency composite phosphorus removal agent prepared in this example was left to stand for...

Embodiment 2

[0021] Put ferrous chloride and iron filings into water, stir evenly to obtain a mixed solution containing iron, use hydrochloric acid to adjust the pH of the mixed solution within 0.5, and then add hydrogen peroxide to the mixed solution to make Fe 2+ Completely oxidized to obtain ferric chloride solution; add polyaluminium chloride and borate to the ferric chloride solution, stir evenly, use liquid caustic soda to adjust the pH of the solution to 2 to obtain a high-efficiency composite dephosphorization agent, the high-efficiency composite The content of iron element in the dephosphorization agent is 11wt.%, the material ratio of iron element and aluminum element is 4:6, and the ratio of the material amount of borate to the sum of the amount of iron element and aluminum element is 0.08.

[0022] The salinity of the high-efficiency composite phosphorus removal agent prepared in this example is 45%. The high-efficiency composite phosphorus removal agent prepared in this example...

Embodiment 3

[0024] Put ferrous chloride and iron filings into water, stir evenly to obtain a mixed solution containing iron, use hydrochloric acid to adjust the pH of the mixed solution within 0.5, and then add hydrogen peroxide to the mixed solution to make Fe 2+ Completely oxidized ferric chloride solution.

[0025] Add polyaluminum chloride and silicate to the ferric chloride solution, stir evenly, adjust the pH of the solution to 2.5 with liquid caustic soda to obtain a high-efficiency composite phosphorus removal agent, and the iron element content in the high-efficiency composite phosphorus removal agent is 11wt.%. , the material ratio of the iron element to the aluminum element is 7:3, and the ratio of the material amount of the silicate to the sum of the material amounts of the iron element and the aluminum element is 0.15.

[0026] The salinity of the high-efficiency composite phosphorus removal agent prepared in this example is 40%. The high-efficiency composite phosphorus remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com